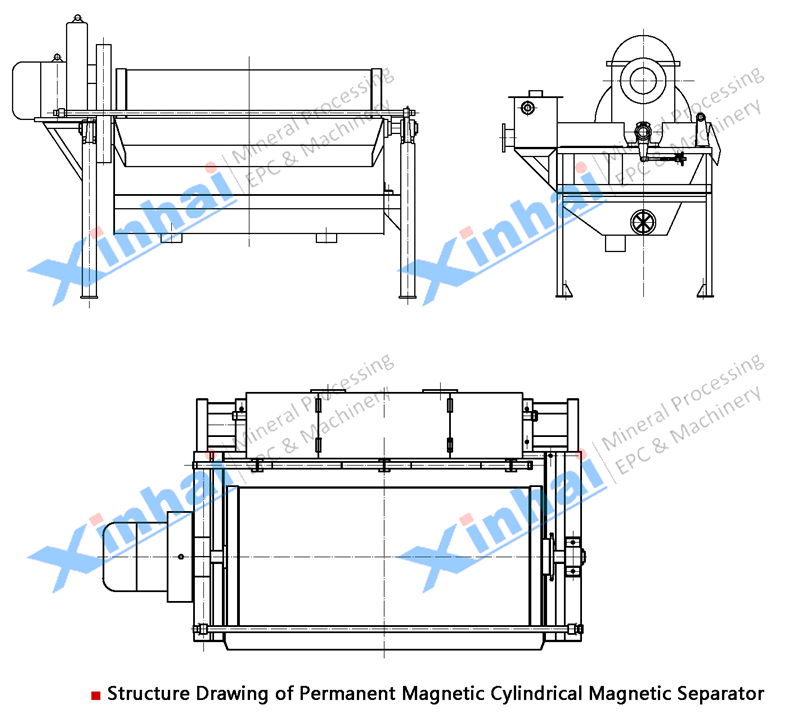

A wet permanent magnet magnetic separation equipment commonly used in the separation of strong magnetic minerals. 【Processing capacity】: 24t/h-240t/h 【Scope of application】: The permanent magnet drum type magnetic separator can be used for pre-selection, rough selection, selection, etc. The selected particle size range is 2~10mm.

The magnetic system adopts NdFeB magnets with high magnetic energy product and high coercivity, with high magnetic field strength, and the 8-year demagnetization rate does not exceed 5%;

The large-envelope magnetic system with gradual field strength and smooth transition increases the length of the separation zone and the number of magnetic flips, and realizes the efficient separation of magnetic minerals and non-(weak) magnetic minerals;

The magnetic system package is made of non-magnetic stainless steel to ensure that the magnet does not fall off;

According to different uses and sorting conditions, each series of magnetic separators have different magnetic system designs and tank structures;

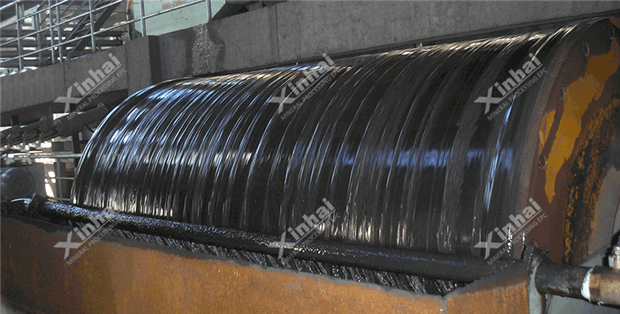

The cylinder is made of non-magnetic stainless steel and covered with wear-resistant rubber, and the service life of the cylinder is significantly improved;

The permanent magnet drum has strong adaptability to production, and can withstand large fluctuations in ore feeding amount, ore feeding granularity and pulp concentration;

Superior beneficiation index of high grade and high recovery rate can be obtained at the same time;

Each series of magnetic separators can be used together, or one of the series can be used alone, all of which can obtain excellent beneficiation indicators;

The tank structure is semi-countercurrent, and can also be made into a downstream tank according to the sorting conditions and user requirements.

Permanent magnetic drum separators have 3 kinds including downstream type, counter flow type and semi- counter flow type according to the difference of base structures.

Downstream type permanent magnetic drum separator: slurry flows in the same direction with the drum.

Counter flow type permanent magnetic drum separator: slurry flows over against the drum, which create great conditions for cleaning of non magnetic ores. The non magnetic ores approach the clean surface of the drum and the magnetic ores can be absorbed in the strongest magnetic field.

Semi-counter flow type permanent magnetic drum separator: slurry is fed into the cavity from the bottom of the drum, and the magnetic ores fall into the concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum.

| Model & Spec. | CTBY1018 | CTBY1024 | CTBY1030 | CTBY1218 | CTBY1224 | CTBY1230 |

| Diameter of Cylinder (mm) | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 |

| Length of Cylinder (mm) | 1800 | 2400 | 3000 | 1800 | 2400 | 3000 |

| Surface Magnetic Density (mt) | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 |

| Rotating Speed of Cylinder (r/min) | 23 | 23 | 23 | 20 | 20 | 20 |

| Capacity of Dry Ore (t/h) | 42 ~65 | 53 ~86 | 82~124 | 58 ~97 | 71~120 | 103~158 |

| Feed Size (mm) | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 |

| Slurry Density (%) | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 |

| Motor Power (kW) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Total Weight (t) | 5.2 | 6.4 | 7.1 | 6.7 | 7.2 | 8.9 |

| Equipment Length (mm) | 3160 | 3790 | 4460 | 3380 | 4190 | 4770 |

| Equipment Width (mm) | 2250 | 2250 | 2250 | 2460 | 2460 | 2460 |

| Equipment Height (mm) | 1750 | 1750 | 1750 | 2000 | 2000 | 2000 |

A magnetite dressing plant adopts Xinhai permanent magnet drum type magnetic separator. The magnetic separator equipment has different magnetic system design and tank structure, which can better solve the consideration of multi-ore composition and use before the dressing plant. At the same time, it has strong adaptability to production, and can be used in combination or alone, which can better obtain excellent beneficiation indicators.