An Overflow Ball Mill is a machine that grinds ore into smaller bits in mineral plants. Unlike the grate discharge mill, it doesn’t have a grate at the end. Instead, it uses a simple trick: when the mix of ore and water—called slurry—gets high enough, it spills over a lip and flows out. This setup is awesome for fine grinding, especially as the last step in a grinding line. It makes sure the ore is tiny enough to pull out valuable minerals. 【Processing capacity】: 0.17~170t/h 【Scope of application】: This kind of wet overflow ball mill is often used for grinding fine ores.

Simple Setup & Tough Build: No grates to get clogged or worn out. This means fewer breakdowns and less fixing.

Super Fine Grind: Great for making tiny particles, often under 200 mesh, which helps free up tricky minerals.

Steady Results: Gives you a smooth, even product without big chunks sneaking through.

Easier Setup: The discharge system needs less fancy foundation work than grate mills.

EEnergy-Saving Ball Mill:Modern Overflow Ball Mills are often energy-saving ball mills. They use high-tech motors and smart controls to tweak the load and speed. This cuts down on power use, which is a huge cost. In a Peru mine, they swapped to an energy-saving mill and dropped their power bill by 12%.

Fine Grinding Efficiency:The long grinding time and tumbling balls make the Overflow Ball Mill great at fine grinding efficiency. It creates lots of surface area on the ore, which helps pull out more minerals later. This is why it’s a go-to for tough jobs like gold or copper processing.

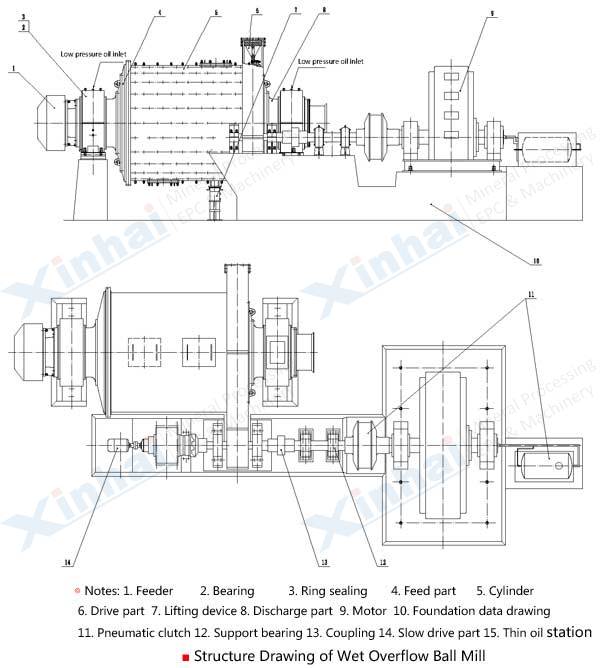

It’s a big, horizontal cylinder that spins on its axis. Heavy bearings and trunnions hold it up.

Cylinder Shell:The main body, made from super strong steel.

Liners:Tough plates bolted inside to protect the shell from wear. They’re designed to lift the balls just right.

Grinding Media:The steel balls that do the actual grinding. Their size depends on the ore type.

Feed End:The spot where the slurry enters, through a trunnion.

Bearings & Trunnions:These keep the mill spinning smoothly and support its heavy load.

Discharge Part:This is the key piece. The discharge trunnion is a hollow, trumpet-shaped part with a lip that controls how much slurry stays inside. It’s what makes the overflow happen.

Cylinder Design:The cylinder’s built to handle constant spinning, heavy balls, and rough ore. Its length and width are set to match the grinding job. Longer cylinders usually mean a finer grind. For instance, a copper mine in Chile uses a 6m-long mill to get super fine particles for flotation.

The mill is a big, spinning cylinder half-filled with grinding balls, usually tough steel ones. As it turns, the balls get lifted by ridges inside the cylinder. Then, they tumble down, smashing and grinding the ore through bangs and scrapes. The slurry—ore mixed with water—flows in one end. The spinning and new slurry push the ground stuff toward the other end.

Here’s what makes it special: the discharge end. There’s no grate, just a hollow opening called a trunnion. The slurry builds up until it’s higher than the trunnion’s edge, like water spilling over a dam. Only the fine bits float out with the water. Bigger chunks stay inside for more grinding. This keeps things smooth and consistent.

This setup makes the Overflow Ball Mill a champ at fine grinding. The ore stays in longer than in grate mills, so it gets ground down more. Only tiny particles sneak out over the edge. This makes a super fine, even product—perfect for stuff like flotation later on. For example, in a gold mine in Australia, they used an Overflow Ball Mill to grind ore to under 200 mesh, boosting gold recovery by 10%.

| Feature | Overflow Ball Mill | Grid Ball Mill |

|---|---|---|

| Discharge Mechanism | Overflow weir - slurry discharges when level exceeds weir height | Grate plates with lifters - slurry passes through grate openings |

| Product Size | Finer, more uniform grind | Coarser grind with wider size distribution |

| Capacity | Generally lower for same mill size | Higher throughput due to faster discharge |

| Maintenance | Lower - no grates to wear or clog | Higher - grates require regular replacement |

| Risk of Blinding | Very low | Higher with clayey or fibrous ores |

| Installation Height | Lower | Higher due to discharge mechanism |

| Ideal Application | Fine grinding, regrinding, precious metals | Coarse grinding, primary grinding stage |

In gold mining, you need a super fine grind to free tiny gold bits for leaching. The Overflow Ball Mill nails this, making sure you get the most gold out. A mine in Ghana used one to grind ore so fine it upped their recovery by 8%.

For copper ores with minerals spread thin, the Overflow Ball Mill grinds fine enough for flotation to work well. This boosts the copper you get out. A mine in Zambia saw their copper grade improve by 5% thanks to this mill.

It’s not just gold and copper. The mill works for iron ore, lead-zinc, molybdenum, and nickel too. It’s often used for secondary grinding or regrinding, wherever you need a fine, controlled product. It’s like the Swiss Army knife of grinding!

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Length (mm) | Width (mm) | Height (mm) | Effective Volume (m3) | Max. Ball Load (t) | Weight (kg) |

| MQY0918 | 900 | 1800 | Y225M-8 | 22 | 5080 | 2300 | 2015 | 0.9 | 1.66 | 6078 |

| MQY1212 | 1200 | 1200 | Y225S-8 | 18.5 | 5788 | 2994 | 2540 | 1.14 | 2.4 | 11473 |

| MQY1224 | 1200 | 2400 | YR280S-8 | 55 | 6112 | 2794 | 2540 | 2.28 | 3.8 | 12308 |

| MQY1515 | 1500 | 1500 | JR115-8 | 60 | 5766 | 2945 | 2600 | 2.2 | 6.4 | 15424 |

| MQY1530 | 1500 | 3000 | JR125-8 | 95 | 7979 | 2945 | 2600 | 5 | 10 | 18690 |

| MQY2122 | 2100 | 2200 | JR128-8 | 155 | 8070 | 4840 | 3795 | 6.6 | 14 | 47800 |

| MQY2130 | 2100 | 3000 | JR137-8 | 210 | 8870 | 4840 | 3795 | 9 | 20 | 47220 |

| MQY2136 | 2100 | 3600 | JR137-8 | 210 | 9300 | 4840 | 3795 | 10.8 | 22 | 52010 |

| MQY2145 | 2100 | 4500 | JR148-6 | 310 | 11029 | 4738.6 | 3300 | 13.5 | 23.8 | 58305 |

| MQY2430 | 2400 | 3000 | JR1410-8 | 280 | 9710 | 4778 | 4120 | 12.1 | 23 | 65880 |

| MQY2721 | 2700 | 2100 | JR1410-8 | 280 | 9400 | 5600 | 4700 | 10.7 | 24 | 63900 |

| MQY2736 | 2700 | 3600 | TDMK400-32 | 400 | 13049 | 5800 | 4680 | 17.8 | 32 | 96570 |

| MQY2740 | 2700 | 4000 | TDMK400-32 | 400 | 11850 | 5667 | 4496 | 20.4 | 40 | 78800 |

| MQY3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6760 | 5150 | 21.4 | 45 | 107660 |

| MQY3245 | 3200 | 4500 | TDMK630-36 | 630 | 14356 | 7200 | 5152.5 | 32.8 | 65 | 130283 |

| MQY3254 | 3200 | 5400 | TM1000-36/2600 | 1000 | 15800 | 6760 | 5200 | 37.2 | 73 | 121000 |

| MQY3645 | 3600 | 4500 | TM1000-36/2600 | 1000 | 15000 | 7200 | 6326 | 41.8 | 76 | 135000 |

| MQY3650 | 3600 | 5000 | TM1250-40/3250 | 1250 | 17157 | 7755 | 6326 | 46.4 | 86 | 145000 |

| MQY3660 | 3600 | 6000 | TM1250-40/3250 | 1250 | 19000 | 7755 | 6326 | 55.7 | 102 | 154000 |

| MQY3690 | 3600 | 9000 | TDMK1800-30 | 1800 | 28000 | 4600 | 5600 | 83 | 163 | 212000 |

| MQY3867 | 3800 | 6700 | TDMK1600-30 | 1600 | 19000 | 8200 | 7100 | 70 | 130 | 186000 |

| MQY4067 | 4000 | 6700 | TDMK1800-30 | 1800 | 15600 | 9600 | 7300 | 78 | 138 | 207000 |

| MQY4561 | 4500 | 6100 | TDMK2200-30 | 2200 | 18200 | 10500 | 7600 | 93 | 151 | 238000 |

In the original production process of tungsten concentrate, in order to pursue a larger processing capacity, the second-stage grinding process used a grid-type ball mill. It was finally found that the output did not meet the standard, and the equipment was seriously worn out. Therefore, Xinhai's new wet overflow ball mill was used. This new type of ball mill does not require forced ore discharge, and the slurry overflows automatically, which reduces equipment consumption and energy consumption.

Xinhai Mining Technology & Equipment Inc. is a pro at delivering top-notch Overflow Ball Mills worldwide. They customize solutions, from single mills to full plant setups. For example, in a South American copper mine, their energy-saving Overflow Ball Mill with hydraulic couplings and smart controls cut energy use by 15% while keeping the grind super consistent. That’s the kind of result that makes miners smile.

Picking the right mill is tricky. It depends on your ore, how much you need to process, and your budget. Xinhai’s team of pros can help. They do tests and design plans to find the perfect Overflow Ball Mill setup for you. It’s all about getting the most bang for your buck.

Reach out to Xinhai for a private chat. Let them help you build a better, more profitable mineral processing plant.