If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Mining jobs kick up huge piles of tailings. These are the leftover bits after pulling out the good minerals. They often end up in ponds or big dams. This can cause real headaches, like dirty water, dam breaks, or wrecked land. Getting the water out of tailings is key. It helps cut those dangers and keeps mining a bit greener.

Dewatering shrinks the water in tailings. So, they’re simpler to move, haul, and stash away. Plus, it lets you grab back water for reuse. That’s a big deal in dry spots where water’s hard to come by. Rules on the environment are getting tougher. Costs to run things are climbing too. So, picking the top thickener for tailings dewatering is smart business for mining outfits.

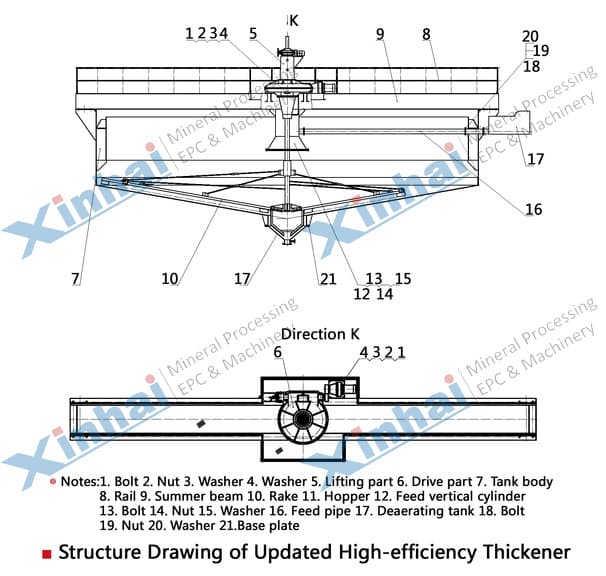

Thickeners play a big part in handling tailings. They pull solid bits together from the sloppy mix. This happens through settling. Clear water spills over the top. The thick stuff at the bottom gets pumped out for more work or dumping.

Old-school thickeners get the job done. But they have downsides. Like, they’re not super speedy. They guzzle energy. And they take up tons of space. Pressure from green groups is growing. Tailings handling is a tough nut for processing plants. Old thickeners suck up power, work slow, and cost a bundle to run. That’s why folks came up with better ones. Like high-rate thickeners. They do better and save cash. For example, at a copper mine in Kazakhstan, switching to a high-rate model cut water loss to the tailings dam by 11%. Underflow density jumped from 54% to 57% solids. That meant less fresh water needed overall.

The top thickener for tailings dewatering needs a few standout traits.

First, smart settling setup. The high-rate thickener uses slanted plates for settling. This cuts the drop path from 3 meters down to 0.5 meters. Particles sink way faster.

Next, a sharp flocculation setup. It has a high-rate system. This mixes a pipe blender with sound wave spread tech. It makes flocculant work much better.

Then, better sludge squeeze. The bottom has a deep cone or strong rake setup. This presses the settled gunk harder.

Also, thick underflow. The bottom mix hits 50%–70% solids. That trims costs for later steps like filtering or stacking dry.

Finally, smart controls. The high-rate thickener has live tracking and tweak tools. It uses density gauges, cloudiness meters, twist sensors, and more. These keep things running smooth.

All these bits team up. They boost speed and trim running bills. Honestly, it’s neat how a few tweaks make such a difference in daily ops.

Grabbing water back is huge in tailings care. Top thickeners make big gains here.

The fast settling setup gets overflow water super clear. Suspended solids drop below 50 mg/L. You can pump it right back into mineral work. This cuts new water use by recycling. It saves water. And it means less pull from outside sources. That’s gold in dry mine areas.

On top, high underflow density—up to 70%—shrinks liquid waste. Less needs extra cleanup or storage. For instance, at a Chilean copper-moly mine up at 1700 meters high, they recycle seawater piped in from 143 km away. A high-rate thickener boosted their water loop, slashing fresh intake costs in a water-short spot.

New thickener tricks set them apart from old ones.

One is easy-build modules. The high-rate thickener uses prefab parts. Like the tank, drive setup, and controls. Compared to old installs, it starts up about 50 days sooner.

Another is big-size builds. It goes for wide deep cones. Diameters hit 30 to 100 meters. This grows the settling space 3 to 10 times over.

Plus, brainy AI watch. Smart codes guess fixes ahead. They tweak the settling plan on the fly. They adjust flocculant adds based on past runs.

These steps mean steadier work. Less stop time. Fewer fix jobs. At Collahuasi Mine in Chile, they added a 22-meter deep cone thickener. It handled tough tailings better. Water recovery jumped, and they cut floc use by mixing ultrasonic tech into the floc system.

Putting in a top thickener pays off in real ways.

Power savings first. The high-rate thickener uses easy-turn drive tech. It has a light rake frame and speed-shift motor. Drive power drops 30%–50%.

Fix costs go down too. Rake teeth use tough tungsten carbide. Wear rate falls 70%. So, fixes happen less. IoT gadgets watch bearing shakes and oil states live. They spot issues early. This cuts fix bills by 40%.

Chemical use shrinks. A smart add system pairs with good mix tech. It saves 20% on reagents. Lower spend on chems.

These wins add up. They lower the full own cost over years. Man, seeing those numbers drop feels like a win after all the setup hassle.

Picking the right thickener means weighing tech and money sides.

1. Handling load. Make sure it matches now and later output. A single Φ60m thickener takes up to 5,000 t/h. No need for multiple units syncing up.

2. Space limits. In tight spots or full ponds, small designs win big.

3. Water clean needs. Check overflow clearness against recycle rules.

4. Auto help. In far-off or worker-short places, smart systems cut hands-on work.

5. Stuff traits. Particle spread sways floc pick and sink ways. Key for setup.

6. Money check. Weigh saves on power, chems, fixes against up-front cash.

Take Las Cenizas Mine in Chile. They picked a 17m high-rate thickener for space crunch. It fit their porphyry copper tailings. Processing sped up 20%. Water backhaul rose 18%. And they dodged extra dam builds.

Green ways are key to mining plans now. Coming shifts will hit:

Better tie-ins with dry stack steps.

Sharper AI tweak tools.

Nice-to-nature flocculants.

Growth in plug-and-play mobile units. For small or short jobs.

Real spots show this in action. Like at Delta plant in Chile. They added a 12m high-rate unit. It meshed with paste tailings. Dewatering hit 65% solids. Water reuse climbed 22%. And community gripes dropped since less pond spill risk.

A porphyry copper mine in Chile swapped four φ30m old thickeners for one φ45m high-rate thickener. After the switch, handling rose 30%. Water return jumped 25%. Floc use fell 45%. Yearly power bill dropped $160,000.

A magnetite mine in Anshan went from wet dump to dry stacking. They used hydrocyclone → efficient thickener → deep cone thickener → filter press. Moisture cut 53%. Haul costs down 40%. Power per ton fell 27%.

These stories show how grabbing new stuff like high-rate thickeners fixes green woes. It sparks better runs too. Makes them the real best thickener for tailings dewatering right now. From my view, it’s about time mining caught up—feels good seeing real change on the ground.