If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

As part of the broader development of gold processing plants in Africa, West Africa has emerged as a key region where CIL technology is widely adopted for both new builds and plant expansions. Places like Ghana, Mali, and Burkina Faso produce a lot of gold. Most gold here comes from medium or low-grade deposits. Workers get it out through big open-pit mines or underground ones. The ore can be tricky, and roads or power can be limited. So, getting steady gold out is tough. But the Carbon-in-Leach (CIL) way has proven reliable and flexible. It's now the go-to method in the area. This piece dives into CIL plants that fit West Africa well. We look at how they match the ore, the usual flow sheet, gear setup, build costs, and tips from real operations there.

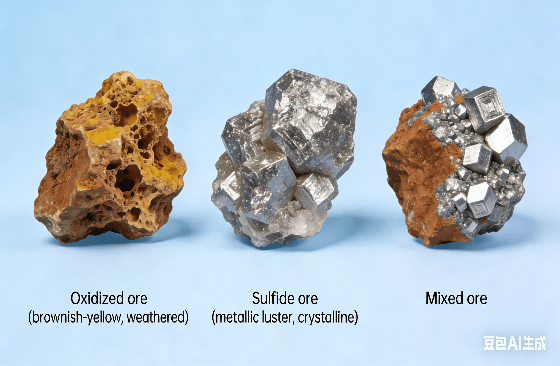

People sort gold ores in West Africa into three main kinds.

Oxide Ore: This type has gone through a lot of weathering. It leaches easily. Gold sits free or in tiny, spread-out bits.This type of oxide and transition ore is especially common in gold processing plants in Ghana, where large-scale, low-to-medium grade deposits dominate commercial gold production.

Sulfide Ore: Here, gold sticks with stuff like pyrite. You need careful grinding and longer leach times to get it out.

Transitional Ore: It's a blend of the two above. So, the setup has to handle both types.

In general, ores from this region have some common traits. Gold levels sit between 1–5 g/t. That's not super high, but big volumes make up for it. The gold particles are small, and many are very fine or ultra-fine. Most ores respond well to cyanide. But some have issues like lots of clay, carbon that grabs gold (preg-robbing), or too much fine sludge. These can mess with the circuit.

Because of this, you must keep grinding fine and steady. And you adjust the leach time or carbon amounts based on the ore that day. Unlike just gravity or heap leaching, CIL handles changes in ore better. It gives higher recovery overall, often 90-95%. Take the Essakane mine in Burkina Faso – they use CIL and get good, steady output from mixed ores.

Mines like Essakane or Taparko show how CIL shines with these variable ores.

From a tech side: CIL mixes leaching and adsorption at the same time. This brings steady recovery, around 90–95%. It's great for tiny gold bits and low grades. The method is old and tested. You can build plants from small 500 tpd up to big 5,000 tpd ones.

From running it day to day: The flow is ongoing. You can automate a lot. That means less need for top experts on site. Plus, you can add gravity or flotation easily if needed.

Why it fits West Africa especially: Roads and power aren't always great here. CIL is tough – it forgives mistakes and keeps going. Many want fast builds. Using EPC contracts with ready modules cuts the time a lot. For instance, the Houndé mine in Burkina Faso got built quickly with CIL and hit good production fast.

Similar CIP and CIL gold processing routes have also been successfully applied in Sudan, further demonstrating the reliability of carbon-based gold recovery across different African mining regions.

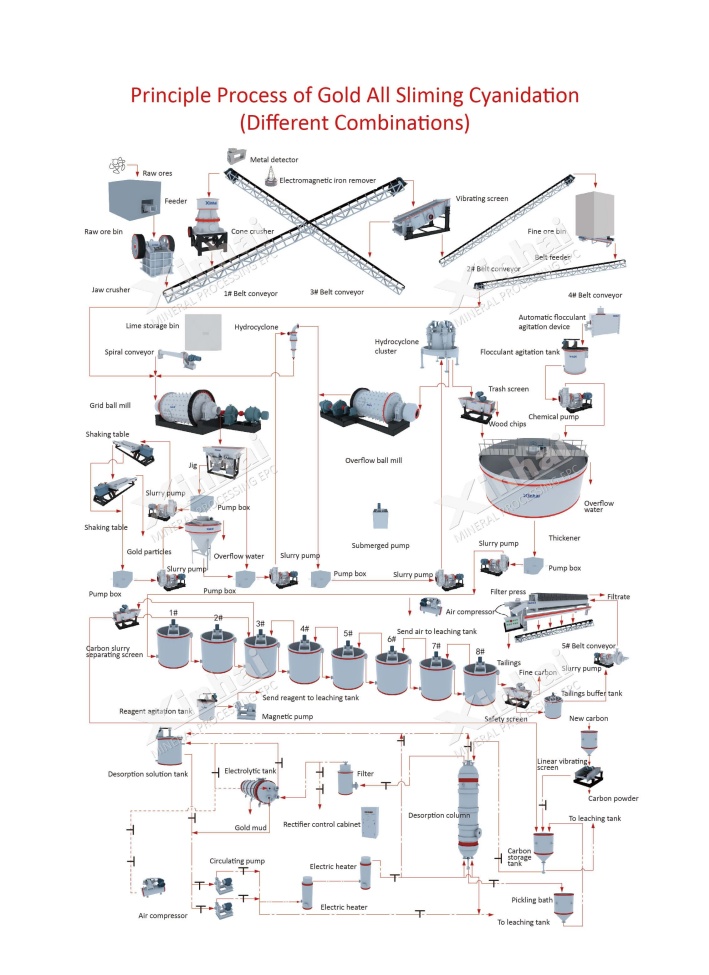

The full CIL path takes ore all the way to gold bars.

Crushing & Grinding: Usually two or three crushing steps. The ball mill is in a closed loop with classifiers. Aim for 80–90% passing 200 mesh. This frees the gold.

Pre-treatment (Optional): If coarse gold, add gravity like centrifuges or tables early. For clay-heavy ore, deslime or screen first.

CIL Leaching & Adsorption: The heart – 6–8 tanks in a row. Add cyanide and lime for pH. Carbon flows opposite way, grabbing gold as it dissolves.

These big tanks are key – agitation keeps everything mixed.

Elution, Electrowinning & Smelting: Strip loaded carbon in elution. Then electrowin to get sludge. Smelt to doré bars.

Tailings Disposal: Thicken leftovers. Store in a facility or dry stack. Follow local rules for the environment.

Many plants add gravity upfront. Like in Ghana's Tarkwa, they recover coarse gold first, boosting overall yield.

Pilot plants like this test the flow before a big build.

You group gear by jobs.

Core Modules: Crushing with jaw and cone crushers. Grinding – ball mill plus cyclone. Leaching tanks with agitators. Carbon screens, regen kiln. Elution column, electrowinning cells.

Key points in design: Mix well so carbon doesn't sink. Use tough materials against cyanide. Make the layout modular for growth later.

In West Africa, Pick ga ear that's easy to fix. Parts available nearby. Built for heat and dust. Many use diesel backups for power dips.

Flowcharts help see the full setup, from crush to smelt. In practice, selecting proven gold beneficiation equipment in Africa is critical to ensuring stable operation, low downtime, and consistent gold recovery in CIL plants.

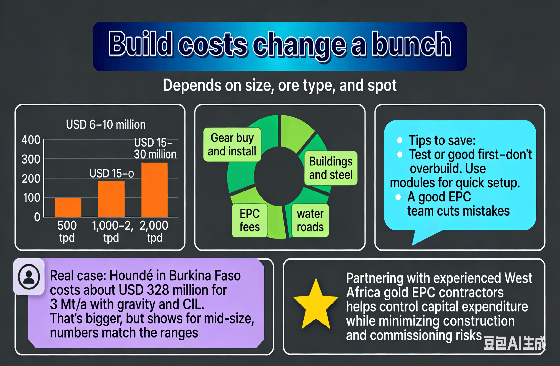

Build costs change a bunch. Depends on size, ore type, and spot. Roughly:

A 500 tpd plant might cost USD 6–10 million.

For 1,000–2,000 tpd, USD 15–30 million.

Big parts: Gear buy and install. Buildings and steel. EPC fees. Power, water, roads.

Tips to save: Test or good first – don't overbuild. Use modules for quick setup. A good EPC team cuts mistakes.

Real case: Houndé in Burkina Faso costs about USD 328 million for 3 Mt/a with gravity and CIL. That's bigger, but shows for mid-size, numbers match the ranges.

Partnering with experienced West Africa gold EPC contractors helps control capital expenditure while minimizing construction and commissioning risks.

Ore Variability: Ore changes day to day. Fix: Adjust reagents and grind on the fly.

High Slimes Impacting Leach Efficiency: Fine mud slows things. Add a deslime step or gravity to grab free gold early.

Activated Carbon Wear and Loss: Carbon breaks or leaks. Better screens and a regen kiln help.

Unstable Power and Water Supply: The Grid fails often. Use diesel mix and big water tanks.

Many mines add solar now, like some in Mali, to steady power. And for security issues in parts of Burkina or Mali, plants build strong fences and work with locals. It's not easy, but solutions work when planned right.

Every project is different. Good CIL starts with knowing your ore deep. We can help with tests, design, gear, to full EPC.By working with professional teams offering EPC and EPCM services in West Africa, mine owners can accelerate project delivery and achieve reliable long-term performance from their CIL plants.

Planning a West Africa gold job? Reach out. We'll talk custom setup based on your ore and site. It could save time and money in the long run.