If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

When launching a mining project in Latin America, the very first—and often the most difficult—challenge investors face is selecting the right gold processing equipment. On one end of the spectrum are high-performance but extremely expensive full sets of European and American equipment; on the other are more budget-friendly options that raise concerns about long-term reliability. This decision doesn’t just affect millions of dollars in upfront capital investment—it directly determines the project’s operating cost structure and production stability for years to come.

Today, through a real case study of a successfully delivered 400 tpd Gold CIL Processing Plant EPC project in Latin America, we want to offer you a reliable new path for equipment selection when planning your own mining projects in the region.

At the project’s early stage, the investors of European background had extremely high expectations for equipment quality. Their concern was clear: in Latin America, far from major industrial hubs, any major equipment failure would lead to long repair cycles and unbearable downtime costs.

Therefore, the traditional mindset in selecting gold processing equipment favored purchasing fully imported EU/US brands, which inevitably pushed the investment budget sharply upward.

The turning point came when we proposed an innovative hybrid solution:

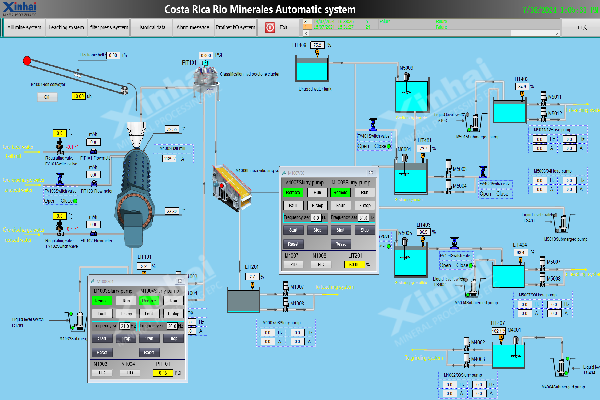

For the critical power and control systems, we adopted international brands specified by the client—Siemens, SEW, and ABB. For non-critical steel structures, auxiliary equipment, and overall system integration, design, installation, and commissioning, the work was handled by Xinhai’s Chinese EPC team.The team has extensive experience and is well-versed in international project standards.

This was not a simple “mix and match.” It was a gold processing equipment selection strategy built on deep engineering integration. It precisely addressed the core concerns of the investors—ensuring absolute reliability of key components while keeping costs under control. Eventually, this “International Core + Chinese Integration” model earned full trust and enabled the project to move forward smoothly.

Geographical distance in Latin America often magnifies operation and maintenance difficulties. If critical components fail frequently, the long waiting times and production losses can be devastating. Therefore, the first principle of gold equipment selection must be ensuring the extreme reliability of the system’s “heart” and “nervous system.”

For this project, we equipped Siemens motors and ABB electrical control systems—brands known worldwide for their strong service networks and proven durability. This provided a “double layer of protection” for long-term stable operation. Since commissioning, the core systems have maintained a record of “zero major failures,” strongly validating the effectiveness of this selection strategy.

Many Latin American mining projects are backed by mid-size mining companies or investment funds that are highly sensitive to CAPEX. Traditional gold equipment selection often falls into two extremes: “fully imported and very expensive” or “fully cheap and high risk.”

Our strategy restructures this cost model:

We allocate a significant portion of the budget to the critical components that account for 80% of the failure risk (drives, transmissions, controls), while for high-cost but mature-technology items like structural parts and conveyors, we use high-quality, cost-effective Chinese manufacturing.

This allows the project to secure international-level reliability while achieving a more competitive overall investment than pure EU/US solutions, greatly improving the project’s financial attractiveness.

A successful mining project in Latin America must overcome challenges such as cross-border procurement, multi-country standard coordination, and onsite installation and commissioning. When equipment comes from multiple suppliers, the owner often gets caught in endless coordination.

What we offer is a turnkey solution with clear responsibility boundaries.

Once you confirm your preferred brands for the core equipment, we take full responsibility for detailed engineering design, equipment procurement coordination, international logistics, onsite installation, and commissioning.

You only need one point of contact—from “equipment selection” to “achieving full production capacity.”

This model significantly reduces the common risks and management complexity seen in Latin American mining projects.

This innovative equipment-selection-plus-EPC-integration approach delivered outstanding outcomes for the Latin American project:

Stable Nameplate Capacity: The plant consistently reached the designed throughput of 500 t/d.

Strong Performance Indicators: Despite fluctuations in ore grade, gold recovery remained steady at 92%.

Smooth Operation: Since commissioning in July 2024, the production line has run consistently and reliably, reaffirming the value of the “International Core + Chinese Integration” model.

This successful case offers investors developing projects in Latin America and other emerging mining regions a replicable, low-risk, and highly efficient solution framework.

If you are planning a new Latin American mining project and seeking the optimal balance between cost-effectiveness, reliability, and compliance in selecting gold processing equipment, we would be glad to share more project details and engineering data.

Let’s work together to bring this proven “selection intelligence” and “integration capability” into your next successful project. WhatsAPP number:+8613811510145.