If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

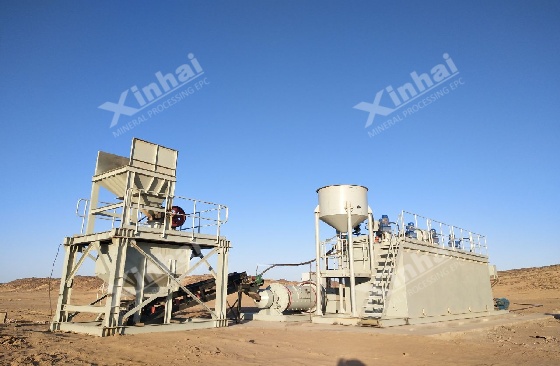

Modular gold processing plants have transformed the mining world, providing flexible, budget-friendly, and effective ways to extract minerals. These plants, built from pre-made sections, are a smart choice for miners looking to save money without losing quality. They’re crafted with cutting-edge design methods, shipped to sites, and set up quickly.

Picture a small mining operation in remote Australia. Instead of spending years building a huge facility, a modular plant arrives in pre-built chunks. It’s assembled in weeks, not months, and can process anywhere from 5t/d to 1200t/d. This range suits tiny startups or big players alike. The compact setup, paired with clever engineering, delivers results like large-scale plants but without the massive costs or logistical headaches.

Xinhai Mining, a leader in this space, customizes these plants to fit specific needs. Their engineers tweak each module to match the ore’s unique traits, boosting gold recovery and keeping downtime low. For example, a gold mine in Ghana used Xinhai’s modular system to hit 95% recovery rates on tricky ore—pretty impressive for a setup that didn’t break the bank.

Traditional gold plants demand heavy groundwork, long build times, and deep pockets. Think of a massive facility in Nevada, needing years of construction and millions in upfront costs. Modular systems, though, are pre-built off-site. They arrive ready to go, needing only basic site prep.

Xinhai Mining employs skilled engineers who design both modular and fixed plants. This flexibility lets them cater to different project needs. A client in Peru, for instance, chose a modular setup for a short-term project. When the ore ran low, they moved the plant to a new site in days—a feat impossible with traditional setups.

Traditional plants, once built, are stuck in place. Modular ones, however, can grow or move. This adaptability suits mines with scattered or short-lived ore deposits, like those in Mongolia’s steppes, where relocating equipment is often necessary.

Suppliers like Xinhai Mining are crucial for bringing high-tech solutions to miners while cutting risks. They don’t just sell gear—they offer full packages, from lab tests to on-site support. Imagine a junior miner in Tanzania: Xinhai runs tests on their ore, designs a custom plant, installs it, and trains the team. This all-in-one service ensures smooth operations.

Xinhai’s approach stands out. They guide clients from initial ore analysis to final startup, ensuring top efficiency. For a greenfield project in Zambia, they delivered a modular plant that was up and running in under two months, saving the client millions compared to a traditional build.

Modular systems shine by saving time, energy, and labor. They’re built in factories, so quality is consistent. A mine in Canada, for example, used a modular plant to cut installation time from 18 months to just 3. This speed means faster profits.

With capacities from 5t/d to 1200t/d, each module is tailored to handle tough ores. A small mine in Brazil dealt with coarse gold particles. Xinhai customized a module with a special circuit, boosting output by 20%. Honestly, it’s hard not to be impressed by how these systems adapt.

Plus, modular plants include smart monitoring tools. Operators can check performance on their phones, spotting issues fast. This tech helped a South African mine catch a pump failure early, avoiding days of downtime. Less downtime, lower costs—what’s not to like?

Innovation drives modular gold processing plant suppliers. Automation, eco-friendly chemicals, and precise testing make these plants stand out. Xinhai, for instance, runs detailed lab tests to mimic real-world conditions. In a 2023 project in Chile, their tests ensured a plant hit 98% gold recovery before it was even built.

Crushing and screening modules are game-changers too. They ensure the ore is just the right size for processing, which boosts efficiency. A mine in Russia used Xinhai’s modular crushing system and saw a 15% jump in recovery rates thanks to better feed prep.

Mobile modular plants add another layer of cool tech. These portable setups, often called mobile mining plants, are perfect for small or scattered deposits. A miner in Mali used one to process 50t/d of ore, moving it between three sites in a year. That kind of flexibility is a lifesaver for remote operations.

Remote mines face tough challenges: no roads, high shipping costs, and few workers. Modular plants tackle these head-on. Their small size means less land disruption. A mine in Alaska, for instance, set up a modular plant with minimal clearing, keeping environmental impact low.

For small-scale miners, like artisanal groups in Colombia, modular systems are a game-changer. These folks often work rich deposits but lack cash for big setups. A modular plant, designed for small, scattered mines, lets them process gold efficiently. Xinhai’s smallest 5t/d unit helped a co-op in Peru double their output without needing a bank loan.

Scalability is another perk. Start small, then add modules as the mine grows. A junior miner in Australia began with a 10t/d plant. Two years later, they scaled to 50t/d without halting production. That kind of growth is a dream for small operations.

Modular plants save money big time. Lower upfront costs, quicker returns, and cheaper operations make them a no-brainer. A mine in Mexico slashed its startup budget by 30% using a modular setup. Plus, the fast setup meant they were earning revenue in months, not years.

Environmentally, these plants are kinder to the planet. Smaller footprints mean less deforestation. Factory-built modules cut waste. Energy-saving designs lower emissions, and water recycling reduces freshwater use. A project in Mongolia used Xinhai’s water-saving system, cutting usage by 40% while meeting strict environmental rules.

Mobile gold and diamond washing plants with jig concentrators are another win. These use gravity to separate minerals, reducing chemical needs. A mine in Sierra Leone used one to recover 90% of its gold with minimal environmental impact. It’s hard to argue with results like that.

Picking a supplier isn’t just about gear—it’s about trust, expertise, and support. Ask: Do they test ore thoroughly? Have they built plants in similar conditions? Are their modules safe and compliant? Can they scale up later?

Xinhai Mining checks all these boxes. They’ve built plants in over 50 countries, from icy Canada to scorching Sudan. Their lab tests ensure the plant fits the ore perfectly. Plus, they offer ongoing support, like helping a mine in Zimbabwe fix a glitch remotely. That kind of service makes them a top pick among modular gold processing plant suppliers.

Q1: What is a modular gold processing plant?

A: It’s a pre-built system made of movable units. These handle crushing, grinding, or leaching based on the ore. They’re quick to set up and need little infrastructure.

Q2: How do I know if my operation is suitable for a modular system?

A: Got a remote site, tricky ore, or tight budget? Modular plants work great in those cases, offering flexibility and lower costs.

Q3: Can I expand my existing setup using additional modules?

A: Absolutely. You can add modules as your mine grows. It’s seamless and keeps operations running.

Q4: Why choose Xinhai Mining as your supplier?

A: Xinhai offers full support, from ore testing to plant startup. They customize for your ore, focus on eco-friendly designs, and ensure scalability. Their decades of global experience make them a solid choice.