If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Iron ore plays a vital role in making steel, and the two big players everyone talks about are magnetite and hematite. Getting a handle on what sets them apart really matters for folks running mines, putting money into projects, or depending on iron supplies for their businesses. The gaps between them show up in everything from how they look and behave to the ways we dig them up, clean them, and even think about the planet. Here, we’ll poke around their traits, check out some clever digging and upgrading tricks, plus peek at greener ways popping up lately.

Magnetite, or Fe₃O₄, packs more iron punch and sticks to magnets like crazy, which makes pulling it apart in processing a breeze. Hematite—Fe₂O₃—carries a tad less iron and barely reacts to magnets, so sorting it out takes fancier steps and extra effort.

Magnetite ore is a silica-type ore, in which the main iron minerals are magnetite, but also contains a small amount of sulfide minerals, and accompanied by cobalt-nickel-vanadium and other non-ferrous metals. Hematite ore contains a small amount of magnetite and has uneven distribution of impurities and a large number of fine particles. Its properties are more complex. These inherent differences dictate the choice of mining and processing technologies.

Hematite mining mostly goes after those near-the-surface spots with open-pit methods. Folks often use coarse-grained gravity separation for hematite ore deposits that boast a solid geological grade (around 50%), though the ore body tends to be on the skinny side or packed with extra interlayers. This setup lets the crew chuck out waste rock right from the get-go, which really bumps up the whole operation’s efficiency.

Hematite digs usually target shallow stuff, straight-up open-pit style. That chunky gravity separation works great when the hematite ore deposits hit a decent geological grade (like 50%), but yeah, the ore body’s kinda thin or jammed with interlayers. Means the team can ditch the junk rock early on—saves a ton of hassle and keeps things running smoother.

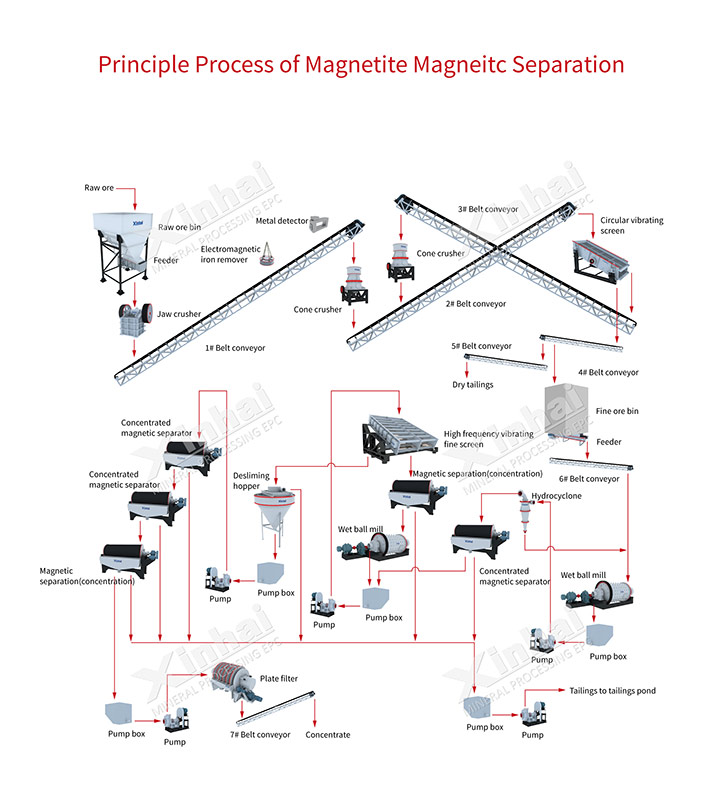

Magnetite mining often requires more intensive methods due to deeper deposits and complex ore structures. The sorting process of magnetite ore is mainly two to four stages of crushing, and in the crushing process with one to two stages of dry magnetic separation. This multi-stage approach ensures optimal recovery of magnetic minerals while minimizing energy usage.

Both types of mining generate tailings that must be managed responsibly. While providing solutions for efficient development and utilization of resources, Xinhai paid great attention to environmental protection. Innovative dry tailings disposal systems and water recycling methods are increasingly integrated into modern operations to reduce ecological footprints.

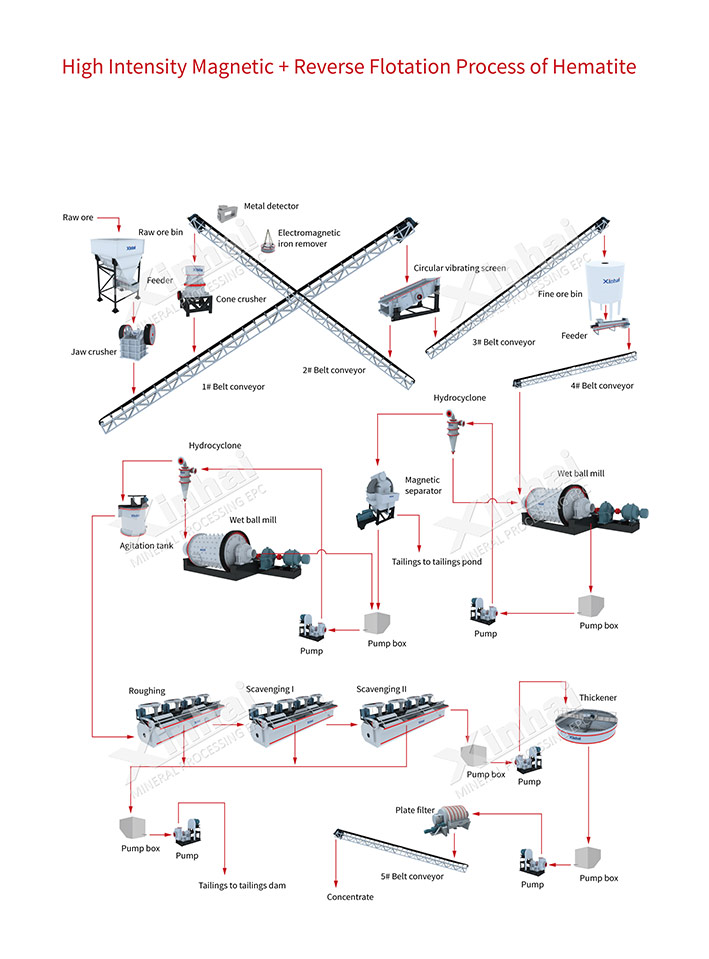

Hematite’s weak magnetic properties demand complex processing flows. The development and utilization of fine-grained embedded hematite ore has promoted the development of beneficiation processes such as hematite flotation, gravity separation, strong magnetic separation and roasted magnetic separation. Roasting-magnetic separation is particularly effective for transforming hematite into magnetite to simplify downstream processing.

Magnetite’s strong magnetism allows simpler yet highly efficient processing. Based on the physical properties of magnetite ores, the most effective beneficiation method is to recover magnetic minerals by magnetic separation and associated sulfide minerals by flotation. Multiple grinding and magnetic separation stages ensure high-purity concentrate.

The magnetic separation-flotation process uses flotation as the main process to sort the hematite concentrate, with coarse-grained hematite and magnetite recovered by gravity separation and fine-grained magnetite recovered by magnetic separation. This contrast highlights that while magnetite can often be processed using fewer stages, hematite usually requires hybrid processes involving flotation or roasting.

Both ores are indispensable in steelmaking. Magnetite is often used in coal washing as a dense medium due to its magnetic nature. Hematite is also used as a pigment and in heavy media separation applications. Additionally, magnetite’s higher iron content makes it more desirable for producing high-grade steel.

Fresh tech ideas aim to cut down on power use while boosting how much ore we pull out. For that tough hematite-magnetite quartzite packed with crystals, gravity separation handles the bigger chunks pretty well, and strong magnetic separation or flotation takes care of the finer stuff. These fresh approaches are shaking up beneficiation methods all over the world.

Looking after the environment is turning into everyday stuff now. In this setup, Xinhai came up with smart, practical fixes for dust, noise, waste water, and tailings coming from the processing plant, making the whole mine build-out greener and more responsible. Dry tailings disposal saves a ton of water, sure, and it makes the spot safer too by cutting chances of dam failures.

Conclusion

Understanding the nuanced differences between magnetite and hematite—from their mineralogical properties to their beneficiation flows—is crucial for maximizing operational efficiency and sustainability. As global demand for iron continues to rise, innovative techniques like roasted magnetic separation for hematite or multi-stage magnetic separation for magnetite will be vital.

To explore how your project can benefit from advanced processing technologies or sustainable mine design, we invite you to contact Xinhai Mining today for a customized EPC+M+O solution tailored to your iron ore challenges.

1. Which iron ore is more economically viable—magnetite or hematite?

Magnetite generally yields higher-grade concentrates but requires more energy-intensive processing; hematite is easier to mine but needs complex beneficiation.

2. What is roasted magnetic separation in hematite processing?

This method is to magnetically roast hematite ore to convert hematite or martite into magnetite, and then use a weak magnetic field magnetic separator for separation.

3. Are dry tailings disposal systems effective for both ore types?

Yes, dry tailings systems are adaptable and provide environmental benefits regardless of whether the source material is hematite or magnetite.

4. Can both ores be processed together if found in the same deposit?

For the beneficiation of hematite - magnetite ore, now mostly use the magnetic separation - gravity separation process, magnetic separation - flotation process or gravity separation - magnetic separation - flotation process.