If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Titanium and zirconium are super popular these days. Aerospace, cars, ceramics, and even nuclear plants can’t get enough of them. These metals hide in zirconium-titanium ores, often called heavy mineral sands. Pulling them out is like digging for rare shells on a crowded beach—tough but worth it. This guide explains what these ores are, walks you through the classic and new ways to process them, and shows how Xinhai Mining Technology & Equipment Inc. creates smart, all-in-one solutions to get the most value from mining projects worldwide. Honestly, their work makes this hard job look almost simple!

These ores show up in beach deposits, shaped by waves and wind over thousands of years. The result is a mix of valuable minerals, perfect for projects aiming to cash in on several materials at once.

The big value comes from a few key minerals:

Ilmenite (FeTiO₃): The main source for titanium. It’s used to make titanium dioxide (TiO₂) for paints and coatings—over 90% of its use—and strong, light titanium metal. It sticks to magnets pretty well.

Zircon (ZrSiO₄): The top source for zirconium, which handles heat and rust like a boss. It’s great for ceramics, foundry molds, and zirconium chemicals. Magnets don’t bother it.

Rutile (TiO₂): A titanium champ, with more titanium than ilmenite. It’s awesome for high-quality paints and titanium metal.

Other Goodies: Monazite, which has rare earth elements but comes with radioactive issues; leucoxene, a weathered form of ilmenite; and garnet, useful in some industries.

Sorting these minerals depends on how heavy they are, whether they stick to magnets, or how they react to electricity. It’s like sorting a messy drawer of coins by weight and shine.

Why are these metals a big deal? Titanium is light and tough, great for airplane parts, medical implants, and even sports gear like tennis rackets. Zirconium laughs off heat and corrosion, making it perfect for nuclear reactors and fancy ceramics. Getting these from zirconium-titanium ores efficiently keeps costs low and meets the world’s growing needs. For example, in 2024, the aerospace sector used about 32% of global titanium, based on industry stats.

| Metal/Mineral | Key Properties | Primary Applications |

| Titanium (from Ilmenite/Rutile) | High strength-to-weight ratio, excellent corrosion resistance | TiO₂ Pigment (paints, plastics, paper), Aerospace alloys, Medical implants, Chemical processing equipment |

| Zirconium (from Zircon) | High melting point, corrosion resistance, low neutron absorption | Ceramics (tiles, sanitaryware), Refractories, Foundry molds, Nuclear fuel rod cladding, Zirconium chemicals |

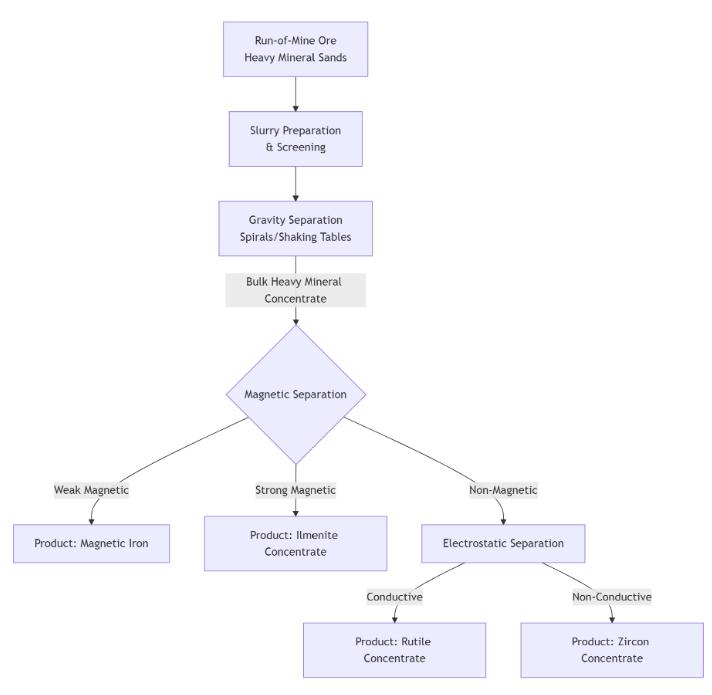

Processing these ores is about separating the good stuff from the junk. It’s a step-by-step job, using physical tricks to sort minerals. Here’s how it usually goes down.

The first step is gravity separation. Valuable minerals like ilmenite, zircon, and rutile are heavy, with a density of 4.2-4.8 g/cm³. Quartz and clay, at 2.6-2.7 g/cm³, are much lighter. Spiral chutes and shaking tables do the work, creating a heavy mineral concentrate (HMC) and tossing out up to 90% of the feed as waste. Think of it like sifting sand to keep the heavy treasures.

Next, the HMC goes to magnetic separators. A weak magnet grabs magnetite and other magnetic bits. Then a stronger magnet pulls out ilmenite, which is kinda magnetic. Zircon, rutile, and slightly magnetic monazite stay behind. It’s like using a magnet to pick out specific marbles from a pile.

The non-magnetic mix, mostly zircon and rutile, gets dried and sent to electrostatic separators. Rutile conducts electricity well, so it jumps off a charged rotor fast. Zircon, which doesn’t conduct well, hangs back. This splits them neatly, like kids running at different speeds in a race.

Even with solid methods, things get tricky. Here are the biggest headaches:

Tiny Grains: In places like Hainan, zircon and rutile are super small compared to quartz. It’s like catching dust in a storm—fines slip away during de-sliming or don’t settle right in gravity separators.

Mixed-Up Minerals: Some minerals stick together, like knotted string. This makes clean splits hard, leaving middlings that mess up the final product’s quality and yield.

Radioactive Problems: Monazite and thorite are radioactive. They need careful handling to keep workers and the environment safe.

Clay Issues: Ores can have 15-25% clay, which clogs machines and thickens slurries. If not removed early, it’s like stirring thick mud—everything slows down.

Big Costs: Traditional setups use tons of water and power, especially for drying and pumping. It’s like leaving a faucet running all day—expensive!

Xinhai Mining handles these challenges with smart ideas and tons of experience. Their “Mine EPC+M+O” service—covering engineering, procurement, construction, management, and operations—takes projects from idea to reality without a hitch.

Xinhai doesn’t guess. They run careful tests, like a chef tasting every spice before cooking. These tests figure out the ore’s quirks and find the cheapest, most effective way to process it. For example, in a 2023 project in Indonesia, their tests bumped up zircon recovery by 12% compared to standard methods.

In the Mozambique 10,000t/d project, Xinhai made the process simpler by:

Five Minus: Skipping extra steps like re-grinding or repeated separations to keep things easy.

One Plus: Adding slag removers before key machines to stop clogs.

It’s like cutting extra steps from a recipe to make it quicker but still delicious.

Xinhai uses 3D designs and modular setups to build plants fast. In Mozambique, they used the land’s natural slope for a gravity-flow system. This cut out 8 slurry pumps and saved 500kW of power compared to regular designs. That’s like swapping out old bulbs for energy-saving ones across a whole factory! Man, that’s a smart move.

Having built five titanium-zirconium plants in Mozambique, Xinhai knows how to handle fine grains, clay-heavy ores, and radioactive stuff. Their designs are safe, follow global rules, and keep things running smoothly.

Project: 10,000 t/d Titanium-Zirconium Sand Processing Plant, Mozambique

Ore Type: Coastal placer with ~90% quartz, mixed with ilmenite, zircon, and rutile.

Objective: Make ilmenite and zircon concentrates with specific grades and recoveries.

Xinhai’s Solution & Results:

Flowsheet: Screening & De-sliming → Spiral Gravity Separation (Roughing, Cleaning, Scavenging) → Weak Magnetic (Iron Removal) → Strong Magnetic (Ilmenite Concentration) → Zircon Circuit (Spirals + Shaking Tables).

Key Innovation: Used the land’s slope to cut pumping needs.

Outcome:

Ilmenite Concentrate: TiO₂ grade of 40-42%, recovery over 71%.

Zircon Concentrate: ZrO₂ grade of 31-35%, recovery over 80%.

Equipment Operation Rate: 95.45% during trials, proving it’s rock-solid.

This project proves Xinhai can turn tricky ores into big profits. Their plant ran like a well-tuned car, even with tough coastal sands.

Q1: What’s the difference between zircon and zirconia?

Zircon (ZrSiO₄) is a natural mineral from zirconium-titanium ores. Zirconia (ZrO₂), or zirconium dioxide, is a man-made ceramic made from zircon. It’s tougher, handles crazy heat, and shows up in stuff like dental crowns and oxygen sensors. Think of zircon as raw clay and zirconia as a fired pot.

Q2: Can smaller zirconium-titanium ore projects make money?

You bet! Profit depends on the minerals, their quality, and market prices. Xinhai builds plants that fit any project size, keeping costs low and profits high, whether it’s a small 1,000tpd setup or a huge one.

Q3: How do you deal with radioactive stuff like monazite?

Radioactive minerals like monazite get sorted into separate streams. Xinhai uses strict safety rules, proper storage, and helps clients dispose of them safely, following global standards. It’s like keeping spicy ingredients separate in the kitchen to avoid trouble.

Xinhai handles it all—testing, designing, building, and running the plant. They make sure your project stays on track, under budget, and gets every bit of value from your ores. Working with them is like having a trusty guide in a complicated maze. Reach out to Xinhai today for a plan that fits your project perfectly!