If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

A copper concentrator is an industrial processing plant that upgrades run-of-mine (ROM) copper ore to a much higher-grade copper concentrate, typically containing 20–30% Cu or more.

Its purpose is simple but critical:

Increase ore grade

Reduce the mass sent to smelting

Improve economic returns

Lower transportation and downstream processing costs

In today’s mining environment—with declining ore grades, deeper deposits, and complex mineralogy—the design and performance of a concentrator have a direct impact on:

Recovery rate

Total operating cost

Energy efficiency

Environmental compliance

Return on investment

This is why mining companies and investors pay close attention when developing new concentrator projects.

An efficient concentrator is not determined by equipment alone. Flow design must match ore characteristics, production targets, and investor expectations. Key design considerations include:

The flowsheet is dictated by the ore. Key parameters include mineralogy (sulphide vs. oxide), hardness/abrasiveness (Bond Work Index), clay content ("slimes" that affect rheology), and flotation response. A comprehensive metallurgical testwork program is non-negotiable.

The target throughput defines the scale of all equipment, from crusher feed openings to mill dimensions and flotation cell volumes. Design must balance peak capacity with average operational flexibility.

While typical copper recoveries range from 85% to 94% for sulphide ores, the design must optimize every unit operation to chase percentage points, as each 1% gain has a massive impact on revenue.

Grinding can consume over 50% of a site's energy. Design choices like High-Pressure Grinding Rolls (HPGR) for crushing, larger, more efficient mill drives, and optimized pump systems are critical for OPEX reduction.

In water-scarce regions, a highly efficient water recovery circuit is vital. Thickener performance and clear water return systems are designed to maximize water recycling, minimizing freshwater intake.

Modern plants are built as digital twins. Advanced Process Control (APC), online analyzers (e.g., for elemental assay), and IoT sensors allow for real-time optimization, stable operation, and predictive maintenance.

Design must integrate best available techniques (BAT) for tailings management, dust suppression, noise control, and chemical handling from day one, ensuring social license to operate.

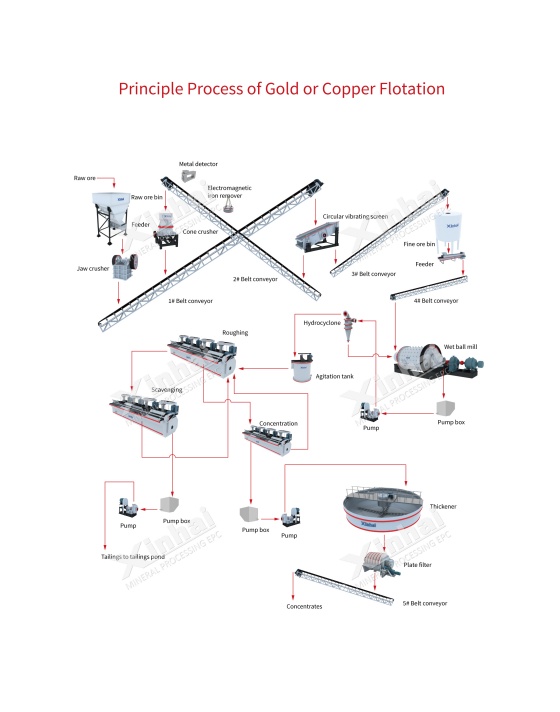

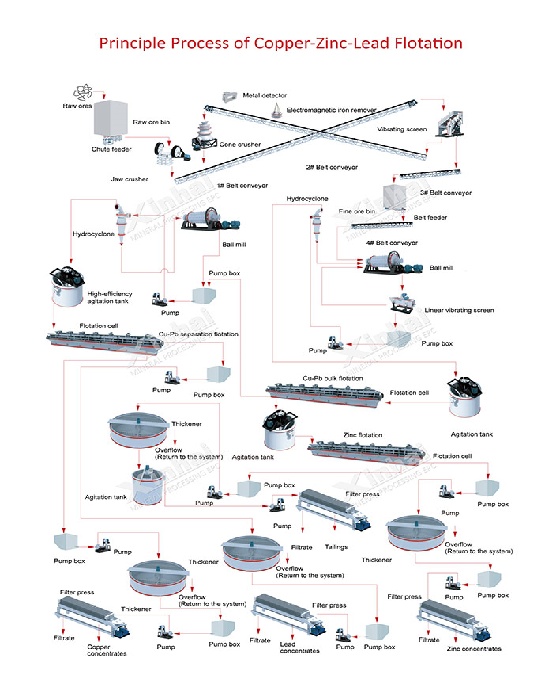

A complete concentrator requires coordinated equipment across multiple stages. Below is a typical equipment list.

Primary Jaw Crusher: For initial size reduction of ROM ore.

Secondary & Tertiary Cone Crushers: For further size reduction in closed-circuit with screens.

SAG/Ball Mill or Rod Mill/Ball Mill Combination: The workhorses for liberation. Selection depends on ore competency and feed size.

Hydrocyclone Batteries: For precise particle size classification in closed grinding circuits.

Flotation Cells: A range of modern, energy-efficient, tank cells for roughing, scavenging, and cleaning duties. Supercharged air delivery systems are key.

Agitation Tanks: For conditioning slurry with reagents prior to flotation and for efficient mixing in leaching processes if applicable.

Efficient Thickeners: For solid-liquid separation of concentrates and tailings, featuring robust rake mechanisms and control systems.

Filter Press / Disc Filter: For final dewatering of concentrate to a transportable cake. Membrane filter presses are preferred for lowest moisture.

Tailings Dry Stacking System: An integrated system often featuring deep cone paste thickeners and high-pressure filter presses to transform tailings into a stable, stackable solid.

This equipment list can be tailored based on ore type, plant capacity, and investor requirements.

The cost of constructing a copper concentrator varies enormously based on capacity, country, logistics, and ore complexity. Here is a practical breakdown.

Includes:

Engineering and design

Civil construction

Mechanical & electrical installation

Equipment procurement

EPC contract cost

Commissioning and training

Indicative ranges:

Small plant (300–1,000 TPD): USD 5–25 million

Medium plant (1,000–8,000 TPD): USD 25–150 million

Large plant (10,000+ TPD): USD 150–600+ million

Main items include:

Power consumption (largest proportion)

Grinding media

Flotation reagents

Maintenance and spare parts

Labor

Water management

Grinding alone often accounts for 30–40% of OPEX.

Hard ore → higher grinding cost

High clay → complex flotation, more reagents

Remote location → expensive logistics

Strict environmental laws → high tailings cost

Crushing → Grinding (Ball Mill) → Cu Rougher/Scavenger Flotation → Cu Cleaner Flotation (2-3 stages) → Concentrate Thickening & Filtration.

Best for: Clean, simple copper sulphide ores (e.g., chalcopyrite).

Crushing → Grinding → Bulk Cu-Mo Rougher Flotation → Regrind of Bulk Concentrate → Mo Separation Circuit (using depressants for copper) → Separate Cu and Mo Concentrate Dewatering.

Best for: Porphyry copper deposits with molybdenum credits.

Crushing → Grinding (with careful size control to avoid slime generation) → Desliming → Flotation with tailored reagent scheme (may include staged flotation or selective flocculation) → Enhanced cleaning stages.

Best for: Ores with high clay content, fine grain liberation, or complex mineral associations.

A 1500 TPD copper concentrator was designed and built by our engineering team in Pakistan.

Key highlights:

Ore type: Medium-hard copper sulfide ore.The raw ore has a copper grade of 0.80%.

Target concentrate grade: 23–25% Cu

Final recovery rate after commissioning: 90.05%

Full-process equipment provided: Crushing and screening → Grinding and classification → Flotation → Concentrate dewatering

Construction period: 10 months

Tailings dry stacking system ensured environmental compliance

The plant has been running steadily and helped the client reduce OPEX by 12% through optimized flowsheet design.

Another copper mine EPC project under construction: 1.5 Mtpa Copper Mine EPC Project in Kazakhstan

Choosing a full-process EPC contractor provides significant advantages:

One-stop engineering + equipment + installation

Faster construction timeline

Lower procurement cost

Unified process control and optimization

Reduced interface risks

Superior commissioning performance

Working with an experienced EPC provider ensures that the concentrator performs as designed and achieves the expected recovery and production targets.

Just drop us a line here → [Contact Our Engineering Team] ← book a quick call, send over whatever assay sheets or testwork you’ve got lying around, and we’ll run a proper, no-strings-attached review of your project for free.

Xinhai Mining has been around the block forever, building mineral processing plants and full EPC services all over the planet. We’ve done a ridiculous number of copper concentrators that actually work—higher recoveries, lower bills, and none of that old-school environmental mess. Pretty much anywhere there’s copper in the ground, chances are we’ve already helped someone dig it out cleaner and cheaper than they thought possible.