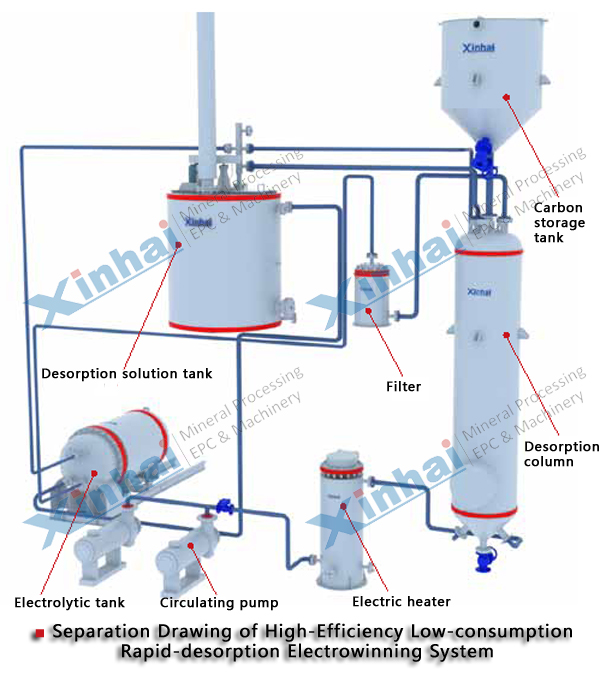

A set of gold beneficiation equipment for obtaining gold mud from gold-loaded carbon through desorption and electrowinning under high temperature and high pressure conditions. 【Processing capacity】: ≥3.5kg/t 【Scope of application】: Used in cyanidation alchemy to extract solid gold from gold-loaded carbon.

Under the conditions of high temperature (150℃) and high pressure (0.5MPa), the desorption rate reaches more than 98%;

The temperature of desorption and electrolysis is the same, no heat exchange is required, and the power consumption is 1/4 to 1/2 of the conventional system due to the fast operation;

The non-toxic desorption combination agent contains carbon activator, which can regenerate the carbon, and the poor carbon does not need to be regenerated by fire, which saves the cost of carbon regeneration;

Cyanide-free: no need to add sodium cyanide to the desorption solution, low cost and less pollution;

The gold mud has high grade, no reverse electrolysis is required, and the extraction is easy;

Safety: It has triple safety protection measures, namely the system's own intelligent, automatic pressure-limiting and pressure-releasing mechanism, and insurance safety valve.

In gold electrowinning process,when the electrolysis equipment is added with anions that are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved. After the carbons loaded with gold are desorbed, pregnant solution processes the via ionization. At last, the solid gold is attained.

| Model | Suitable Scale | System Equipment List | System Instrument List | Operation Parameters | |

| Mine Scale (t/d) | Raw Ore Grade (g/t) | ||||

| GJD-200 | < 150 | 2~8 | $1 Desorption Column $2 Filter $3 Electrolytic Tank $4 Circulating Pump $5 Electric Heater $6 Carbon Ejector $7 Air Compressor $8 Desorption Solution Tank $9 Clarified Water Pump $10 Acid Storage Tank $11 Magnetic Pump $12 Carbon Storage Tank $15 Control Cabinet $16 Silicon Rectifier Cabinet $17 Pickling Tank | B1 Electric Resistance Remote Transmission Diaphragm-Seal Pressure Gauge B1 Pressure Indication Adjusting Meter B2 Diaphragm Pressure Gauge B3 Vortex Shedding Flowmeter B3 Flow Integrating Instrument B4 Thermal Temperature Meter B5 Temperature Sensor B5 Temperature IndicationAdjusting Meter P6 Diaphragm Pressure Gauge B7 Level Meter B9 Temperature Sensor B9 Temperature Indication Adjusting Meter | Desorption Solution: PH > 13.5 Infinite 100-110°C Electrolysis Ending: Electrolysis Current: 350-1250A Electrolysis Pressure: 2-4V 150C : 0.50-0.57MPa Electrolytic Tank: 0.45-0.52MPa |

| GJD-300 | 150~300 | ||||

| GJD-450 | |||||

| GJD-500 | 300~500 | ||||

| GJD-600 | |||||

| GJD-750 | |||||

| GJD-1000 | 500~1000 | ||||

| GJD-1200 | |||||

| GJD-1500 | |||||

| GJD-1800 | |||||

| GJD-2000 | 1000~2000 | ||||

| GJD-2500 | |||||

| GJD-3000 | |||||

| GJD-3500 | 2000~3000 | 2~20 | |||

| GJD-4000 | |||||

| GJD-5000 | |||||

| Especial | > 3000 | ||||

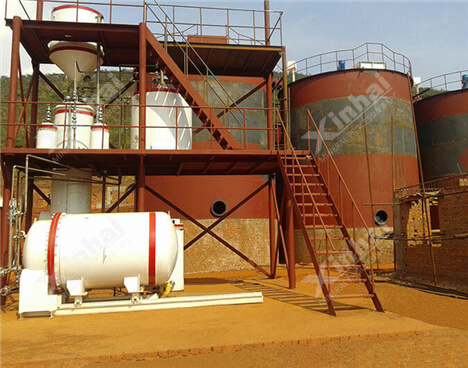

In the Zimbabwe 700tpd rock gold mine project undertaken by Xinhai, the mines are quartzite gold mines, mostly oxidized ores or primary mines with low sulfur content. The beneficiation part combines gravity separation + full-slime cyanidation carbon slurry process, that is, desorption electrolysis system for gold extraction. The extraction is efficient, fast, low consumption, low cost and high production efficiency. The gold mud of the system is of high grade and does not need reverse electrolysis, thus realizing the efficient recovery of gold.