The XHC Series Jaw Crusher is a globally recognized high-performance crushing equipment. Featuring high-strength alloy cast steel key components and precision spherical roller bearings, combined with advanced crushing chamber design and optimized kinematics, the XHC Series ensures sustained high uptime, large throughput, efficient crushing, and low operating costs when handling hard, abrasive rocks as well as various recycled materials. It provides users with a stable, reliable, and cost-effective crushing solution. 【Processing capacity】: 40~1435t/h 【Scope of application】: With its innovative design concept and superior manufacturing quality, it delivers outstanding performance in coarse and medium crushing operations across metallurgy, mining, building materials, chemical, and cement industries.

Integrated motor base design

The crusher body and motor base are designed as a single integrated unit, fundamentally preventing

drive-system misalignment or damage caused by continuous vibration. This design not only improves

operational stability but also reduces foundation strength requirements—lowering civil costs—and

considerably shortens on-site installation and commissioning time, accelerating project startup.

Deep V-shaped crushing chamber and optimized motion trajectory

Based on discrete-element material breakage simulation and kinematic analysis, the XHC Series utilizes

an efficient deep V-shaped crushing chamber. The movable jaw's motion trajectory and crushing stroke

are scientifically matched to enhance material bite and breakage, achieving higher crushing efficiency

and better particle shape while reasonably controlling inertia to ensure smoother operation.

Optimized dynamic balance of the counterweight system

Through professional dynamic-simulation calculations, the flywheel and counterweights are precisely

balanced to significantly reduce unbalanced inertial forces during operation. This lessens impact on

bearings and the frame, thereby extending overall equipment life and ensuring reliable long-term

continuous operation.

Elastic vibration-damping foundation

A recommended elastic vibration-damping foundation effectively absorbs and isolates vibration energy

transmitted to the base. This both protects the plant structure and further lowers civil-engineering

requirements and costs—especially suitable for vibration-sensitive or multi-storey plant layouts.

Flexible and fast discharge-opening adjustment

Two discharge-opening adjustment options are provided: mechanical wedge adjustment and hydraulic

cylinder adjustment. Users may choose according to maintenance frequency and automation requirements.

Both methods offer simple operation, accurate positioning, and reliable safety. Gap adjustments can be

completed quickly, improving plant flexibility and maintenance efficiency.

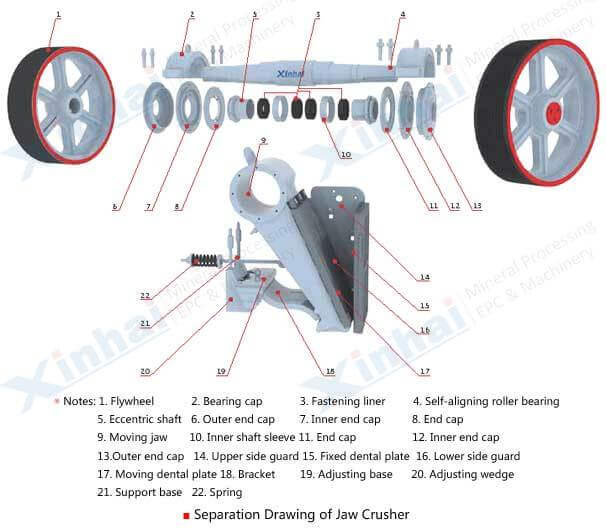

The motor transmits power through belt, drives the moving jaw to do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw, and the material will be crushed in multiple ways. The angle of jaw crusher between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw of jaw crusher moves away from fixed jaw by the pulling force of rod and spring, the products after crushing will be discharged from the outlet of jaw crusher.

| Model | Weight (kg) |

Feed Opening Width(mm) | Feeding Depth(mm) | Maximum Feed Size(mm) | Power(kW) | Discharge Opening Adjustment Range(mm) | Spindle Speed(rpm) |

| XHC63 | 7400 | 630 | 440 | 360 | 45 | 40-100 | 340 |

| XHC80 | 9500 | 800 | 510 | 420 | 75 | 40-175 | 350 |

| XHC96 | 11900 | 930 | 580 | 480 | 90 | 60-175 | 330 |

| XHC100 | 23300 | 1000 | 760 | 620 | 110 | 70-200 | 260 |

| XHC106 | 17100 | 1060 | 560 | 580 | 110 | 70-200 | 280 |

| XHC110 | 29500 | 1100 | 850 | 700 | 160 | 70-200 | 230 |

| XHC116 | 21500 | 1150 | 800 | 660 | 132 | 70-200 | 260 |

| XHC120 | 29500 | 1200 | 870 | 720 | 160 | 70-175 | 230 |

| XHC125 | 43900 | 1250 | 950 | 780 | 160 | 100-250 | 220 |

| XHC130 | 44000 | 1300 | 1000 | 820 | 160 | 100-250 | 220 |

| XHC140 | 54000 | 1400 | 1070 | 880 | 200 | 125-250 | 220 |

| XHC150 | 61500 | 1400 | 1200 | 1000 | 200 | 125-250 | 220 |

| XHC160 | 88500 | 1600 | 1200 | 1000 | 250 | 150-300 | 220 |

| XHC200 | 137500 | 2000 | 1500 | 1300 | 400 | 175-300 | 200 |

| XHC3054 | 30300 | 1375 | 760 | 630 | 160 | 70-200 | 260 |

| Model | Each Discharge Port CSS(mm)Corresponding Output(t/h) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | |

| XHC63 | 40-45 | 55-60 | 65-70 | 80-90 | 95-105 | 110-120 | 120-135 | ||||||||

| XHC80 | 55-75 | 65-95 | 80-110 | 95-135 | 110-150 | 125-175 | 140-190 | 175-245 | 210-290 | 245-335 | |||||

| XHC96 | 105-135 | 125-155 | 140-180 | 160-200 | 175-225 | 220-280 | 265-335 | 310-390) | |||||||

| XHC100 | 125-175 | 145-200 | 160-220 | 180-250 | 220-310 | 265-365 | 310-430 | 355-490 | |||||||

| XHC106 | 150-185 | 165-215 | 190-235 | 205-265 | 255-325 | 305-385 | 355-450 | 395-500 | |||||||

| XHC110 | 160-220 | 175-245 | 190-275 | 215-295 | 260-360 | 310-430 | 350-490 | 405-555 | |||||||

| XHC116 | 165-205 | 180-235 | 205-255 | 225-285 | 270-345 | 320-405 | 370-465 | 410-520 | |||||||

| XHC120 | 175-240 | 195-270 | 210-305 | 235-325 | 285-395 | 340-475 | 385-540 | ||||||||

| XHC125 | 245-335 | 295-405 | 345-475 | 395-545 | 445-615 | 495-685 | 545-755 | ||||||||

| XHC130 | 270-369 | 325-446 | 380-523 | 435-600 | 490-677 | 545-754 | 600-831 | ||||||||

| XHC140 | 325-445 | 380-530 | 435-605 | 495-685 | 550-760 | 610-840 | |||||||||

| XHC150 | 340-470 | 400-555 | 460-635 | 520-720 | 580-800 | 640-880 | |||||||||

| XHC160 | 430-610 | 495-695 | 560-790 | 625-880 | 685-965 | 745-1055 | 815-1145 | ||||||||

| XHC200 | 630-890 | 710-1000 | 785-1105 | 865-1215 | 940-1320 | 1015-1435 | |||||||||

| XHC3054 | 210-270 | 240-300 | 260-330 | 285-365 | 345-435 | 405-515 | 465-595 | 530-670 | |||||||

Capacity Note:The data in the table apply under the following conditions: material bulk density of 2.7 t/m³, feed material pre-screened, 100% of feed size less than the maximum feed size, 80% less than 0.5 times the maximum feed size, and 50% less than 0.2 times the maximum feed size, with open-circuit operation. The crusher’s performance depends not only on its inherent parameters but also on the properties of the material being processed, as well as the proper selection and operation of auxiliary equipment such as feeders, belt conveyors, and hoppers within the entire production line.

During the cooperation between a gold mine processing plant in Jiangxi and Xinhai jaw crusher manufacturer, Xinhai customized the jaw crusher for the customer according to the customer's high hardness of ore and complete supporting facilities for medium and fine crushing. The deep cavity of the crusher added a new type of high manganese Steel, optimized design mechanism, the crushing efficiency during use is 15% higher than that of the previously selected crusher, and the service life is extended by half a year; the cavity is deepened, and a discharge device is added to the discharge port, the material port blockage rate is almost zero, and the application effect Better, loved by customers.