A gravity separation equipment that utilizes the inertial centrifugal force generated in the helical rotary motion of the pulp to realize the separation of light and heavy minerals. 【Processing capacity】: 0.15~16t/h 【Scope of application】: The beneficiation spiral chute is mainly used to separate iron, tin, tungsten, tantalum, niobium, gold, coal, monazite, rutile, zircon and other metals and non-metals with sufficient specific gravity difference with a particle size of 0.3-0.02 mm. mineral.

Xinhai spiral chute has high efficiency, high recovery rate and accurate ore separation;

Light weight, rust-proof, wear-resistant, corrosion-resistant;

Small footprint, low water consumption, simple structure, no power required;

Low operating cost and long service life;

Strong adaptability to fluctuations of ore feeding amount, concentration, particle size and grade;

The spiral chute is low in price, simple in installation, convenient in operation, small in investment and quick in return;

The frictional force formed on the emery surface makes the beneficiation effect better than other plastic surfaces.

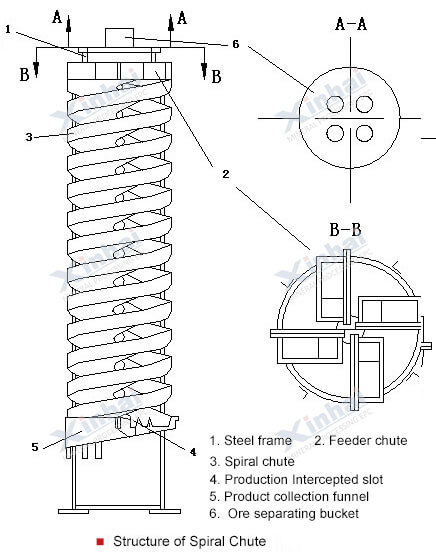

The uniform ore slurry is slowly fed to the spiral groove surface through the ore feeding trough installed at the head end of the spiral trough for sorting. The end of the spiral groove is equipped with a valve block-type product intercepting groove, and the sorted products are divided into three types according to the grade along the radial direction. The position of the regulating valve block is used to change the intercepting width of each product, and the product gathering bucket collects and derives the intercepted multi-head ore streams. The cross-section and the slope change of the curve are especially suitable for the selection of fine particle materials.

Spiral chute is suitable for the treatment of the 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, the spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer, and gold ore.

| Model | BLL-2000 | BLL-1500 | BLL-1200 | BLL-900 | BLL-600 | BLL-400 | |

| Outside Diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Screw Pitch (mm) | 1200 | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 | |

| Pitch Diameter Ratio | 0.6 | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 | |

| Lateral Dip Angle (degree) | 9° | 9° | 9° | 9° | 9° | 9° | |

| Max. Screw Numbers Per Set | 3 | 4 | 4 | 4 | 2 | 2 | |

| Feed Size (mm) | 2.00~0.04 | 0.8 ~0.037 | 0.3~0.03 | 0.3 ~0.03 | 0.2~0.02 | 0.2 ~0.02 | |

| Feed Density (%) | 30 ~55 | 30 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | |

| Capacity (t/h) | 7~10 | 6~8 | 4~6 | 2~3 | 0.8~1.2 | 0.15~0.2 | |

| Overall Dimension | Length (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

Width (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | |

Height (mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 | |

| Weight (kg) | 900 | 850/800 | 700/650/600 | 450/400/350 | 120/100/80 | 50 | |

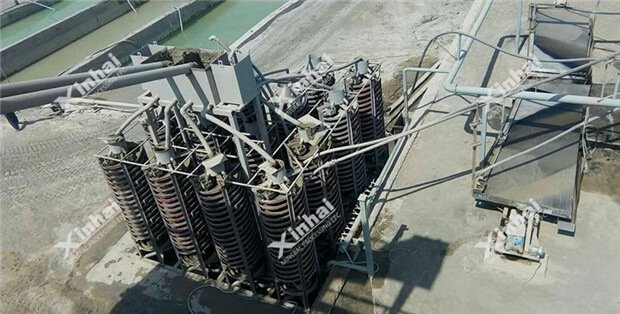

Except for a small amount of large particles, the ores of a concentrator in Shandong Haibin are mainly distributed in the -0.15mm particle size. The mine occupies a small area, but the processing capacity is large. In order to increase the service life of the spiral chute, Xinhai spiral chute manufacturer specially adds wear-resistant rubber to the inside of the spiral chute to increase the wear resistance of the machine, as well as acid and corrosion resistance. During the actual use of the machine by the customer, the mineral stratification is obvious, and the service life of the machine is extended by half a year compared with the ordinary chute.