If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Zimbabwe's gold mining is a vital economic contributor, but requires advanced processing solutions to unlock its full potential. The need for specialized Zimbabwe gold processing plants arises from the nation's complex geology with diverse ore types and a mining sector ranging from large-scale to artisanal operations. Therefore, a successful plant must adapt to various ore types and local infrastructure.

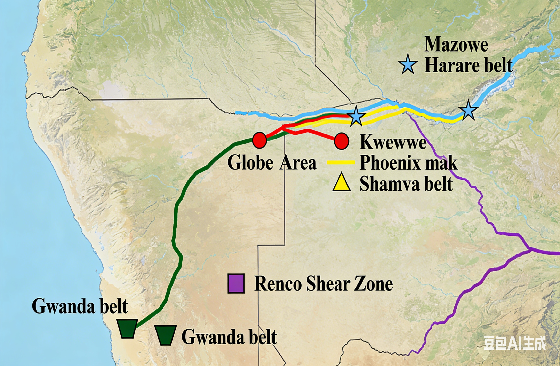

Pretty much all of Zimbabwe’s gold sits inside those ancient greenstone belts scattered across the Zimbabwe Craton – the kind of geology that makes prospectors drool. Down south you’ve got the crazy-rich Gwanda belt, up north the old-school Mazowe (sometimes still called the Harare) belt that’s been pumped for over a century, and right in the middle the Kwekwe area where legends like Globe and Phoenix made history. Then there’s the Shamva belt and the sneaky Renco Shear Zone further south. Point is, every single one of these spots throws different rocks at you, so anyone dreaming up Zimbabwe gold processing plants better study the local ground first, because what works in Gwanda might totally flop in Shamva.

Here’s the headache: close to the surface, you often get nice, friendly oxidized ore that practically gives up its gold with a smile. Dig deep, and suddenly you’re wrestling nasty sulfide stuff where the gold is trapped inside pyrite or arsenopyrite like it’s in prison – way harder (and pricier) to free. Throw in the fact that half the country’s gold comes from small-scale and artisanal miners, plus the power grid that loves taking random holidays, and you see why cookie-cutter plants just don’t cut it. Any serious Zimbabwe gold processing plant has to be tough, adaptable, and ready to run even when the lights go ou,t or the ore decides to be difficult that day.

This ore type results from the weathering of primary sulphide bodies near the surface. It is typically softer, with gold that is readily leachable using cyanide. The standard and most cost-effective processing route for free-milling oxidized ore is a Carbon-in-Leach (CIL) plant. In a well-designed circuit, gold recovery rates for clean oxidized ores can reliably range from 85% to 92%, making it a primary target for many operations.

Down in the primary stuff, the gold is usually stuck tight inside sulfide minerals – mostly pyrite, sometimes arsenopyrite. If you just throw cyanide straight at this rock, you’ll be lucky to pull out 20-30%. The solution literally can’t reach the tiny gold specks hiding in there.

So the only sensible way is to do it in two clear steps: first, knock out a nice rich concentrate with flotation, then leach only that small concentrate. That’s why pretty much every proper plant ends up running a Flotation + CIL combo. You shrink the amount of material that has to go through the expensive cyanide part from, say, a hundred tonnes down to maybe five or six, and suddenly the whole operation stops bleeding cash on complex ores.

Now, some Zimbabwean material is downright stubborn – we’re talking proper refractory sulfide ores where the gold is scattered in super-fine particles throughout the pyrite lattice. Even after you’ve floated a beautiful concentrate, the gold still refuses to come out and play.

For the ones that aren’t completely evil (the “moderately refractory” crowd), a trick that actually works here in Zim-style is to slap a couple of cheap pre-oxidation tanks in front of the CIL. You basically just pump air hard through the concentrate, maybe chuck in a bit of peroxide or whatever mild oxidant you can get hold of, and you bust open enough of the sulfide cage to let the cyanide do its job later. Not fancy, not perfect, but it gets the recovery up without needing a full-blown roaster or pressure oxidation setup that costs an arm and a leg.

For ores containing a significant portion of coarse, liberated free gold, incorporating a gravity concentration circuit at the head of the flow sheet is highly advantageous. Gravity units like centrifugal concentrators or shaking tables can recover 20-40% of the gold upfront as a high-grade concentrate. This reduces cyanide consumption and lowers the gold load on the downstream CIL tanks, leading to lower operating costs (OPEX) and often higher overall recovery.

This is the definitive flow sheet for processing sulfide gold ores in Zimbabwe. The flotation circuit separates valuable sulfide minerals (and the gold they carry) from waste gangue. The resulting low-mass, high-grade concentrate is then leached in a dedicated CIL circuit for complex ores. This route is more capital-intensive (CAPEX) but is indispensable for achieving economic recovery rates from sulphide deposits, which can exceed 85-90% on the concentrate.

For mines dealing exclusively with soft, free-milling oxidized ore, a standalone CIL plant offers the most straightforward and lowest capital cost solution. This route involves grinding the ore to a fine size and directly introducing it into a series of leaching and adsorption tanks with activated carbon. It is a proven, robust technology ideal for many small to medium-scale operations in Zimbabwe targeting near-surface oxide resources.

Gold Mining Equipment in Zimbabwe, including:

Crushers: Jaw and cone crushers for size reduction.

Grinding Mills: Ball mills or SAG mills for liberation.

Gravity Concentrators: For pre-concentration of free gold.

Flotation Cells: Essential for sulphide ore concentration.

CIL Tanks & Agitators: The heart of the leaching process.

Elution & Electrowinning Unit: For final gold recovery from carbon.

Capital costs are highly scale-dependent. For a conventional gold processing plant in Zimbabwe, estimated CAPEX ranges are:

300 TPD Plant: ~$4 million - $8 million USD

500 TPD Plant: ~$6 million - $12 million USD

1000 TPD Plant: ~$10 million - $20 million USD

These ranges cover basic engineering, equipment, construction, and commissioning, but can vary widely based on ore complexity (need for flotation, etc.), site conditions, and the level of local infrastructure.

Major ongoing costs include:

Cyanide: A key reagent cost, influenced by ore type and gold grade.

Power: A significant variable, especially given grid instability; fuel for backup generators adds cost.

Grinding Media & Liners: Regular consumables for mill operations.

Labor & Maintenance: Skilled personnel are crucial for optimal operation.

To control costs and support local industry, several components offer local procurement opportunities in Zimbabwe. These include structural steel, tanks, piping, electrical works, and basic civil construction. However, specialized core processing equipment like high-efficiency ball mills, flotation cells, advanced crushers, and elution columns typically need to be imported from international suppliers with proven technology and reliability. Partnering with an experienced engineering firm that understands this supply chain dynamic is key to a cost-effective and successful project.

One of the representative gold processing projects in Zimbabwe is the 700 t/d Gold Mineral Processing Plant, delivered by Xinhai Mining under an EPC+M+O model. The raw ore had a high grade of 6 g/t, and to ensure both high recovery and safe, stable operation, Xinhai performed comprehensive planning and design based on the client’s ore characteristics and production targets.

The plant adopted a robust and efficient flow sheet:

One-stage grinding → Two-stage closed-circuit classification → Gravity concentration → Cyanidation → Desorption electrolysis → Smelting → Tailings dewatering

Gravity concentration was added to the grinding circuit to recover free gold early and avoid losses during leaching.

The high-grade ore required efficient grinding and controlled cyanidation to maximize extraction.

The project emphasized environmental protection, workplace safety, and a well-organized layout to shorten the construction period.

Xinhai completed detailed design, construction, equipment supply, installation, and commissioning for the full process—from crushing and grinding to gravity concentration, CIL leaching, filtration, carbon regeneration, and smelting.

The plant achieved excellent technological and economic outcomes, delivering stable operation, strong recovery, and reduced operating costs.

This project stands as a benchmark for medium-scale gold processing plant construction in Zimbabwe and demonstrates how tailored EPCM+O services can ensure smooth, successful project delivery.

Another gold mining project in Tanzania has also yielded satisfactory results.

Planning a new gold processing plant in Zimbabwe?

Xinhai Mining provides:

√ Custom metallurgical testing

√ Flow-sheet design

√ Full EPCM+O delivery

√ Equipment manufacturing & installation

√ 300–2000 t/d turnkey gold processing plants

Contact us to receive a free Zimbabwe-specific CIL/CIP design and cost estimate within 24 hours. If you would like to learn about gold processing plants in Africa: a complete guide, please click the link.