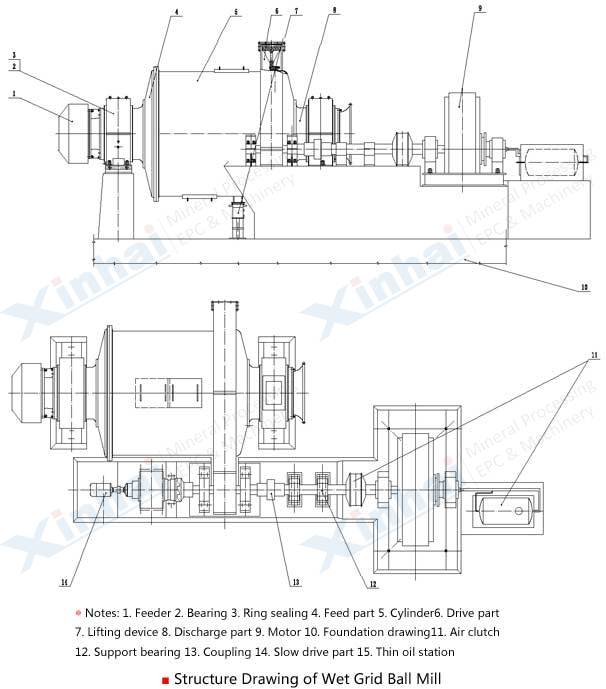

A traditional ball mill equipment that is forced to discharge ore by the ore discharge grid. 【Processing capacity】: 900mm~4500mm 【Scope of application】: This wet grid ball mill is often used for grinding coarse ores.

Jack up device for easy maintenance;

Static and dynamic pressure bearing, stable and reliable operation;

Slow transmission, easy to repair and start;

Oil mist lubricating device to ensure reliable lubrication of large and small gears;

Flexible start of gas clutch;

The barrel of the wet grid ball mill can be configured as a manganese steel lining plate or a rubber lining plate according to the requirements, which has good wear resistance, long service life and easy maintenance.

The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Length (mm) | Width (mm) | Height (mm) | Effective Volume (m3) | Max. Ball Load (t) | Weight (kg) |

| MQG0909 | 900 | 900 | Y225S-8 | 18.5 | 4750 | 2213 | 2050 | 0.45 | 0.96 | 4620 |

| MQG0918 | 900 | 1800 | Y225M-8 | 22 | 5000 | 2280 | 2050 | 0.9 | 1.92 | 5340 |

| MQG1212 | 1200 | 1200 | Y225M-8 | 22 | 5788 | 2994 | 2540 | 1.14 | 2.4 | 11438 |

| MQG1224 | 1200 | 2400 | Y315S-8 | 55 | 6673 | 2994 | 2540 | 2.28 | 3.96 | 13200 |

| MQG1515 | 1500 | 1500 | JR115-8 | 60 | 6094 | 3300 | 2766 | 2.5 | 5 | 13700 |

| MQG1530 | 1500 | 3000 | JR125--8 | 95 | 7979 | 3300 | 2766 | 5 | 10 | 18690 |

| MQG2122 | 2100 | 2200 | JR128-8 | 155 | 7750 | 4839 | 3794 | 6.6 | 15 | 45400 |

| MQG2130 | 2100 | 3000 | JR137-8 | 210 | 8744 | 4394.7 | 3110 | 9 | 20 | 45790 |

| MQG2430 | 2400 | 3000 | JR1410-8 | 280 | 9728 | 4956 | 4018 | 12.1 | 22.5 | 67000 |

| MQG2721 | 2700 | 2100 | JR1410-8 | 280 | 9300 | 5500 | 4500 | 10.7 | 24 | 63000 |

| MQG2727 | 2700 | 2700 | JR148-8 | 310 | 9900 | 5500 | 4500 | 13.8 | 29 | 68530 |

| MQG2736 | 2700 | 3600 | TDMK400-32/2150 | 400 | 9765 | 5826.6 | 4674.5 | 18.4 | 41 | 98020 |

| MQG3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5152.5 | 22.5 | 45 | 115103 |

| MQG3236 | 3200 | 3600 | TDMK630-36 | 630 | 14300 | 6760 | 5200 | 24.8 | 58 | 119012 |

| MQG3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 32.8 | 65 | 137589 |

| MQG3639 | 3600 | 3900 | TDMK1000-36/3600 | 1000 | 15000 | 7200 | 6300 | 36.2 | 75 | 145000 |

| MQG3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 15200 | 7750 | 6300 | 41.8 | 90 | 159700 |

| MQG3650 | 3600 | 5000 | TDMK1400-40 | 1400 | 17600 | 7750 | 6300 | 46.4 | 96 | 158000 |

| MQG3660 | 3600 | 6000 | TDMK1600-40 | 1600 | 17000 | 8800 | 6500 | 55.7 | 120 | 189000 |

| MQG4060 | 4000 | 6000 | TDMK1700-30 | 1700 | 17400 | 9500 | 7600 | 69.8 | 137 | 214000 |

| MQG4560 | 4500 | 6000 | TDMK2300-30 | 2300 | 17800 | 10500 | 7600 | 87 | 158 | 294000 |

In an iron ore processing plant in Yunnan, the hardness of the ore is large, and the grinding particle size is small. In order to avoid the over-grinding of the ore, Xinhai's wet grid type ball mill is selected in the grinding stage. Wet grid type ball mill is impacted and self-grinded by steel balls and ore itself, with high grinding efficiency, hydrostatic and dynamic pressure bearing, and stable and reliable cylinder operation, which is convenient for multiple grinding of materials in the cylinder. At the same time, the lubrication device between the large and small gears of the ball mill makes production higher efficiency. The ore slurry level is low, the ore discharge is timely, the energy consumption is reduced, and the ideal effect is achieved.