If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Out of the many ways to gold extraction, three methods dominate the scene: CIP (carbon-in-pulp), CIL (carbon-in-leach), and heap leaching. These approaches aren’t just slight variations — they differ a lot in how complicated they are to run, how much cash you have to sink in upfront, how much gold you actually pull out, and what kind of ore they work best on.

You’ll see CIL and CIP mostly on richer deposits or tricky, rebellious ores because they simply recover more metal. Heap leaching, on the other hand, shines when you’re dealing with big piles of low-grade, already-oxidized material — it’s cheap to build, cheap to operate, and keeps the accountants happy.

What follows is a straightforward, no-nonsense comparison of CIL/CIP versus heap leaching. Hopefully it’ll help mine owners, plant metallurgists, or anyone writing the checks figure out which route actually makes sense for their project.

The CIL/CIP processes rely on cyanidation and carbon adsorption. Carbon in pulp (CIP) is a process where finely ground ore is mixed with cyanide solution and activated carbon. The gold dissolves in the cyanide solution, and the activated carbon adsorbs the gold from the solution. CIL (Carbon-in-Leach) is similar to CIP, but the difference is that the leaching and adsorption processes of CIL are carried out simultaneously in the same equipment.

In contrast, heap leaching is a process where crushed ore is piled onto a lined pad, and a cyanide solution is applied to the surface. The cyanide seeps through the heap, dissolving gold as it percolates through the ore. The collected pregnant solution is then processed to recover the dissolved gold.

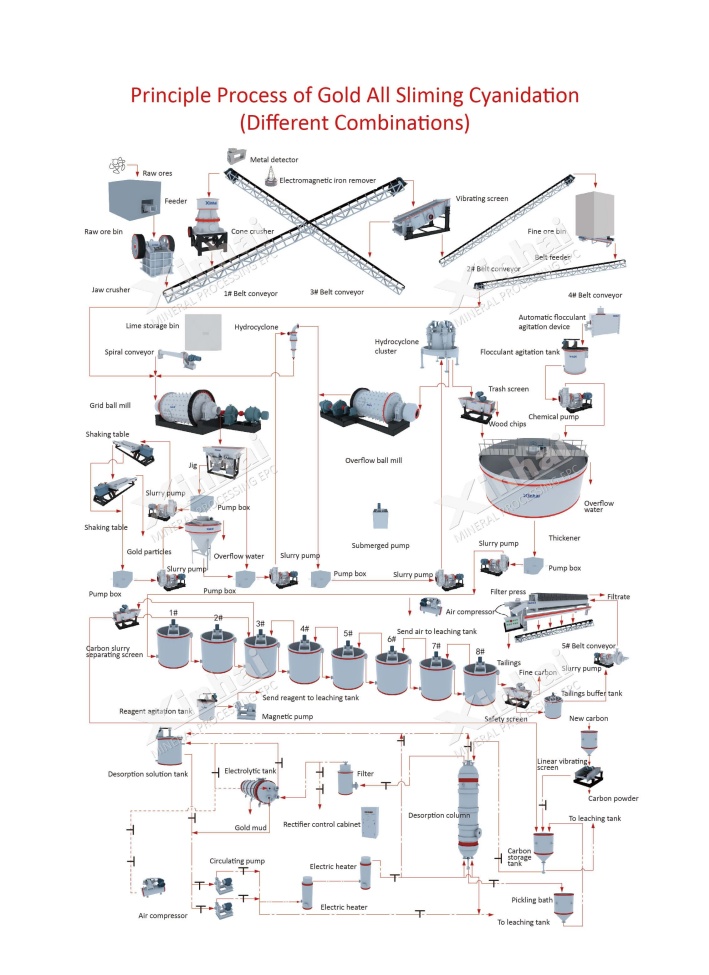

In the CIL/CIP flowsheet, the ore undergoes:

Crushing → Grinding → Leaching → Carbon adsorption → Elution → Electrowinning → Smelting.

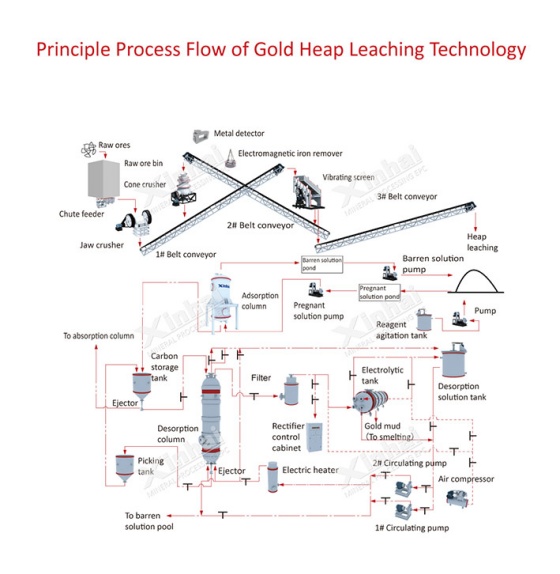

For heap leaching:

Crushing → Agglomeration (if required) → Heap stacking → Irrigation → Solution collection → ADR recovery.

The main distinction lies in how gold is dissolved and recovered—tank-based agitation vs percolation through stacked ore.

CIL/CIP methods demand significant capital investment. The initial investment for a CIP plant can be significant, particularly for the equipment required for carbon handling and processing. This includes grinding circuits, leach tanks, carbon handling systems, and elution circuits.

On the other hand, heap leaching requires lower capital investment than other methods, making it a popular choice for small to medium-sized operations. Heap leaching significantly reduces operational costs by bypassing the need for fine grinding and tank agitation.

CIL/CIP plants are designed for high-throughput operations. The process is relatively quick, with gold extraction typically occurring within hours to days, making it suitable for operations targeting rapid payback.

In contrast, the leaching process can take several months to complete in heap leaching setups due to the slower percolation rates and longer reaction times.

CIL/CIP methods are optimal for:

high-grade ores and the ability to invest in more advanced processing facilities. They also perform well on finely disseminated or refractory ores that require full liberation.

Conversely, heap leaching is ideal for operations with low-grade ores. It is especially effective on oxidized, porous ores that allow easy cyanide penetration.

CIL/CIP methods offer superior performance:

CIP is known for its ability to achieve high gold recovery rates, often exceeding 90%. CIL also offers improved performance due to simultaneous leaching-adsorption.

Heap leaching has more modest results: it often results in lower gold recovery rates compared to other methods, especially for more complex ores, typically ranging between 60%–85% depending on ore characteristics.

With CIL/CIP plants, the headaches mostly come from handling nasty cyanide-laden water — you’ve got to detox it properly, usually by blasting it with oxidants or running it over more activated carbon. Then there’s the ever-present worry about your tailings dam not deciding to take a walk one rainy night, plus trying to keep the water bill from exploding.

Heap leaching brings its own flavor of trouble. Because everything sits outside on a giant pile, any leak in the liner means cyanide can sneak straight into the ground if you skimped on the plastic or the clay layer. One tiny tear and you’re suddenly very unpopular with the neighbors (and the regulators).

Both routes are feeling the squeeze these days. Regulators, investors, and pretty much anyone with a laptop want to see less cyanide floating around, way more water getting reused instead of sucked out of rivers, and containment that actually works when it rains sideways. It’s all wrapped up in that ESG buzzword salad everyone’s obsessed with now. Mess it up, and good luck raising money or keeping your license.

In CIL/CIP systems, gold-loaded carbon undergoes desorption via thermal or chemical processes. Common systems include ZADRA (atmospheric pressure) and AARL (pressurized heat exchange) circuits which then feed electrowinning cells followed by smelting.

In heap leach circuits, recovery usually involves ADR systems—Adsorption–Desorption–Recovery—using carbon columns or zinc precipitation after solution collection.

Heap leaching isn’t standing still. People keep tinkering with better sprinklers, fancier drip lines, and smarter ways to push the solution through the pile faster and grab more gold while they’re at it. On the chemistry side, folks are testing stuff like thiosulfate or glycine instead of the usual cyanide — same job, but a lot less scary if something spills.

Some operations are getting clever and mixing things up. You’ll see heaps that later feed straight into a small CIL plant, or oxide caps getting pre-oxidized so the lower stuff actually dissolves. Throwing bioleaching into the mix or hitting the rock with some pretreatment first is catching on too, especially when the ore is being stubborn and won’t give up its gold easily.

Everyone’s trying to make heap leaching look greener. Switching to biodegradable reagents, ripping up less dirt, and running the solution in a proper closed loop so nothing sneaks out to the creek. Thicker, tougher liners and double liners are pretty much standard now if you don’t want the environmental guys camping on your doorstep.

When comparing cil/cip vs heap leaching, several factors emerge as decisive:

CIL/CIP offer higher gold recovery (>90%), fast turnaround time, but at higher cost and complexity.

Heap leaching provides a cost-effective option with lower CAPEX/OPEX but slower recovery (60–85%) and greater reliance on ore permeability.

CIL/CIP is suited for high-grade or refractory ores; heap leaching fits low-grade oxidized ores.

Both face environmental scrutiny but differ in their risk profiles: tailings vs pad leakage.

Mining companies should base their technology selection on ore characteristics, available capital, regulatory environment, and recovery goals. For projects constrained by infrastructure or targeting low-grade resources, heap leaching remains an attractive solution that balances economics with scalability.

If you are looking for gold leaching process and equipment, or want to learn about efficient gold leaching equipment, please continue to pay attention to our website, we will provide more cutting-edge industry information!