If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Gold processing plants across the globe wrestle with balancing efficiency, cost, and eco-friendly practices. Tougher environmental laws, soaring water prices, and the push to squeeze out every bit of gold make solid-liquid separation a big deal. Thickeners in Gold Processing Plants stand at the heart of this challenge. They thicken slurries, recycle water, and manage waste, becoming a must-have for modern gold mines.

In gold mining, splitting solids from liquids shapes every step—from prepping ore for leaching to handling tailings. A solid thickener ramps up gold recovery, slashes water use, and lifts the plant’s overall game. Honestly, it’s like the unsung hero of the operation!

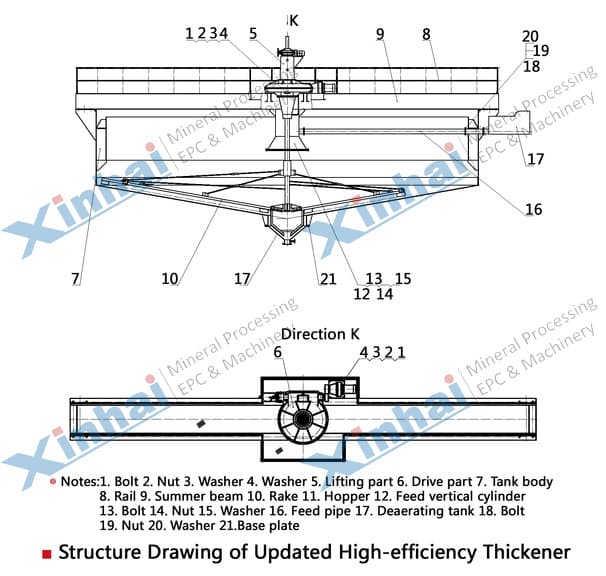

Thickeners use gravity to do their magic. Slurry flows in, heavy particles drop to the bottom, and clear water floats up. Here’s how the main parts team up:

Feedwell: Spreads slurry smoothly to avoid a messy swirl, helping solids settle fast.

Tank body: A wide, round basin where solids sink as slurry creeps to the center.

Rake system: Slow-turning arms nudge settled solids to the bottom’s core for easy removal.

Underflow discharge: Pumps out thick slurry for the next steps in processing.

Overflow launder: Gathers clean water at the top, ready to loop back into the plant.

Old-school thickeners get the job done but hog space. Modern high-efficiency ones, with tilted plates and smarter feedwells, speed things up. They handle more slurry in a smaller spot—perfect for packed or space-tight mines.

Thickeners slot into key spots in gold processing. Here’s the flow:

Crushing → Grinding → Leaching/Flotation → Thickening → Filtration → Tailings

Post-leaching/tailings thickening: After cyanide leaching, thickeners pack leftover slurry into dense tailings. This makes storage simpler and sends water back to leaching—a lifesaver in dry areas.

Pre-leaching concentration: Thin slurry (30–40% solids) gets thickened to 50–60% solids. This makes leaching quicker and more effective, boosting gold recovery.

Concentrate thickening: In flotation plants, thickeners condense gold-rich froth. This eases the strain on filters and saves power.

By reusing water and streamlining slurry, thickeners tighten the process. They cut waste and keep costs down.

A top-notch thickener changes the game for gold mines. Here’s why:

Better leaching: Thicker slurries (50–60% solids) let gold and chemicals mix better. This can lift extraction rates by up to 5%. That’s a big win for profits!

More water reuse: Pulling 80–90% of water from slurry slashes the need for fresh water. A medium-sized mine might save 15 million cubic meters a year. That’s serious cash saved.

Stable tailings: Thickened tailings (60–70% solids) are simpler to move and store. They cut pond upkeep costs by 40% and lower the risk of spills.

Take this real case: A Nevada gold mine switched to a high-efficiency thickener. Underflow solids jumped from 45% to 62%. Leaching time dropped by 20%, water reuse climbed 30%, and gold recovery rose 7%. That added $1.2 million to their yearly haul. Not too shabby, right?

Picking the right thickener depends on the slurry and your goals. Here’s a breakdown:

| Type | Features | Application | Advantages |

|---|---|---|---|

| Conventional | Big diameter, basic rakes | Simple dewatering, thin slurries | Cheap, easy to fix |

| High-Efficiency | Tilted plates, improved feedwells | Gold tailings, concentrate thickening | 30% more capacity, 50% less space |

| Deep Cone | Steep cone, high pressure | Dry stacking, thick underflow | Up to 75% solids, tiny storage needs |

Small mines often stick with conventional thickeners to save money. Bigger operations, especially in water-scarce spots, lean toward high-efficiency models. For dry stacking—where no ponds are used—deep cone thickeners are the go-to.

To get the most out of Thickeners in Gold Processing Plants, focus on these:

Feed properties: Fine gold particles need flocculants to clump up and settle slowly. Lab tests help nail the setup before diving in.

Feedwell design: A good feedwell calms the slurry’s flow. This prevents turbulence and keeps settling steady. Newer designs use baffles for smoother results.

Rake operation: Rakes turn slowly—about 0.5 to 2 rpm. This keeps solids from stirring up but avoids clogging. Watching torque spots problems early.

Automation: Sensors check slurry density and water clarity. They tweak flocculant doses or rake speed on the fly. This cuts mistakes and keeps things running smoothly.

Thickeners bring wins for both the planet and the wallet. Here’s how:

Environmental: Reusing water protects local rivers and lakes. Thickened tailings shrink pond size by 60%. This lowers leak risks and helps meet “zero discharge” rules.

Economic: Recycling water saves $0.50 to $2 per cubic meter. Thicker underflow cuts pumping costs and filter time. For a mid-sized mine, that’s $500,000 to $1 million saved yearly.

Compliance: Thickeners keep metal and turbidity levels within legal limits. This avoids hefty fines and keeps the mine’s reputation solid.

From my perspective, it’s pretty impressive how one piece of equipment can tackle so many issues at once—green and cost-saving!

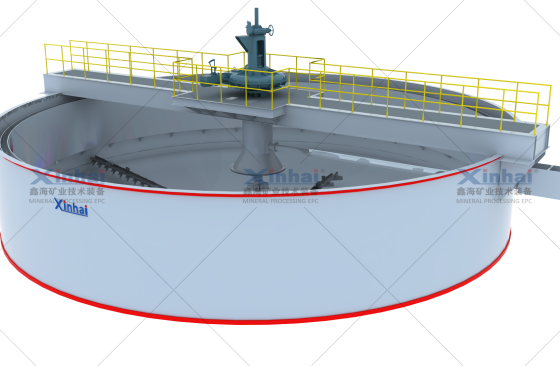

Xinhai builds Thickeners in Gold Processing Plants tailored to tough challenges:

High-Efficiency Models: Process 500 m³/h while using 30% less space. They come with tilted plates and self-cleaning feedwells for top performance.

Deep Cone Thickeners: Deliver 70–75% solids for dry stacking, ideal for sensitive areas with strict rules.

Durability: Rubber-lined tanks and rakes stand up to abrasive tailings. They last 2–3 years longer than standard models.

Smart Controls: Sensors fine-tune settings in real time. This keeps slurry density just right.

Real-world example: A West African gold plant switched to Xinhai’s thickener. Underflow concentration climbed 35% (from 40% to 54%). Water use dropped by 25%, and leaching efficiency rose 6%. That’s a solid upgrade!

Xinhai’s EPC+M+O service handles everything—design, setup, training, and upkeep. It’s a full package to keep things running smoothly.

Thickeners in Gold Processing Plant don’t grab headlines, but they’re game-changers. They boost gold recovery, slash water costs, and keep mines on the right side of regulations. Whether it’s concentrating ore, reusing water, or managing tailings, a good thickener turns problems into possibilities.

Want to level up your gold processing? Check out Xinhai’s cutting-edge thickener solutions. Reach out for custom designs and EPC+M+O services to fit your mine’s needs.