A high-efficiency and energy-saving overflow ball mill equipment with rolling bearings. 【Processing capacity】: Up to 160t/h 【Scope of application】: Xinhai straight barrel ball mill is often used for grinding fine ores.

The transmission of the straight barrel type beneficiation ball mill adopts large double-row spherical roller bearings instead of sliding bearings, which greatly reduces the friction force, is easy to start, and saves 20-30% of energy;

The use of corrugated lining plate increases the contact surface of the ball ore, strengthens the grinding effect, and has the ability to lift the ore, reducing the energy consumption;

Large discharge port, large production capacity;

The small ball mill with a diameter of less than 2.1 meters (excluding 2.1 meters) adopts an integral frame, which is convenient for civil construction and equipment installation;

Oil mist lubrication device ensures reliable lubrication of large and small gears.

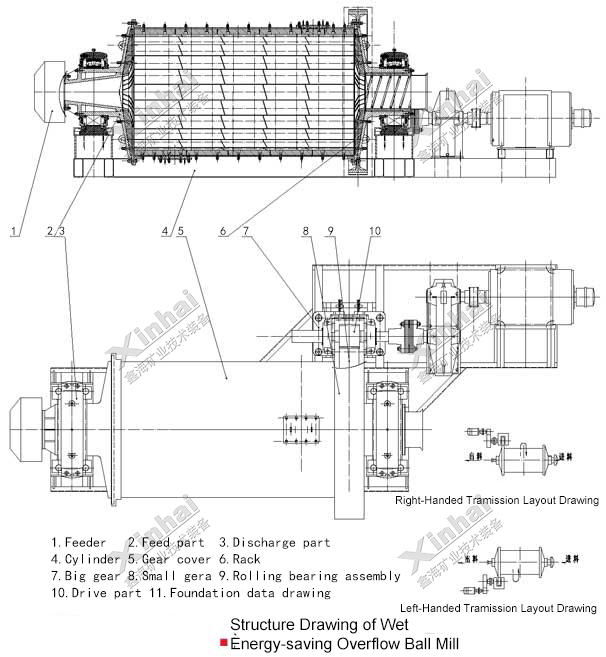

The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are backpitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With a simple structure, higher operation rate, and rolling bearing, the energy conservation is significant.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective Volume (m3) | Max. Ball Load (t) | Weight (kg) |

| MQYg 0912 | 900 | 1200 | Y1800L-6 | 15 | 3666 | 1835 | 1400 | 0.25〜1.2 | 0.7 | 1 | 4265 |

| MQYg 0918 | 900 | 1800 | Y225M-8 | 22 | 4401 | 2535 | 2070 | 0.25〜1.6 | 0.9 | 1.66 | 5235 |

| MQYg 1212 | 1200 | 1200 | Y225S-8 | 18.5 | 3512 | 2076 | 1620 | 0.17 〜4.1 | 1.14 | 1.9 | 9610 |

| MQYg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26〜6.15 | 2.4 | 4.6 | 12219 |

| MQYg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2412 | 1728 | 0.34 〜8.3 | 3.7 | 8 | 15940 |

| MQYg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 〜4.5 | 2.2 | 4.2 | 17125 |

| MQYg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 〜9 | 5 | 10 | 21129 |

| MQYg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 2.8 〜10 | 5.4 | 10 | 23933 |

| MQYg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5〜12.5 | 7 | 12 | 27500 |

| MQYg 1557 | 1500 | 5700 | JR127-8 | 130 | 10880 | 3254 | 2370 | 4.5 〜16 | 8.9 | 15 | 29359 |

| MQYg 1836 | 1800 | 3620 | JR136-8 | 180 | 8865 | 3683 | 2785 | 4.5 〜29 | 8.2 | 13.8 | 34970 |

| MQYg 1845 | 1800 | 4520 | JR137-8 | 210 | 9750 | 3683 | 2785 | 5〜33 | 10.2 | 19 | 37480 |

| MQYg 1857 | 1830 | 5720 | JR137-8 | 210 | 11009 | 3683 | 2785 | 6〜40 | 12.5 | 22 | 42096 |

| MQYg 1863 | 1800 | 6320 | JR138-8 | 320 | 11690 | 3781 | 2775 | 6〜45 | 14.2 | 25 | 45520.5 |

| MQYg 1870 | 1800 | 7020 | JR138-8 | 245 | 12599 | 3783 | 2735 | 7〜47 | 15 | 31.5 | 45136 |

| MQYg 1875 | 1800 | 7520 | JR138-8 | 245 | 12850 | 3783 | 2775 | 7.5 〜54 | 17 | 30 | 49450 |

| MQYg 2122 | 2100 | 2200 | JR128-8 | 155 | 7235 | 4120 | 3083 | 5〜29 | 6.6 | 20 | 35963 |

| MQYg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 〜36 | 9 | 27 | 40157 |

| MQYg 2136 | 2100 | 3600 | JR137-8 | 210 | 8958 | 4320 | 3025 | 7.5 〜42 | 10.8 | 23.5 | 44132.5 |

| MQYg 2145 | 2100 | 4500 | JR138-8 | 245 | 10350 | 4268 | 3121 | 10 〜45 | 13.5 | 23.6 | 42772 |

| MQYg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 〜92 | 11.5 | 22.5 | 57455.5 |

| MQYg 2436 | 2400 | 3600 | JR137-6 | 280 | 9623.5 | 4836.4 | 3490 | 8 〜110 | 13.8 | 25.5 | 60861.5 |

| MQYg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3440 | 8 〜130 | 16.5 | 31.5 | 63829.5 |

| MQYg 2445 | 2400 | 4500 | JR1510-8 | 380 | 11132.5 | 5091.4 | 4065 | 8.5 〜140 | 17.5 | 31 | 75923 |

| MQYg 2460 | 2400 | 6000 | JR1510-8 | 450 | 12623.5 | 5201.4 | 4060 | 9 〜180 | 23 | 40 | 83869 |

| MQYg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3620 | 7 〜110 | 13.8 | 29 | 66201 |

| MQYg 2730 | 2700 | 3000 | JR137-6 | 280 | 9201 | 4786.4 | 3620 | 8 〜115 | 15.3 | 32 | 72415 |

| MQYg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10729 | 5000 | 3620 | 8〜120 | 15.7 | 32 | 83110 |

| MQYg 2736 | 2700 | 3600 | JR158-8 | 380 | 10764 | 5150 | 3620 | 12〜145 | 17.7 | 37 | 90441 |

| MQYg 2740 | 2700 | 4000 | JR1510-8 | 380 | 10870 | 5050 | 3620 | 12.5 〜152 | 19 | 40 | 93537 |

| MQYg 2745 | 2700 | 4500 | JR1510-8 | 380 | 11664 | 5150 | 3620 | 12.5 〜163 | 20.5 | 40 | 96196 |

| MQYg 2747 | 2700 | 4700 | JR1510-8 | 450 | 11864 | 5150 | 3620 | 13〜170 | 23 | 45 | 97605 |

| MQYg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12550 | 6750 | 5150 | 14〜180 | 21.4 | 45 | 112430 |

| MQYg 3245 | 3200 | 4500 | TDMK630-36 | 630 | 13950 | 7200 | 5152.5 | 95〜110 | 32.8 | 65 | 141629 |

| MQYg 3660 | 3600 | 6000 | TDMK1250-40 | 1250 | 19780 | 7700 | 5496 | 120〜200 | 55 | 102 | 193483 |

A copper concentrator in Yunnan found that although the grinding efficiency of the pre-concentration work was high, the material particle size was large, the equipment wastage was heavy, and the cost remained high. After repeated discussions and selections, Xinhai's straight-tube energy-saving overflow ball mill was finally selected. Although the output has decreased, it still fully meets the needs of the selection plant. Moreover, Xinhai ball mill has good material, small wear, and simple structure. The lining plate increases the contact area of the ball and ore, strengthens the grinding effect, and reduces the energy consumption. Finally, the goal of reaching the target production and basic cost control will be achieved.