If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

With rising mineral processing costs, optimizing the dewatering section has become key to enhancing the overall efficiency of a processing plant. How can moisture content in the concentrate be controlled within an ideal range? How can tailings transport costs be reduced and water reuse rates increased? The Xinhai High-Efficiency Thickener is the crucial equipment for achieving these cost reduction and efficiency improvement goals!

In the entire mineral processing flowsheet, thickeners are often viewed as "stable but unremarkable" units. However, practical production experience shows that their performance directly impacts two core costs: water resources and energy consumption. Common issues with traditional thickeners – such as cloudy overflow, low underflow density, frequent clogging, and insufficient processing capacity – not only lead to low water recovery rates and increased fresh water costs but also result in soaring energy consumption in subsequent transport and filtration stages. Drawing on over 30 years of field experience, Xinhai Mining Manufacturing has developed the High-Efficiency Thickener, designed to unlock hidden profits from this dewatering stage and promote the refinement and intelligent upgrading of mineral processing operations.

The Xinhai High-Efficiency Thickener is not merely a simple structural modification but a systematic solution based on fluid dynamics, sedimentation theory, and materials science. Its core innovations are embodied in the following seven aspects:

The traditional internal overflow weir significantly reduces the effective settling area. Xinhai innovatively employs a peripheral overflow weir design, allowing the entire bottom area of the tank to function as an effective settling zone, increasing the settling area by approximately 15%-30%. This not only directly enhances processing capacity but also provides sufficient settling time for fine particles, fundamentally resolving siltation and blockage issues.

Air bubbles entrained in the feed slurry can attach to solid particles, creating a "parachute effect" that severely hinders settlement. Xinhai incorporates a dedicated deaeration tank within the feed system. Through its unique flow path design, it effectively separates and removes entrained air before the slurry enters the settling zone, ensuring solid particles can settle freely under pure gravity, significantly increasing settling rates and overflow clarity.

Replacing the traditional horizontal feed direction with an inclined feed, combined with a feed pipe submerged below the liquid level, achieves two main objectives: Firstly, it fundamentally eliminates the disruption of the settled bed caused by vertical impact ("boiling"). Secondly, it effectively prevents air entrainment during feeding, creating a stable environment for subsequent sedimentation.

By lowering the feed well and equipping it with a diffuser-type feed launder, the high-velocity incoming slurry is cushioned and spread, effectively dissipating its kinetic energy. The slurry enters the settling zone evenly and smoothly, preventing "short-circuiting" and turbulence caused by residual pressure, making the entire settling process more orderly and efficient.

While maintaining the peripheral overflow weir, an internal peripheral weir is added, guiding the clarified water along a defined path. This design effectively lengthens the water flow path, prevents "short-circuiting" of clarified water, ensures the vast majority of solid particles have ample opportunity to settle, and greatly improves the utilization efficiency of the settling zone.

Upgrading the smooth overflow weir to a precisely engineered serrated (or V-notch) weir. This improvement compensates for minor installation or operational imperfections in levelness, avoiding localized suction effects that can draw solids into the overflow, thereby ensuring overall uniform effluent quality and low turbidity.

A proprietary stillening (or energy dissipation) device is installed in the upper part of the settling zone. It further slows down and evenly distributes the velocity of the upward current, providing a final opportunity for the finest particles and flocs to settle. This serves as the last robust barrier ensuring consistently clear and stable overflow water quality.

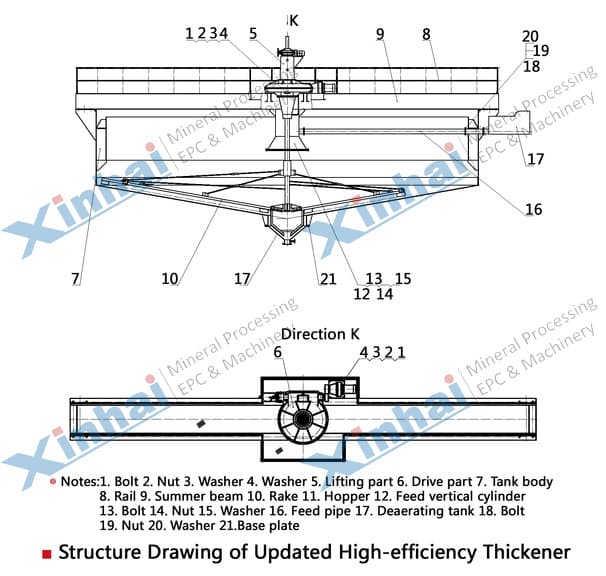

The Xinhai High-Efficiency Thickener maintains the classic structure comprising a circular thickening tank and a mechanical rake mechanism, but the internal flow dynamics and separation efficiency have undergone a qualitative leap.

The working process is as follows:

Pre-treated Feed: The slurry, after deaeration and stabilization, enters the thickener tank smoothly.

Gravity Sedimentation: In the quiescent settling environment, solid particles settle freely under gravity, forming a thickened bed. The upper clear water zone, protected by the stillening device, forms clarified water.

Sludge Raking and Collection: The concentrated sludge settled at the bottom is continuously and slowly raked by the robust and efficient rake mechanism towards the central discharge port at the tank bottom.

Solid-Liquid Separation: The high-density underflow is discharged by a pump for the next process stage; the clear overflow water uniformly flows over the serrated weir and returns to the process circuit for reuse.

The entire system can achieve automated control, automatically adjusting rake speed and flocculant dosage based on feed rate and density, enabling unattended operation and optimal performance.

This equipment covers a wide processing capacity range of 5 to 1400 t/d and is suitable for concentrate thickening and tailings dewatering in large-scale concentrators.

Core Value Delivered to Customers:

Significant Economic Benefits:

Water Savings: Drastically reduced overflow turbidity (can be below 200 ppm), increasing water recovery rates to over 90%, directly saving fresh water costs and wastewater treatment expenses.

Energy Savings: Higher underflow density (density can be increased by 15%-30%) significantly reduces energy consumption of subsequent transport pumps and filtration equipment.

Reduced Maintenance: The clog-resistant design reduces cleaning and maintenance efforts by at least 70%, lowering labor and downtime costs.

Win-Win Production and Environmental Benefits:

Process Stability: High operational stability ensures smooth operation of the entire plant flow sheet.

Improved Recovery: Effectively reduces metal loss in the overflow.

Environmental Compliance: Clear overflow meets requirements for recycle/reuse and environmental discharge standards.

Based on actual data from our numerous retrofit projects, customers typically recover the entire investment through cost savings within 1 to 2 processing seasons, demonstrating a clear Return on Investment.

In an increasingly competitive market environment, achieving internal potential through technological transformation is essential for the sustainable development of mineral processing enterprises. The Xinhai High-Efficiency Thickener, with its seven practically proven core technologies, offers you not just a piece of equipment, but a reliable dewatering solution and a partner committed to enhancing your core competitiveness and achieving green, low-carbon development.

We understand that the ore characteristics, flow sheet layout, and pain points of each processing plant are unique. Therefore, we offer "one-on-one" technical diagnostics and customized solution services.

If you wish to:

Obtain a specific technical proposal and benefit analysis report tailored to your concentrator;

Access detailed technical information on more success stories;

Schedule an on-site or online technical exchange with our engineers.

Please feel free to contact Xinhai via our website customer service or WhatsApp. Our technical team is ready to serve you. Let Xinhai's expertise become the solid technical foundation on your path to cost reduction and efficiency gain.