If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

In recent years, the role of molybdenum in the new energy sector has become increasingly prominent. However, molybdenum mining development today faces numerous challenges: declining ore grades, stricter environmental regulations, and rising development costs. Traditional development models can no longer meet the demands of modern mining. In this context, Xinhai introduces the "EPC+M+O" comprehensive molybdenum mining development solution, assisting clients through the entire process from exploration and evaluation to intelligent operations.

Scientific initial decisions determine whether a project can proceed smoothly. In this stage, Xinhai provides clients with a triple guarantee:

√ Resource verification and evaluation based on international standards (JORC/NI 43-101), ensuring the authenticity and credibility of resource data.

√ Systematic mineral processing test research and pilot plant testing conducted by CNAS-accredited laboratories accurately determine ore processability and key technological parameters.

√ Compilation of a practical and feasible feasibility study report integrating multi-dimensional factors, including technology, economics, market, and environment.

We understand that each mine is unique. In a large molybdenum project in Inner Mongolia, through over six months of systematic testing, the Xinhai team identified critical mineralogical characteristics difficult to process with conventional methods. Consequently, we innovatively proposed a staged grinding-classification flotation process, increasing the designed recovery rate by 8.5 percentage points compared to the industry average. This alone unlocked potential value worth billions of RMB for the client.

In the traditional development model, design, engineering, construction, and equipment procurement are sourced from different suppliers, which can create hidden risks for the entire project, potentially leading to design deviations from reality, budget overruns, and project delays. Xinhai's "EPC Turnkey" model avoids these issues. We are not merely equipment suppliers or design institutes, but an integrated solution provider with ultimate responsibility for the entire project. Under this model:

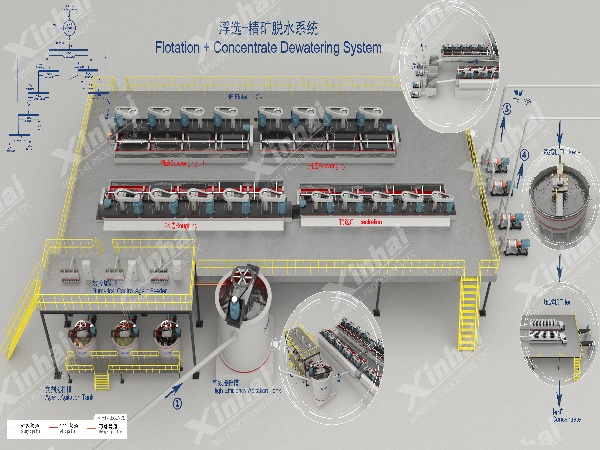

Customized Process Design: Based on test data from Stage 1, we tailor suitable process flows for each mine, ensuring technology perfectly matches ore characteristics.

Intelligent Plant 3D Design: Utilizing advanced BIM (Building Information Modeling) technology, we construct and debug the entire processing plant in a virtual environment, identifying and resolving potential spatial conflicts or pipeline interference issues in advance, reducing on-site construction changes by over 70%.

Core Equipment R&D & Supply: With in-house equipment R&D capability, Xinhai supplies the full suite of core equipment—from crushers and ball mills to flotation machines and thickeners—ensuring seamless compatibility between equipment performance and process requirements, and avoiding issues like mismatched equipment.

Construction Management: Xinhai implements internationally advanced project management methodologies. Through meticulous schedule control, standardized quality systems, and strict cost monitoring, we ensure project delivery on time, within budget, and meeting all design specifications.

In a Hebei molybdenum project, Xinhai completed the process from design to commissioning in just 16 months, nearly 30% faster than similar industry projects. The plant achieved successful production upon initial startup, with all indicators exceeding design standards, setting a benchmark for cooperation between local state-owned mining platforms and professional service providers.

Project completion is just the beginning of value creation. The key to long-term profitability lies in achieving consistent, optimized production. Many owners face challenges such as fluctuating production indicators, high operational costs, safety and environmental pressures, and shortages of skilled personnel.

Xinhai's "Operations & Maintenance (M+O) Management" service is a systematic solution designed to address these pain points. We go beyond dispatching a few technicians; we export a complete management system and continuous optimization capability:

Intelligent Production Management System: IoT sensors collect real-time production data, while AI algorithms optimize process parameters, enabling "autonomous operation." In practice at a Jiangxi molybdenum mine, this system improved flotation recovery rate stability by 40% and reduced reagent consumption by 15%.

Fine-tuned Control of Key Indicators: Precise tracking of metrics like "recovery rate-grade-cost" ensures production remains in an optimal state through daily, weekly, and monthly analysis and feedback cycles.

Preventive Maintenance System: Predictive maintenance based on equipment operating data replaces traditional reactive repairs, increasing Overall Equipment Effectiveness (OEE) by over 25% and reducing unplanned downtime by 80%.

Professional Operations Team: We provide not just a management framework but a complete team—from plant managers and engineers to operators—solving the fundamental problem of talent shortage in remote mining areas, while also training local technical personnel for the client.

Through operations management, we helped a medium-sized molybdenum enterprise in Henan reduce per-ton ore processing costs by 22% over three years while increasing the recovery rate by 3.1 percentage points, building a solid cost advantage amidst molybdenum price fluctuations.

Many older processing plants built in the 1980s-90s face issues like aging equipment, outdated processes, non-compliance with environmental standards, and low resource utilization. Meanwhile, new demands like digital transformation, green mine construction, and comprehensive resource utilization compel these plants to upgrade.

Xinhai's technical upgrade services primarily include:

Old Plant Technical Revamp: Targeted measures like localized process optimization, key equipment upgrades, and automation retrofits deliver significant benefits with relatively small investments.

Automation & Digitalization Upgrade: We offer a stepwise upgrade path from single-machine automation to full-plant intelligence. The application of digital twin technology allows managers to monitor every detail of underground mining, processing flows, and tailings dam safety in real-time from the office.

Green Mining & Comprehensive Resource Utilization: We have developed technologies for recovering associated elements in molybdenum ore, re-extracting molybdenum from tailings, and wastewater recycling—not only meeting environmental requirements but also creating new profit streams.

Asset Revitalization Strategic Consulting: For mines idled due to various reasons, we offer a complete reactivation package—from technical assessment and solution design to financing advice—turning "dormant assets" back into value creators.

Xinhai's full-process solution creates value beyond traditional models due to three key advantages:

Unlike traditional service providers responsible for single stages, we assume ultimate responsibility for the project's entire lifecycle. This model eliminates responsibility gaps and finger-pointing between design, construction, and operations, ensuring optimizations at every stage aim for overall project benefit. In a Zimbabwe 2-million-ton-per-year lithium project, this "end-to-end accountability" model enabled us to complete the journey from design to achieving nameplate capacity within 18 months, setting a new speed record for African mine construction.

We possess a comprehensive R&D system—from basic mineralogy research and mineral processing testing to equipment development—centered around our CNAS-accredited laboratory. All design plans adhere to the principle of "test first, design later," replacing assumptions with data and empirical evidence. Over 1,000 mineral processing test reports annually form the most solid foundation of our technical expertise.

Project experience across over 100 countries and regions has equipped us not only with technical expertise for complex ores but also with cross-cultural, multi-standard project management capabilities. Whether it's high-altitude mines in South America, tropical rainforest operations in Southeast Asia, or remote sites with weak infrastructure in Africa, we provide tailored solutions adapted to local conditions.

Molybdenum mining development is a systematic engineering endeavor integrating technology, management, and capital. Choosing Xinhai means gaining not just a series of services, but a long-term partner accountable for the project's outcome, a globally validated systematic methodology, and a professional technical team with decades of mining industry expertise.

No matter your current stage—evaluating resource potential, planning a new project, seeking operational optimization, or considering technical upgrades—Xinhai Mining Equipment can provide the right solution for you.

Take Action Now:

If you have a specific project need, please contact our expert team via WhatsApp: +86 138 1151 0145 for a customized solution consultation.