If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Gold mining is all about pulling gold ore from the earth. You search for it, dig it up, and process it to get the shiny metal. Gold’s a big deal because it’s valuable for jewelry, tech gadgets, and as a safe bet for investors. This work keeps economies buzzing. It creates jobs, like for miners in small towns, and pushes new tech, like better drills. It also helps build stuff like roads or schools. People always want gold, whether for wedding rings or saving cash. Xinhai Mining brings smart tools and plans to make gold mining work better, helping mines hit their goals.

Gold mining’s been around forever—over 5,000 years! Ancient folks in Egypt and Mesopotamia started it. Romans got fancy, using water to blast dirt away. In the 1800s, the California Gold Rush (1848-1855) had people racing west for gold. South Africa’s Witwatersrand find later made mining huge. By the 1900s, a trick called cyanidation pulled more gold from rocks. Now, it’s a high-tech game, and companies like Xinhai Mining build full projects, using their experience to make mines greener and stronger.

Open-pit mining happens when gold’s near the surface. Workers scoop away dirt and rocks to get to the ore. Big gear, like excavators and dump trucks, does the heavy lifting. It’s cheaper for low-grade deposits, like those in Nevada’s Carlin Trend, where miners move tons of earth daily. But, it can tear up the land and hurt nature if you’re not careful. Replanting trees or fixing soil helps. Xinhai Mining plans open-pit sites and offers ways to clean up afterward, keeping things as green as possible.

Underground gold mining goes deep to find gold. Miners carve shafts and tunnels to reach it. They use tricks like cut-and-fill or longhole stoping to grab the ore. It’s like digging a secret maze. This needs strong supports and lots of safety checks. In Australia, some mines dive miles down for rich gold veins. It’s perfect for high-grade stuff. Xinhai Mining supplies gear and know-how to keep these mines safe and pulling out gold like clockwork.

Underground gold mining has some real upsides. It doesn’t mess up the land much, so animals and plants stay safe. It cuts down on waste too. Plus, it hits richer gold spots, meaning more gold for less work. Underground mines keep running, rain or shine. Good air systems and supports make them safer now. A mine in Canada, for example, uses high-tech fans to keep air clean. Xinhai Mining builds these mines to shine, sticking to tough global rules.

Gold mining’s no walk in the park. The ground can trick you—rocks might shift or ore might hide. Gold prices jump around, messing with budgets. Governments set strict rules, and breaking them costs big. Safety’s a worry too. Rocks can fall, gases might spark, or machines could fail. In 2010, a Chilean mine collapse trapped 33 miners, showing the risks. Nature gets hit hard—think dirty rivers or wrecked forests. Money’s tight too, with pricey gear and labor. Xinhai Mining steps in with solid plans. They focus on safety, smart work, and green ideas to keep mines running right.

An underground gold mine’s like an ant colony. Vertical shafts let workers and air flow in. Horizontal paths, called drifts, move ore around. Stopes are where the real digging happens. You’ve got workshops, safe spots, and pumps for water. A mine in South Africa might stretch miles, planned on computers to stay sturdy. Good layout keeps things safe and smooth. Xinhai Mining designs these setups with top tech, making sure mines are strong and efficient.

Underground gold mining needs tough tools. Jumbo drills punch holes for blasting. Load-Haul-Dump (LHD) machines scoop and haul ore. Roof bolters pin the ceiling to stop collapses. In Ghana, some mines use remote LHDs so workers stay out of danger. Fans push fresh air, and radios keep teams talking. It’s a rough place, so gear’s gotta last. Xinhai Mining provides these tools and keeps them running with regular checkups, making mines safer and faster.

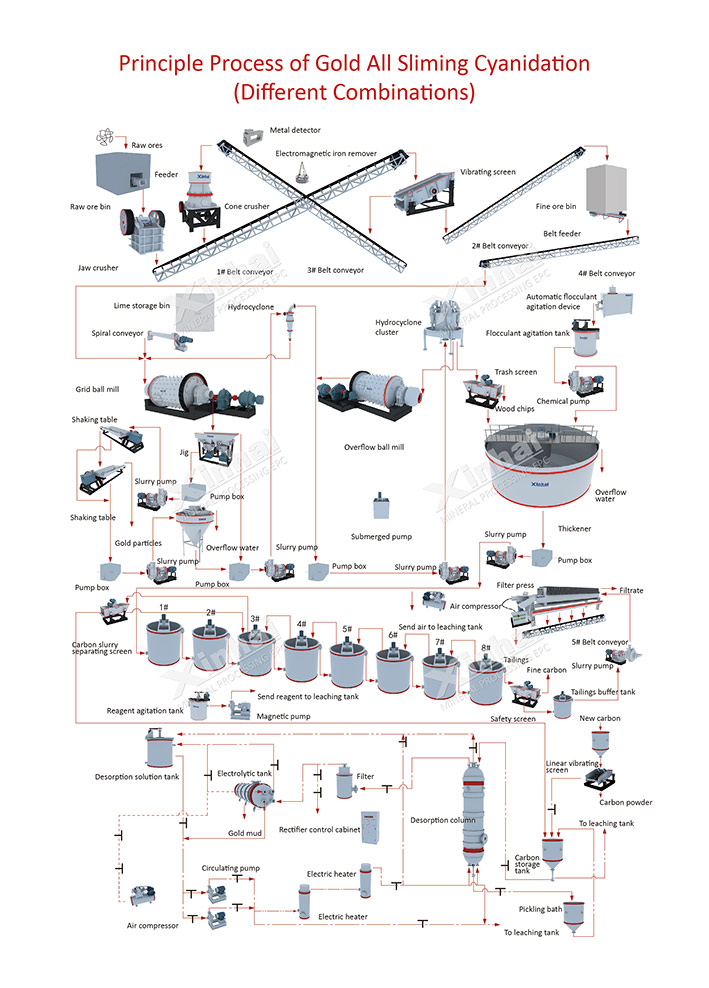

Gold extraction kicks off with digging. Ore gets trucked to a plant. First, machines smash and grind it into bits, like turning rocks to dust. This frees the gold. Then, methods like gravity or flotation grab the gold-heavy stuff. Chemicals, usually cyanide, dissolve the gold next. Finally, you pull the gold out with tricks like precipitation or smelting. Every step’s gotta be spot-on. A mine in Peru might chew through 12,000t/d for a few ounces of gold. Xinhai Mining handles it all—testing ore, building plants, boosting gold haul.

There’s a few ways to snag gold from ore. Cyanidation uses cyanide to melt gold out. Carbon-in-pulp grabs gold with activated carbon. The Merrill-Crowe method uses zinc to settle gold. New ideas, like bioleaching or thiosulfate, are kinder to nature. The ore and budget pick the method. A mine in Mongolia might use cyanidation but trap chemicals to avoid spills. Xinhai Mining tweaks these methods, using stuff like closed-loop systems to cut waste and keep things earth-friendly.

Safety’s huge in underground gold mines. Regular checks catch risks like shaky rocks or bad air. Emergency plans cover fires or floods. Workers train to spot trouble and wear gear like hard hats and masks. Tech, like gas sensors or proximity alarms, stops accidents. A mine in Australia once dodged a gas leak thanks to quick sensors—pretty cool, right? Xinhai Mining builds safety into every step, using audits and global standards like ISO 45001 to keep workers and gear safe.

Gold mining can rough up the environment. Waste, called tailings, might dirty rivers. Clearing land kills forests or animal homes. Machines also spit out carbon emissions. But there’s hope. Tailings dams lock waste away. Water plants clean runoff. Replanting, like a mine in Brazil turning a pit into woods, helps. Solar power cuts emissions too. Xinhai Mining pushes green fixes, like cutting waste or restoring land, so mines meet rules and do good by nature.

Gold mining’s getting smarter. Robots and AI make mines safer and quicker. Green tech, like electric trucks, shrinks pollution. Recycling gold from old phones is growing too. A mine in Sweden uses bots to sort ore, saving power. These tricks cut costs and help the planet. Xinhai Mining’s on top of it, building projects that use these ideas to stay strong and green for the long haul.

Responsible gold mining means balancing cash with care for people and nature. Talking to locals builds trust. Clear reports show what’s happening. Global rules keep things fair. A mine in Ghana hired locals and funded a school, which felt like a win for everyone. It’s not always smooth, but it’s worth it. Xinhai Mining pushes these practices, offering services that keep mines safe, smart, and kind to the earth, helping clients hit high standards.

Open-pit mining digs from the top for shallow gold. Underground mining uses tunnels for deep deposits. Open-pit’s cheaper but rough on land. Underground needs more setup but keeps the surface nicer.

Miners crush ore into bits. Chemicals like cyanide melt the gold. Then, methods like precipitation or carbon pull it out. It depends on the ore and tools.

Big worries are cave-ins, gas leaks, and broken machines. Training, gear, and tech like sensors keep workers safe.

It can dirty water, wreck land, and hurt animals. Tailings dams, water cleanup, and replanting cut the damage.

Xinhai Mining offers full EPC services—mining, ore processing, waste handling, and planning. They make custom plans for efficient, green gold mining.

Xinhai Mining’s a leader in gold mining worldwide. We cover everything—exploring, digging, processing, and mines operations. Our EPC solutions fit open-pit and underground mines, with skills in ore processing, waste control, and green practices. In Africa, we boosted a mine’s gold output by 12% with better gear. We focus on new ideas and happy clients, delivering projects that save cash and dodge risks. Drop us a line to see how Xinhai Mining can help your gold mining dreams with solid, custom services.

Xinhai Mining — Your Trusted EPC Partner in Gold Mining