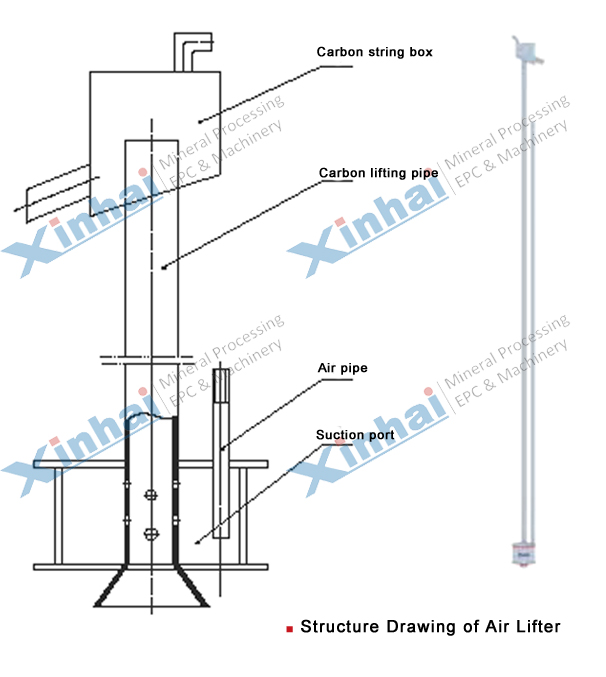

A gold ore beneficiation equipment that uses compressed air as a transmission medium to transport ore pulp. 【Processing capacity】: 3-5m 【Scope of application】: It is used to lift high density materials such as working media and concentrated concentrates in heavy media enrichment plants.

The design mechanism is scientific and reasonable, which greatly reduces the damage to carbon;

The air lifter has high efficiency, and the time for each carbon string is about 0.5 to 1 hour;

Small size, easy to install on the leaching stirring tank or adsorption tank, easy to operate and maintain;

From the design point of view, the air lift can also save the configuration height difference and area of the equipment, and reduce the investment in the plant and infrastructure.

Pressure air is inflated into air lifter, which reduces the air density of ore pulp pipe and causes the pressure difference between pipe and tank. By the action of pressure, ore pulps in tank are lifted by air lifter.

| Model | Carbon adsorption pipe specification | Air pipe specification | Application range |

| KT60 | Φ50×2.5 | DN20 | SJ2.0×2.5, SJ2.5×2.5, SJ2.5×3.15, SJ3×3.15, SJ3×3.5, SJ3.15×3.55 |

| KT100 | Φ108×4 | DN25 | SJ3.55×4, SJ4×4.5, SJ4.5×5, SJ5×5.6,SJ5.5×6, SJ7.5×8, SJ8×8.5 |

| KT125 | Φ133×4 | DN32 | SJ8.5×9, SJ9×9.5, SJ10.5×11 |

| KT150 | Φ159×4 | DN40 | SJ12×13 |

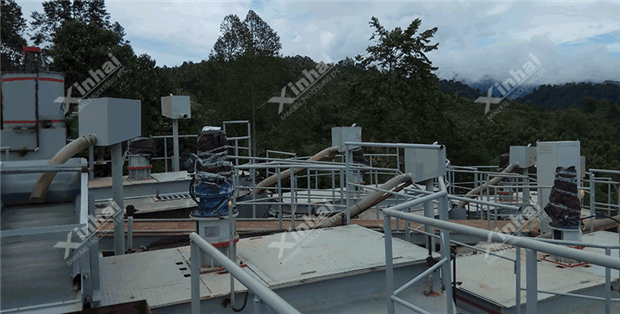

In the Zimbabwe 100pd rock gold mine project, Xinhai air lifter, as a supporting facility of the leaching tank, makes the effect of carbon extraction more obvious in the leaching tank, and can effectively prevent the activated carbon from running along the direction of the pulp; The flow in the ore and the activated carbon have a good isolation effect on the adsorption of gold, preventing the mixing of the activated carbon and the pulp, and adding additional work.