A thickener with central hydraulic motor drive and hydraulic automatic raking. 【Processing capacity】: 28~1590 m² 【Scope of application】: It is mainly used for clarification and concentration of mine pulp to achieve the purpose of dehydration. It can also be used for dehydration of solid-liquid separation in chemical, metallurgical and other industries.

Xinhai transmission thickener has large processing capacity and high concentration efficiency;

Hydraulic drive with overload protection function;

The core PLC automatically senses the pressure sensor signal to realize hydraulic automatic raking;

The transmission device has a simple structure and is easy to maintain;

Can be equipped with automatic dosing system.

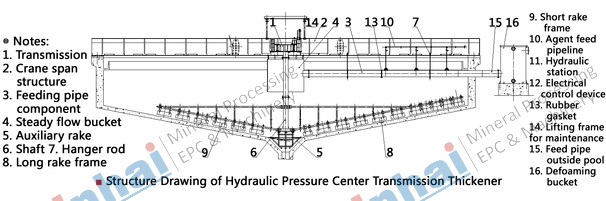

It is mainly composed of transmission device, bridge frame, dosing device, feed pipe, fixed tube, cloth tube, scraper, shaft, long rake, short rake, boom, electric control device, hydraulic station, maintenance hanger, etc. This thickener adopts flocculation technology. The slurry is directly input into the compression zone of the thickener to form a filter bed in the pool. The fine particles in the slurry input from the bottom that are not flocculated are washed up by the water flow through the filter bed layer. The particles in the layer collide with other particles and sink together due to the effect of the flocculant, thereby increasing the slurry concentration of the bottom layer, while the concentration of the overflow water in the upper layer decreases. Due to the use of the flocculant, the particles are easy to form agglomerates and the settling speed is high The rate is accelerated, and the processing capacity per unit area is significantly improved, which is 4 to 8 times that of the traditional thickener.

Mainly used for clarification and concentration of coal slurry or pulp, also used for dewatering of solid-liquid separation in chemical industry, metallurgy industry, etc.

| Model | Thickening Tank Diameter (m) | Thickening Tank Center Depth (m) | Subsidence Area (m2) | Time of Harrow Rack Rotation (min) | Height of Lifting Harrow (mm) | Capacity (t/d) | Drive Power (kW) |

| NZY-6 | 6 | 3 ~3.2 | 28 | 2.5 ~5 | 350 | 50~100 | 3 |

| NZY-9 | 9 | 3.5~3.8 | 63.6 | 3~5 | 350 | 120~175 | 3 |

| NZY-12 | 12 | 3.5~3.8 | 113 | 4~7 | 350 | 200~300 | 4 |

| NZY-15 | 15 | 4 ~4.5 | 176 | 5~10 | 450 | 350~400 | 5.5 |

| NZY-18 | 18 | 4 ~4.5 | 254 | 8~12 | 450 | 600~800 | 5.5 |

| NZY-20 | 20 | 4 ~4.5 | 314 | 8~12 | 450 | 800~1000 | 7.5 |

| NZY-24 | 24 | 4.5~5.5 | 450 | 9~12 | 450 | 1000~1300 | 7.5 |

| NZY-30 | 30 | 4.5~5.5 | 706 | 10 ~14 | 450 | 1500~1800 | 11 |

| NZY-38 | 38 | 6.5 ~8 | 1134 | 15 ~22 | 600 | 1800~2200 | 15 |

| NZY-40 | 40 | 6.5 ~8 | 1256 | 15 ~22 | 600 | 2200~2400 | 15 |

| NZY-45 | 45 | 6.5 ~8 | 1590 | 15 ~22 | 600 | 2400~2800 | 15 |

| NZY-53 | 53 | 6.5 ~8 | 2206 | 15 ~22 | 600 | 3000~3500 | 15 |

| NZY-60 | 60 | 7 ~8.5 | 2827 | 16~50 | 600 | 3500~5000 | 18.5 |

| NZY-75 | 75 | 8~10 | 4418 | 20 ~80 | 800 | 7500~10000 | 22 |

| NZY-100 | 100 | 8~10 | 7853 | 35~80 | 800 | 10000~15000 | 30 |

The concentration equipment of the new gold mine cyanidation plant adopts an ordinary central drive thickener, and the processing capacity has not reached the expected target. On this basis, two improved hydraulic center drive high-efficiency thickeners are added. Hydraulic type, larger processing capacity and high concentration efficiency; in addition, the core PLC automatically senses pressure sensing signals to realize hydraulic automatic raking, with high production efficiency. Ultimately more efficient pressing into the concentration target.