If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

When the processing capacity of a mineral processing plant becomes insufficient and requires expansion, or when the properties of the ore change significantly, the existing plant often needs to be upgraded or renovated. Compared with the construction of a new plant, renovation projects place greater demands on the design capabilities of the engineering company involved.

This is because such projects must take into account more complex factors, including site space limitations, integration of existing equipment and infrastructure with new systems, and compatibility with the layout and dimensions of original pipelines.

This article uses the CIL expansion project of a gold mine in Malaysia—undertaken by Xinhai—as an example to illustrate the overall renovation process.

This project is located in Malaysia. The original design capacity of the mineral processing plant was 500 tons per day (t/d), which could no longer meet the growing production demands. Therefore, the owner decided to undertake a renovation and expansion project to upgrade the plant’s processing capacity to 800 t/d. Xinhai Mining was entrusted with the EPC (Engineering, Procurement, and Construction) services, covering everything from design to implementation.

The core challenge of this expansion project was that the original plant layout and planning had not reserved space for future development, resulting in extremely limited site conditions.

To achieve the capacity upgrade, Xinhai ingeniously integrated key process equipment—such as ball mills, leaching and agitation tanks, and filter presses—within the constraints of the existing plant structure. At the same time, to accommodate the new equipment and optimize the process layout, the original plant was partially expanded, and several new auxiliary workshops were constructed.

New grinding and feeding system, including a belt conveyor (belt supplied by the customer)

New grinding and classification system

New concentration and classification pumps

Four newly installed leaching and agitation tanks

Re-laying of pipelines including slurry pipelines, air ducts, and water pipes

The redesigned process flow adopts a one-stage grinding, two-stage classification, and one-stage thickening scheme to produce slurry with a final grinding fineness of 85% passing -200 mesh.

(1) New Grinding and Classification System

The system follows a one-stage grinding and two-stage classification process. Grinding is performed using an MQYg2445 long-cylinder overflow ball mill.

The first-stage classification uses a spiral classifier (FLG2000). The classifier overflow enters the second-stage hydrocyclone for further classification, while the underflow (return sand) is sent back to the ball mill.

The second-stage classification adopts a hydrocyclone. The underflow returns to the ball mill, and the overflow goes to the desliming screen.

(2) Desliming Screen Upgrade

The desliming screen has been upgraded from the original linear screen (DZS0918) to a DZS1225 linear screen to address the problem of excessive coarse residue in the previous system.

(3) Renovation of the Leaching System

The core objective of the leaching system renovation was to increase leaching capacity (to match the new 800 t/d throughput), resolve air supply bottlenecks, and optimize process layout and pipeline specifications. The main modifications included:

·Expansion of Core Equipment: On top of the original six SJ7.0×7.5 leaching and agitation tanks, four additional tanks of similar specifications were installed (adjusted to φ7.0×7.0 for compatibility with existing units).

·Safety Screen Upgrade: The original safety screen was replaced with a larger DZS1225 linear screen to improve processing capacity and safety.

·Air Supply Enhancement: A new TRRE-250 high-pressure Roots blower was installed, fully resolving the insufficient air supply issue in tanks #5 and #6, and providing adequate airflow for the new leaching tanks and interstage carbon contact.

·Space Optimization and Installation: The existing safety screen platform and pipelines were horizontally shifted to the southwest to make space for four new tank foundations. Welding and installation of these tanks were successfully completed.

·Pipeline Upgrade: All leaching system pipelines were upgraded to DN200 welded steel pipes, replacing the original DN150 pipes for improved flow capacity and durability.

·Slurry Flow Adjustment: After passing through the new safety screen, the slurry could no longer rely on gravity flow due to insufficient height difference caused by the added tanks. A slurry pump was installed to transport slurry to two modified red tanks now serving as buffer tanks, from which it flows to the next processing stage. Relevant connecting pipelines were either pre-installed or reserved for flexible installation.

(4) Filter Press System Renovation

Originally, the plant operated with three chamber filter presses. In this renovation, one additional chamber filter press was installed (Model: XMZ600/2000). A new feed pump and a bottom discharge belt conveyor were also added.

The feed pump draws slurry from the bottom of the original leaching tanks and delivers it to the new filter press through a PE pipeline. The filtrate returns to the existing filtrate tank via gravity flow.

(5) Water Supply System Modification

The renovated system uses elevated water tanks for both fresh water and recycled return water, eliminating the need for additional supply pumps. The new supply pipelines use PE pipes, which are compatible with the abundantly available local pipe fittings and accessories.

With the meticulous planning and design by Xinhai Mining Design Institute, the CIL concentrator expansion project at the Malaysian gold mine was successfully completed in 2024. The processing capacity increased from 500 t/d to 800 t/d. The newly added core equipment and upgraded process systems are running stably, fully meeting the expected design targets. The project owner highly praised Xinhai Mining’s professional capabilities, engineering quality, and final project results.

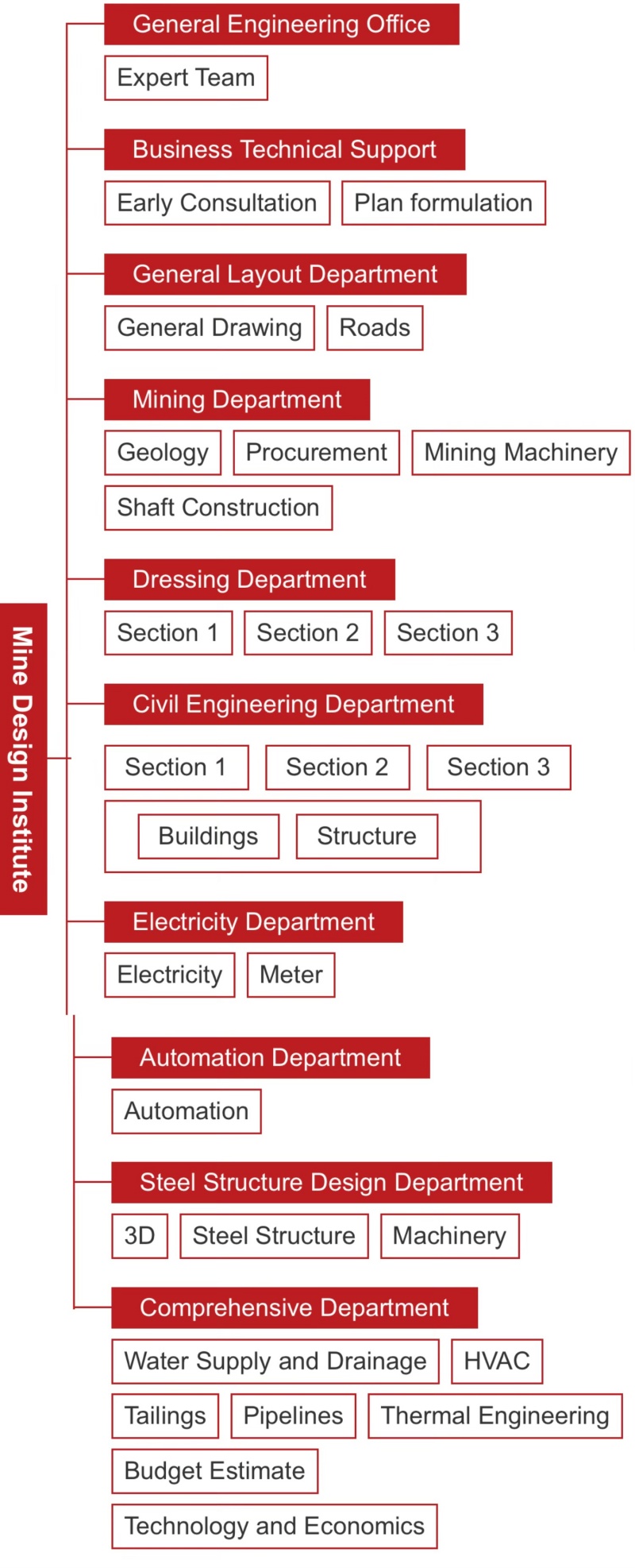

Xinhai Mining Design Institute holds Class B design qualifications in China’s metallurgical industry and is capable of designing in accordance with various national and international standards, including Chinese national standards, the Australian JORC Code, VALMIN Code, and Canadian NI 43-101 specifications.

The institute is staffed with over 80 experienced design professionals, covering 18 key disciplines including geology, mining engineering, mineral processing, mining machinery, water supply and drainage, piping, technical economics, general layout, civil engineering, and 3D design. This forms a complete, multidisciplinary team capable of delivering comprehensive engineering design solutions.

Xinhai Mining Design Institute has extensive experience in mineral processing plant renovation projects and has successfully completed multiple renovation designs across a wide range of minerals, including gold, copper, iron, lead, and zinc.

If you are planning to expand or upgrade your mineral processing plant, feel free to contact Xinhai Mining for professional support!