If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

In mineral processing, miners separate valuable ore from useless rock, called gangue. A key step, often ignored, is splitting solids from liquids. Thickening and dewatering equipment play a huge role in modern mines. They help save water for reuse, shrink the pile of waste (called tailings), and boost efficiency while meeting eco-friendly rules. This article dives into the main tools used for thickening and dewatering in mining plants, explaining how they help with water recovery and tailings management.

Thickening boosts the solid content in a watery mix, known as slurry, by letting solids settle with gravity. The goal? Create a thicker underflow and clear water on top. This process is vital for a few reasons:

It grabs clean water to reuse in the plant.

It cuts down the slurry volume, easing the load on dewatering tools and saving money.

It preps a thick, pumpable slurry for moving to waste storage areas.

How well thickening works depends on things like slurry thickness, particle size, shape, and chemicals called flocculants that help solids clump. The equipment’s design matters too. Honestly, getting this right feels like a bit of an art sometimes!

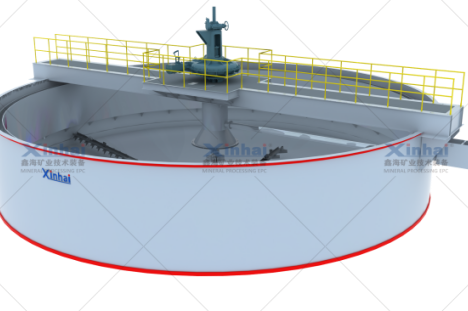

Different thickeners suit different jobs in mineral processing. Here’s a rundown of the main ones:

These modern machines have a steep, sloped bottom to speed up settling. They hold a lot, have auto-lifting rakes to avoid jams, and save energy. You’ll see them in gold, copper, lead-zinc, or graphite plants. For example, a gold mine in Nevada might use these to process 500t/d, recovering 80% of water for reuse.

With a tall, steep cone, this thickener squeezes solids tightly, creating a paste-like underflow. It’s great for tailings with fine particles or high clay, like in an Australian iron ore mine dealing with sticky red mud. The paste cuts water in tailings by up to 60%, making storage safer.

These have a drive that circles the tank’s edge, perfect for huge setups like tailings ponds. A South African diamond mine might use one to handle 10,000 tons of slurry daily, pulling out water for reuse in processing.

High-efficiency thickeners and deep cone thickeners shine in eco-conscious projects. They save space and work fast, which is why green mining loves them.

Thickening makes slurry denser, but dewatering goes further, pulling out most leftover water to make a damp or nearly dry solid cake. This step matters because it:

Cuts costs for hauling and storing waste.

Makes tailings dams safer by using stable, stackable solids instead of watery slurry.

Supports dry stacking, a greener way to manage waste.

Preps mineral concentrates for shipping and selling.

For instance, a Chilean copper mine might dewater concentrates to hit a 10% moisture target, making transport cheaper and safer.

Here’s a look at the main dewatering tools used in mines:

A filter press uses high pressure to push water through cloths, trapping solids in chambers to form tight cakes. It’s top-notch for low moisture, like 8-12% in gold concentrates. Modern automated presses, used in places like Peru’s silver mines, crank out 200 tons of dry cake daily.

These use suction to pull water through a cloth. Disc and drum filters run non-stop, great for high volumes, like coal or iron concentrates. A West Virginia coal plant might process 1,000 tons daily with a disc filter, hitting 15% moisture.

This setup mixes slurry with flocculants, drains water by gravity, then squeezes it between belts. It’s affordable and easy to maintain. A phosphate mine in Morocco could use it to dewater 500 tons of tailings daily, keeping costs low.

These use vibration to drain water from coarse stuff like sand or crushed ore. They’re often a first step, like in a Canadian gravel pit removing 70% of water from 300 tons of sand per hour.

Centrifuges spin fast to separate solids and liquids. They’re great for tricky jobs, like dewatering fine coal in an Appalachian mine, hitting 10% moisture in 50 tons daily.

Choosing the right dewatering tool depends on the material, moisture goals, and how much you need to process. It’s not one-size-fits-all!

| Aspect | Thickening | Dewatering |

|---|---|---|

| Main Purpose | Increase solid concentration | Remove remaining moisture |

| Typical Output | Underflow slurry (thickened pulp) | Nearly dry solid cake |

| Common Equipment | Mining thickener (High-Efficiency, Deep Cone) | Filter press, vacuum filter, dewatering screen |

| Water Recovery Rate | 60–80% | 85–95% |

Picking the best thickening and dewatering equipment needs careful thought. Here’s what to consider:

Ore Type: Are particles fine or coarse? High clay, like in some African bauxite mines, might need deep cone thickeners.

Water Recovery Goals: Need super-clear water or just low moisture? A filter press might be best for 8% moisture in copper concentrates.

Plant Size and Automation: A big mine, like one processing 20,000 tons daily, needs high-capacity, automated gear. Smaller setups might go for simpler conventional thickeners.

Local Rules: Some places, like Chile, push for dry stacking to save water, so dewatering screens or presses are key.

Companies like Xinhai Mining offer tailored solutions. They blend equipment, process design, and automation to make plants efficient and green. For example, a test in a Brazilian iron mine might show a deep cone thickener cuts tailings water by 65%, saving millions in dam costs.

Thickening and dewatering equipment aren’t just tools—they’re game-changers for sustainable mining. They save water, make tailings safer, and cut costs. Picking the right gear, like a high-efficiency thickener or a filter press, can transform a plant’s performance. It’s not just about profit; it’s about mining smarter for the planet. Gotta say, it’s pretty satisfying to see a mine run lean and green!

Thickening ups the solid content in slurry, making it thicker but still pumpable. It pulls out some water. Dewatering goes further, squeezing out most water to leave a damp or dry cake ready for handling or shipping.

Deep cone thickeners make super-thick underflow, like paste, which is great for backfill or stable tailings storage. They cut water content a ton, like 60% in some gold mines, making waste safer and dams sturdier.

Look at your ore—fine or coarse? Check moisture goals, like 10% for concentrates. Consider plant size and budget. Local laws matter too. Running tests, like a pilot in an Australian nickel mine, helps nail the best pick.