If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Gold extraction plays a pivotal role in the mining industry, with several processing methods available depending on the ore characteristics. Modern gold beneficiation methods primarily include gravity separation, flotation, and cyanidation techniques.

Choosing the optimal extraction method is crucial to maximizing recovery rates, minimizing costs, and reducing environmental impact. From the examples and comparisons, we can conclude that neither flotation nor cyanidation gold extraction process is a perfect gold extraction process for all mines. When selecting the gold extraction process, we must first conduct a mineral processing test on the mine, and select the most suitable process according to the experimental results and actual conditions.

Among the most widely used techniques today are the flotation method and the carbon-in-leach (CIL) process. This article explores the topic of “gold flotation vs gold CIL,” comparing both in terms of efficiency, applicability, and environmental footprint.

Gold flotation is a chemical method for separating hydrophobic materials from hydrophilic ones. It is particularly suitable for ores where gold is closely associated with sulfide minerals. Flotation gold extraction process is not only simple in process, but also has a relatively simple requirement in infrastructure and equipment.

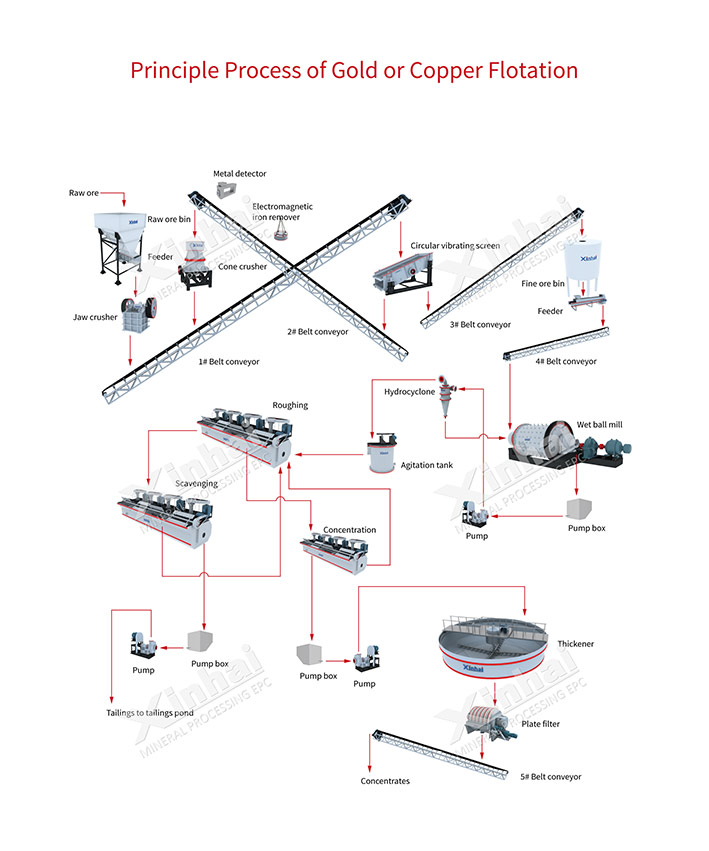

Gold flotation plants use conventional flotation machines such as mechanical cells and flotation columns. These setups typically include crushers, ball mills, flotation tanks, and thickeners. There is not much difference between single flotation process equipment and other metal ore flotation equipment.

Various and complex agents need to be used based on a proportion in flotation gold extraction process, like the foaming agent, inhibitor, activator, collector and other agents. These reagents help separate valuable minerals from waste by altering their surface properties to promote attachment to air bubbles.

The primary advantages of flotation include simplicity of equipment and lower capital investment. Therefore, in terms of cost, gold cyanidation is much higher than flotation. Flotation is particularly effective for gold ores that contain sulfide minerals or quartz veins with coarse and uneven distribution.

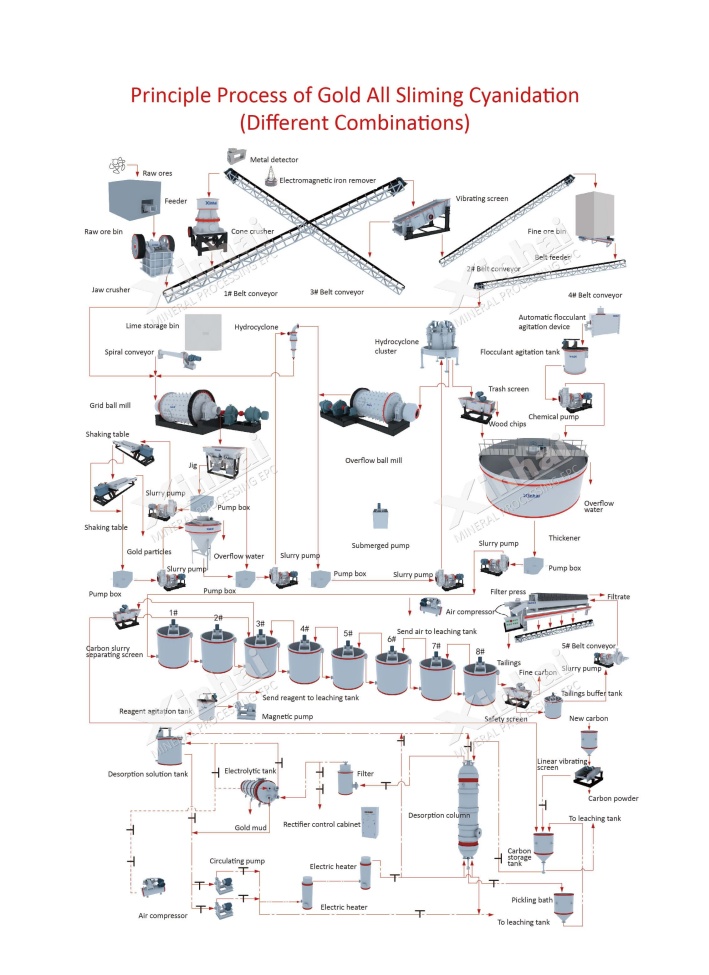

CIL stands for Carbon-In-Leach, a cyanidation process where leaching and adsorption occur simultaneously. The carbon in pulp /leach gold extraction process (CIP method and CIL method) is to put activated carbon into the cyanide slurry, adsorb the dissolved gold on the activated carbon, and then extract the gold from the activated carbon.

The CIL process includes several stages: crushing and grinding, debris removal, pre-leaching thickening, leaching with activated carbon adsorption, desorption of gold-loaded carbon, electrowinning, smelting, and carbon regeneration. This process mainly including leaching raw material preparation, agitation leaching and countercurrent carbon adsorption, gold-loaded carbon desorption, electrowinning, smelting ingot, carbon regeneration and other operations.

Equipment used includes crushers, ball mills, linear vibrating screens for debris removal, thickeners, leaching tanks with aeration systems, adsorption tanks with activated carbon columns, desorption electrolysis systems, and smelting furnaces.

Cyanidation gold extraction process is more complicated than flotation, but the gold recovery rate is higher. The recovery rate of CIP and CIL can be basically stabilized at 80%, and can be even more than 90%. Additionally, it has strong adaptability to complex ores containing clay or graphite.

Flotation is ideal for sulfide-rich ores or quartz vein ores with uneven distribution. This gold ore beneficiation process is mainly based on flotation, which is suitable for ore that has close symbiosis of gold and sulfide and can only be recovered by smelting method. On the other hand, cyanidation gold extraction process has strong adaptability to gold mines, especially to ores containing clay, graphite, asphalt shale, iron oxide and other natural adsorbents and to other complex arsenic gold ore.

CIL generally offers a higher recovery rate exceeding 90%, while flotation offers moderate recovery but at a lower reagent cost. Cyanidation gold extraction process is more complicated than flotation, but the gold recovery rate is higher. Flotation gold extraction process is not only simple in process Therefore, in terms of cost, gold cyanidation is much higher than flotation.

Either of these two gold extraction processes will produce substances that damage the environment. At present, eco-friendly gold leaching reagent has been developed as a substitute for traditional cyanide reagents to reduce the damage to the environment. Hence, waste treatment and chemical management are vital parts of both processes.

CIL involves more stages like adsorption and desorption which require significant energy input. Flotation consumes less energy per ton processed but might require reprocessing for complete recovery.

Gold CIL case: This project is a 400/500 TPD gold ore processing plant utilizing the Carbon-in-Leach (CIL) method. We provided a comprehensive EPC solution, including engineering design, high-standard equipment featuring Siemens motors, SEW reducers, and ABB electrical components, as well as installation, commissioning, and automation systems. The plant was successfully commissioned in July 2024 and is now operating stably, achieving a processing capacity of 500 tons per day with a gold recovery rate of 92%.

Gold flotation case:Xinhai provided mineral processing test research and flowsheet design for a Cambodian gold project. Based on the results, a combined gravity-flotation process was designed, along with a dewatering circuit for tailings disposal. The cyclone overflow gravitates to a high-efficiency agitator for reagent conditioning and then to SF-2.8 flotation cells for roughing, cleaning, and scavenging. This circuit efficiently produces a final gold concentrate and manages tailings.

Important considerations include ore composition, mineral liberation size, presence of sulfides or carbonaceous material, cost constraints, environmental compliance needs, and available infrastructure.

Flotation is better suited for sulfide ores or when cost constraints are tight. CIL should be selected when high recovery is essential or when dealing with complex refractory ores. The most suitable one, the better.

Some operations combine both methods—first using flotation to concentrate sulfide-rich material followed by CIL for higher recovery. This hybrid approach maximizes yield especially for complex ores.

Fresh ideas in greener chemistry are bringing out cyanide-free leaching stuff that cuts down on poison while still getting the job done pretty well. These kinda breakthroughs really matter for mining that doesn't wreck the planet.

A custom-fit plan, built off a close look at your ore samples, pretty much guarantees the best results. Getting pro input helps match up what technically works with what makes sense money-wise.

Gold flotation's easier to set up, cheaper upfront, but you get okay-ish recovery rates. Gold CIL's more involved, yet it pulls way higher yields, specially with tricky ores.

Always run ore tests first. Think about the rock type, eco concerns, how much gold you wanna grab, your budget for gear, and how quick you need things running before picking flotation or CIL.

Contact Xinhai Mining for customized gold processing solutions

Tailor-made fixes from lab runs can boost profits a bunch. Grab some expert tips for a smooth, effective ore-dressing plan.

Q1: What types of ores are best suited for flotation?

A1: Flotation shines with ores loaded in sulfides or those quartz veins where tiny gold bits are scattered all through the waste rock.

Q2: Why does CIL offer higher recovery rates?

A2: Cause the dissolving and grabbing happen at the same dang time, with activated carbon snatching the melted gold straight outta the mush.

Q3: Is it possible to use both flotation and CIL together?

A3: Yup. For messy ores or when you're chasing every last speck of recovery, mixing the two can work wonders.

Q4: Which method is more environmentally friendly?

A4: Both leave a mark on nature, but fresh green reagents are makin' things better, especially around cyanide steps.

Q5: How do I determine which method is best for my mine?

A5: Get a solid mineral processing test done by pros to check out your ore's quirks before decidin.