If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

In the process of investing in a molybdenum mine, once the Feasibility Study Report is completed and the mineral processing tests, or even pilot plant trials, are finished, the project moves into the crucial phase of processing plant design and construction. This is the pivotal step that bridges the gap between "profit figures on paper" and "stable output in reality." The adoption of the EPC (Engineering, Procurement, and Construction) General Contracting model and the development of an intelligent processing plant are fundamental to ensuring the project is commissioned on time, stays within budget, and meets technical standards.

Designing a molybdenum processing plant is far more complex than simply drawing a few process flow diagrams and plant layouts; it is not a preliminary procedure to be treated lightly. It is a core strategic component of the entire mining investment project, characterized by high technical content and profound economic implications. Its importance is reflected in the following aspects:

• Setting the Recovery Rate Ceiling: The process flow selected during the design phase establishes the theoretical maximum for future molybdenum recovery. A design that is fundamentally flawed from the outset will be difficult to significantly improve, no matter how much effort is put into optimization later.

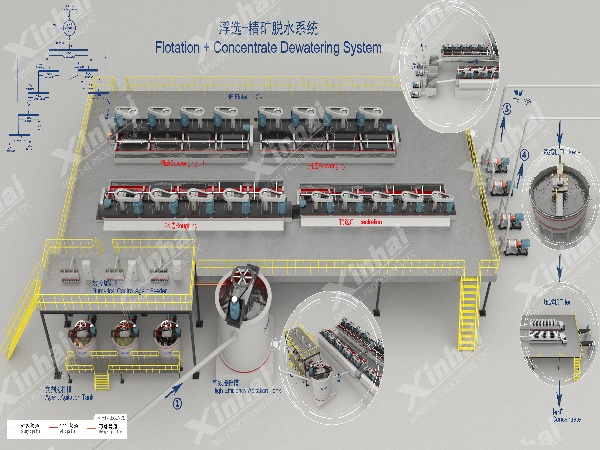

• Determining Product Quality: Design decisions regarding the number of cleaning stages in flotation, the grinding circuit configuration, and other parameters directly determine the quality of the final concentrate and its competitiveness in the market.

• Managing Ore Fluctuations: A robust plant design anticipates potential variations in run-of-mine (ROM) ore grade and mineralogy, incorporating flexibility into the process flow to ensure stable plant operation.

• Cost Estimation: Mineral processing design is essentially a one-time decision that dictates the project's operating costs for decades to come, encompassing capital expenditure (CAPEX), operating expenditure (OPEX), and costs related to labor and maintenance.

The traditional Design-Bid-Build (DBB) model involves separate entities for the design institute, equipment suppliers, and construction contractors. This structure often leads to the following issues:

• Unclear Responsibility: When problems arise, it easily devolves into a cycle of mutual blame: "Design says the equipment failed to meet standards, equipment says construction was faulty, and construction says the design was unreasonable."

• Cost Overruns: Contractors, after winning the bid, frequently submit numerous variation claims, causing the final project cost to significantly exceed the initial budget.

• Technological Disconnect: Designers may lack practical experience with the latest equipment or operational feedback, resulting in a design that "looks good but is not practical to operate."

The EPC General Contractor essentially integrates the work of multiple parties, assuming full and sole responsibility for the project's design, procurement, construction, and commissioning. The advantages are clear:

• Investment Predictability: We utilize a Fixed-Price Contract. This means that the construction cost is locked in at the project's inception. The owner's risk of a "budget black hole" is effectively transferred.

• Schedule Certainty: Design, procurement, and construction are seamlessly coordinated internally. Procurement can inform the design early on, and construction methods can optimize design details. This deeply integrated, parallel-track approach can shorten the project schedule by 20% to 30% compared to the traditional model, where delays are often unavoidable.

• Perfect Alignment of Drawings and Equipment: Xinhai is not only the designer but also a manufacturer of core equipment (such as large ball mills and flotation machines). This ensures that every process intention in our design is precisely realized in the equipment manufacturing, eliminating the disconnect where "the drawing says one thing, and the equipment is another."

• Operational Experience Feeds Back into Design: We have accumulated extensive data from mine production and operation (M+O). We know which areas are prone to material buildup, which pipeline layouts facilitate maintenance, and which control parameters are sensitive to recovery rates. Consequently, our designs are imbued with an "operational mindset" from day one, aiming to build a plant that is "functional and profitable," not just "compliant with specifications."

To understand how our full-process service systematically addresses challenges at every stage of mine development, please refer to the article: Comprehensive Molybdenum Mining Development Solution.

Xinhai integrates the construction of intelligent processing plants into every project, evident in both the design and construction phases.

• 3D System Design (BIM): We "build" the entire plant using a 3D digital model. Will pipes collide with beams and columns? Is there enough space for maintenance? Can the equipment be hoisted smoothly? All these potential issues are identified and resolved before ground is broken. This can reduce on-site rework by over 70%.

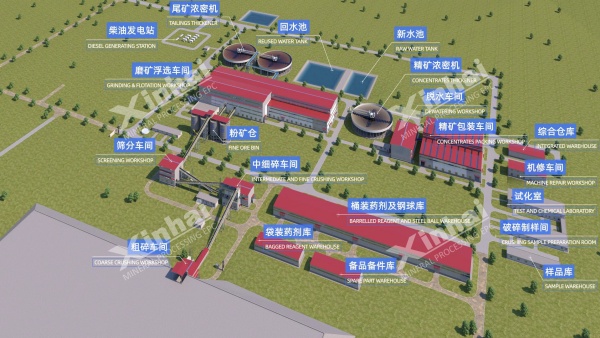

• Modular Construction: We break down the complex processing plant into a series of standardized functional modules (e.g., crushing module, grinding-flotation module, dewatering module). These modules are prefabricated in our standardized workshops with the precision of manufacturing instruments, then transported to the site for rapid assembly. The advantages of this approach are higher quality, shorter construction time, and enhanced safety.

Challenges: The project site is in a cold region with a short effective construction period; environmental protection requirements are extremely stringent; the owner needed rapid commissioning to capture a market window.

Our Practice:

1. Adopted the full-process EPC General Contracting model to lock in costs and a critical 18-month schedule.

2. Applied 3D collaborative design to resolve all pipeline collision issues in advance.

3. Used modular design and prefabrication for the main process sections, allowing module fabrication to proceed in the workshop during winter and rapid on-site hoisting in the spring.

4. Integrated the concept of a Green Mine into the design, with a target water recycling rate of 95%.

Outcome: The project achieved integrated commissioning two months ahead of schedule and was successfully started up on the first feed. Investment was strictly controlled within budget, and all environmental indicators passed inspection on the first attempt. The plant was inherently designed for high efficiency and clean operation from its inception.

Challenges: The ore had complex mineralogy, fine dissemination, and was difficult to process; the project site was at a high altitude with a scarcity of skilled technical labor; the owner's team lacked operational experience.

Our Practice:

1. "Test First, Design Later": Conducted extensive mineral processing and metallurgical tests in our CNAS-accredited laboratory, innovatively determining the core process as "Stage Grinding - Asynchronous Flotation."

2. Designed Highly Automated and Remote Support Systems: Significantly reduced reliance on skilled on-site operators, with critical control parameters guided remotely by our expert center.

3. EPC Delivery + Initial Operational Support (EPC+O): After delivering the plant, we deployed an operational team to maintain production for one year, ensuring stable performance indicators and training a qualified technical workforce for the client.

Outcome: The molybdenum recovery rate consistently met the design target under extremely challenging ore conditions. The project successfully overcame geographical and human resource constraints, becoming a benchmark for mining development in the region.

The design and construction phase of a molybdenum processing plant is the critical step where vision becomes reality. It is a solid, connecting link in the "Exploration - Decision - Design - Construction - Operation - Optimization" full-process solution. Choosing the right model and partner means that risks are controllable and the future is promising.

If you have completed your preliminary feasibility study report, we welcome you to contact us. We will prepare a Preliminary Design Proposal and EPC Implementation Plan for you.

If your project is still in the assessment phase, please refer to the article: How to Avoid Pitfalls in Molybdenum Mine Investment?