A grinding equipment that uses steel rods as grinding media. 【Processing capacity】: 0.62~250t/h 【Scope of application】: Rod mills are mainly used for rough grinding operations. It is suitable for fine crushing and coarse grinding of ore in the first stage of open-circuit grinding, especially for handling brittle materials.

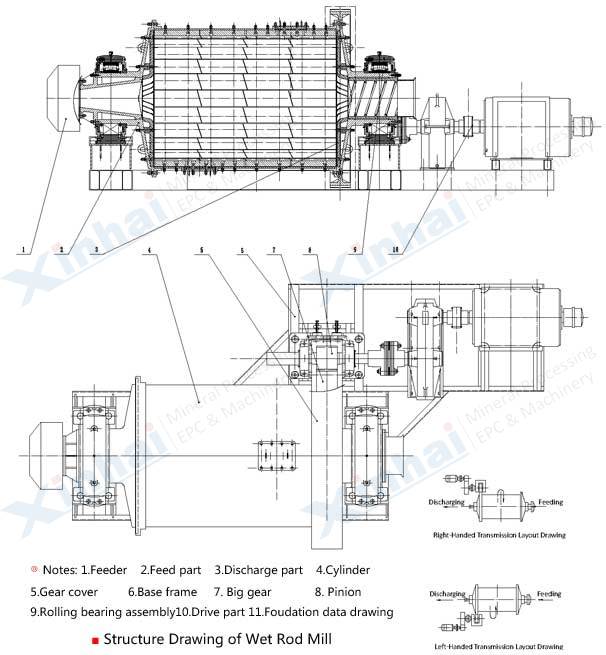

The conical end cover of the rod mill has a small curvature, which enables the steel rod to move regularly in the mill;

The diameter of the ore-discharging hollow shaft is larger, which is convenient for maintenance, and at the same time, it can reduce the ore slurry level and quickly discharge the ore;

Under normal circumstances, the feeding particle size range of the rod mill is 20~30mm, and the product particle size can generally reach 0~3mm;

The rod mill grinds the material with the full length of the steel rod, with uniform force, uniform product particle size, and less over-grinding.

(1) Rod mill is usually selected in order to prevent over-grinding in gravity or magnetic separation plant of tungsten tin and other rare metals mine;

(2) In two stages grinding, the capacity of rod mill in the first stage grinding is larger than that of ball mill;

(3) In some cases, rod mill can replace short head cone crusher.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Motor Revolution (r/min) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective Volume (m3) | Weight (kg) |

| MBY0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBYg0924 | 900 | 2400 | Y225M-8 | 22 | 730 | 5001 | 1865 | 1400 | 0.81~4.3 | 1.2 | 6443 |

| MBY1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4 ~4.9 | 2.28 | 12308 |

| MBY1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7935 | 3185 | 2280 | 5 | 19990 | |

| MBYg1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4 ~7.5 | 5 | 21210 |

| MBYg2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14 ~35 | 9 | 42123.5 |

| MBYg2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43 ~61 | 10.8 | 45800.5 |

| MBYg2430 | 2400 | 3000 | JR138-8 | 280 | 735 | 9004.5 | 4836.4 | 3490 | 11.5 | 55795 | |

| MBYg2732 | 2700 | 3200 | JR157-8 | 320 | 750 | 10509 | 5000 | 3620 | 15.7 | 83110 | |

| MBYg2736 | 2700 | 3600 | JR1510-8 | 380 | 743 | 10764 | 5150 | 3620 | 32 ~86 | 17.7 | 90441 |

| MBY2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |

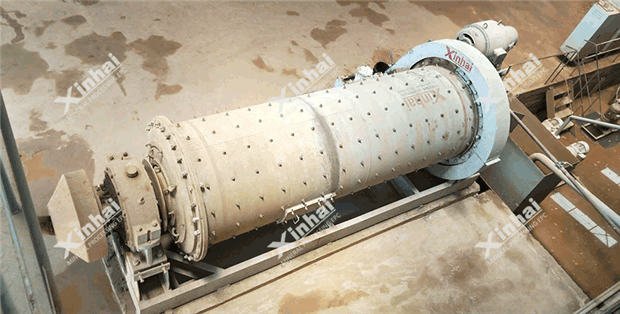

In a concentrator, the ore from the grinding system contains water and mud, and the particle size varies greatly. In the case of an open circuit, the grinding efficiency is relatively low, the quality of the discharged material is relatively poor, and it is far from reaching the predetermined target. Xinhai's wet rod mill is adopted. Due to the small curvature of the conical section cover, the steel rod moves regularly, and the grinding particle size of the steel rod is more uniform. Finally, the problem of the beneficiation plant is solved, so that the beneficiation work can be completed efficiently within a given time.