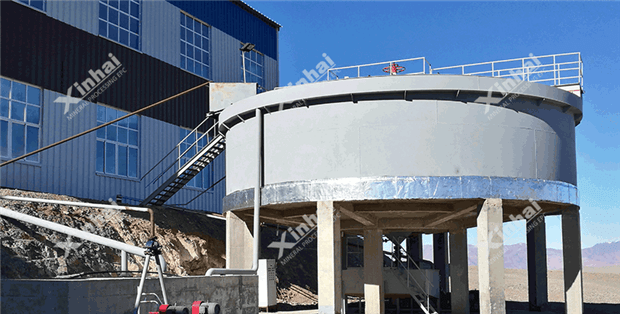

Concentrator equipment with new mechanical structure design. 【Processing capacity】: 5-1400t/d 【Scope of application】: It is widely used in the treatment of sludge, waste water and waste residue in metallurgy, mining, chemical industry, building materials, environmental protection and other departments.

Add flocculant to increase the particle size of settled solid particles, thereby speeding up the settling speed;

Add a degassing tank to prevent solid particles from adhering to air bubbles;

There is a receiving tray, and the feeding tube moves down, so that the fed ore slurry falls evenly and smoothly, and effectively prevents the occurrence of flower turning;

The unit processing capacity is 4 to 9 times that of conventional thickeners, and calculated on the basis of unit processing capacity, it saves 30% of energy consumption compared with traditional thickeners;

Flocculant addition system, flocculant addition automatic control system and high-efficiency thickener automatic control system can be additionally provided.

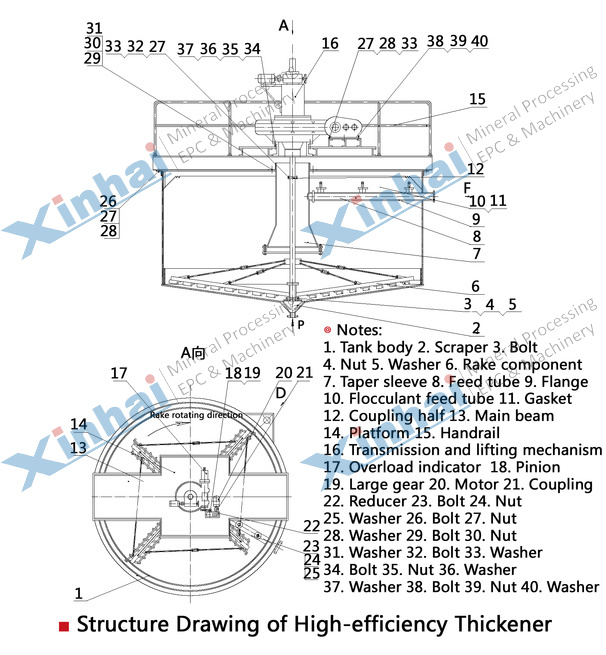

This thickener consists of the round thickener and harrow scrapping machine, the solid particles are suspended in thickener settling by gravity, the pulp in the upper turns into clean water so that the separation can be realized. The slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

| Model | Inner Diameter of Tank (mm) | Tank Height (mm) | Subsidence Area (m2) | Rabble Rotating Speed (r/min) | Lifting Height of the Rabble (mm) | Driving Motor Model | Driving Motor Power (kW) | Lifting Motor Model | Lifting Motor Power (kW) | Steel Tank Weight (kg) | Weight (kg) |

| GX-3.6 | 3600 | 1700 | 10.2 | 1.1 | 200 | Y100L-6 | 1.5 | Y100L-6 | 1.5 | 2829 | 6650 |

| GX-5.18 | 5182 | 2134 | 21 | 0.4 | 300 | Y132S-6 | 3 | PZ0.8AB | 0.8 | 5342 | 10460 |

| GX-6 | 6000 | 2500 | 28.3 | 0.8 | 300 | Y132M1-6 | 4 | Y132S-8 | 2.2 | 6506 | 10573 |

| GX-7.5 | 7500 | 2800 | 44.1 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 10258 | 17320 |

| GX-9 | 9000 | 2800 | 63.6 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 15980 | 23680 |

| GX-12 | 12000 | 3600 | 110 | 0.35 | 300 | Y132M-4 | 7.5 | Y100L1-4 | 2.2 | 25589 | 42756 |

| GX-15 | 15000 | 4000 | 177 | 0.15 | 300 | YCT200-4B | 7.5 | Y112M-6 | 2.2 | 36050 | 59000 |

| GX-18 | 18000 | 4400 | 254 | 0.13 | 400 | YCT200-4B | 7.5 | YTC752A-44 | 5.5 | 52485 | 73296 |

| GX-20 | 20000 | 4400 | 314 | 0.13 | 400 | YCT200-4B | 7.5 | YTC752A-44 | 5.5 | 59365 | 76020 |

During the concentration process of a concentrator, an additional pharmaceutical system needs to be equipped, which increases the cost and also increases the loss. The high-efficiency concentrator can provide flocculant and other pharmaceutical addition systems, and the supporting role between facilities is more obvious. In addition, the new mechanical structure increases the flocculation effect of the flocculant on the solid particles. While convenient and efficient, costs are controlled to a certain extent.