If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Mine general contracting is a "turnkey" engineering model in which a single contractor is responsible for the entire mining project. The contractor is responsible for the full process from design to commissioning (EPC). By integrating resources, optimizing the process flow, and transferring risks, the owner is provided with a mine that is delivered on time, within budget, and meets performance requirements. This model places high demands on the contractor's technical strength, project management, and risk-bearing capacity.

The services that a general contractor of a mine can provide to customers include:

Ore dressing test: Analyze the material composition and chemical properties of the ore, conduct tests on beneficiation methods, and issue test reports. Pilot tests can be further conducted if necessary.

Engineering design: Includes mining plan and construction drawing design, overall layout of the beneficiation plant, process flow design, infrastructure design, automation system design, and tailings pond design.

Equipment manufacturing and procurement: Equipment is manufactured based on test results. If the contractor cannot produce certain equipment independently, it must be procured from other manufacturers.

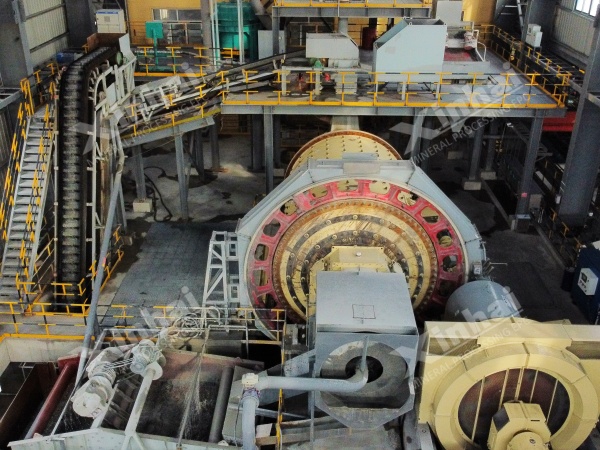

Construction and installation: The contractor is responsible for the civil construction of the plant and the installation of equipment.

Commissioning and trial operation: After equipment installation, the general contractor is responsible for equipment commissioning and trial operation until the plant is successfully put into production.

Customized process flow is developed based on the ore type, project cost, and natural conditions at the site. Xinhai’s design team configures equipment and processes according to the results of mineral testing and the customer's basic mine data. The design follows principles that promote efficient production, ease of management, production safety, land conservation, and reduced infrastructure investment. Xinhai is committed to providing customers with professional and reliable mine design solutions.

Investment cost can be predetermined to reduce uncertainty.

Civil design, procurement, and construction are all undertaken by Xinhai. After the feasibility study report or preliminary design is completed, investors can enter into an EPC contract with a predetermined total investment. EPC projects typically adopt a lump-sum contract model, where the contract price is fixed in advance, helping investors control costs and minimize future uncertainties.

EPC stages—such as installation, commissioning, civil construction, and steel structure fabrication—are efficiently and closely integrated. Civil construction is a key factor affecting installation. Xinhai’s installation team can seamlessly mobilize to the site, ensuring smooth coordination and accelerating project progress. This collaboration significantly shortens the construction timeline, enhances overall project efficiency, and ensures timely project delivery and production start-up.

It is worth noting that test runs often begin before civil construction is fully completed. By the time final commissioning ends, civil construction is also usually finished, allowing the entire project to be delivered to the customer as a complete unit.

Design first, simultaneous construction and installation.

Unlike traditional DB (Design-Bid) models, the EPC model does not require the design phase to be completed before construction can start. Instead, construction and installation can proceed in parallel with design, saving time and enabling faster production start-up.

Hard Power: Two Large Factories + One Pilot Center

Headquarters Factory: This is the company’s core operational area, housing R&D and design departments such as the Mining Research Institute, Mining Design Institute, and Mechanical Design Institute. It also undertakes key functions related to the company's daily management and operations.

Intelligent Manufacturing Industrial Park: Equipped with an intelligent high-end equipment production center, mineral processing test, pilot and design center, mineral processing experience center, and a mining automation and intelligent R&D center, it is committed to promoting intelligent and high-end development in the mining service industry.

Pilot Center: Covering an area of about 2,000 square meters, it is equipped with facilities for small-scale tests and semi-continuous industrial tests. It can conduct precise research for more than 70 types of minerals and includes standard test equipment for crushing, screening, grinding, and various separation processes.

Soft Power: Mineral Processing Experts + Rich Experience

Xinhai has more than 300 mineral processing experts, each with over 15 years of industry experience. To date, over 2,500 projects have been completed, including mine design, mineral research, and equipment supply, among which more than 600 are EPC+M+O engineering projects. Xinhai possesses expertise in the processing of more than 70 types of ores and has applied for multiple patents.

Efficient Delivery, Optimized Process

Xinhai Mining has extensive experience in both domestic and international mine project management and construction, with more than 600 general contracting projects across various minerals and challenging terrains.

Xinhai has demonstrated strong technological innovation and efficient execution in numerous projects, providing customers with reliable and high-efficiency mining solutions, and has established a solid reputation and industry benchmark in the field of mining project contracting.

√ Case 1: Zimbabwe 2 Million t/a Lithium Mine Project

Process Flow: Screening → Petalite heavy medium separation → Grinding and classification → Tantalum and niobium gravity separation → Desliming → Mica flotation → Spodumene flotation → Concentrate dewatering → Tailings thickening and discharge

Project Highlights:

·Conducted in-depth project research and field investigation; Xinhai Design Institute customized the process flow and overall project plan

·Overcame challenges such as material shortages and rainy season construction in Zimbabwe by adopting a modular steel structure, completing construction in just one year and achieving the designed production capacity

·Deployed an intelligent mining system and environmentally friendly tailings technology, realizing efficient and green modern mine operations

√ Case 2: 1,500 t/d Polymetallic Ore Flotation Expansion Project (Silver, Lead, Zinc, and Gold)

Process Flow:

The expansion was designed by Xinhai Design Institute based on the original production process, including process optimization, equipment selection, and configuration planning.

The plant adopted a process flow of one-stage grinding (a gravity separation circuit was integrated in grinding for gold recovery) and two-stage flotation.

Project Highlights:

·Fully considered the actual geographical, geological, and climatic conditions to optimize the process flow and layout design, ensuring economic benefits

·Addressed challenges such as limited construction space in mountainous terrain, the need for demolition and reconstruction, and heavy rainfall/flood season. Xinhai efficiently organized the construction, completing it ahead of schedule and achieving target output

·Emphasized environmental protection by implementing the "three wastes" treatment principle, combining source control with tail-end treatment, creating an eco-friendly modern mining operation

√ Case 3: Guinea 15,000 t/d Gold Mine Project

This project was undertaken by Xinhai Mining as a full-industry-chain EPC+M+O service provider, covering project investigation, engineering design, equipment manufacturing, on-site installation, and operation management.

Process Flow:

Raw ore slurry preparation → Grinding and classification → Gravity separation → Cyanide leaching → Desorption electrolysis

Supporting facilities include the beneficiation plant, power distribution room, diesel generator room, and more.

Project Highlights:

·Adopted a combined steel structure solution (prefabrication of key surface structures such as ore silos and on-site assembly), addressing the high cost of concrete locally, saving investment, accelerating construction, and ensuring structural aesthetics

·Optimized the coordinated control across the entire process—from crushing and grinding to tailings transportation—realizing advanced and rational full-process automation of the beneficiation plant

·Practiced the green mining concept by using low-toxicity and eco-friendly leaching agents to ensure worker safety and achieve 100% recycling of production wastewater, reaching zero discharge standards. This fully demonstrates Xinhai’s capability to deliver efficient, intelligent, and eco-friendly full-cycle services for large-scale gold mine projects

Conclusion

Xinhai Mining provides services covering the full mining industry chain—from mineral processing tests, mine design, mining engineering construction, mineral processing plant construction, tailings pond engineering, to integrated contracting and operations. With comprehensive business coverage, deep expertise, and rapid response, Xinhai delivers highly integrated and customized one-stop EPC+M+O solutions across the entire mining value chain.