If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

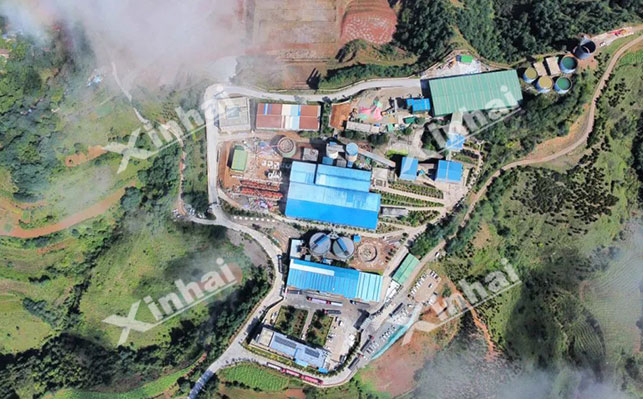

A mining company originally operated two mature 900 t/d silver-lead-zinc-gold polymetallic ore processing lines with stable output. However, due to growing market demand and the company's development strategy, the client aimed to expand production capacity by adding a new 1,500 t/d processing line adjacent to the existing plant.

Xinhai Mining took over the project in 2024, providing a full suite of EPCM+O services, including process design, engineering design, equipment manufacturing, civil construction, plant installation, project management, and quality control.

The project showcased the "Xinhai Speed" — from project kickoff to commissioning, it took only 198 days. To maximize metal recovery, Xinhai developed a highly targeted beneficiation process, which was well received by the client. Below is an overview of the process flow and key highlights.

The ore contains valuable metals such as silver, lead, zinc, and gold. Based on the client’s target capacity of 1,500 t/d (with provisions for future expansion to 1,800 t/d), Xinhai adopted a gravity separation–flotation combined process. The specific steps are as follows:

(1) Crushing and Screening

Process: A three-stage closed-circuit crushing system (jaw crusher + cone crusher + vibrating screen) reduces the ore size to below 15 mm.

Highlight: An intelligent fine ore disposal system was added to manage particles smaller than 15 mm. The #5 conveyor belt was upgraded, and a new belt line was installed, linking to the newly constructed #3 fine ore bin. This bin serves as a "buffer reservoir" for the new grinding circuit, significantly improving feed stability and system flexibility.

(2) Grinding and Gravity Separation

Grinding: A third grinding circuit was constructed on the west side of the grinding plant. The key equipment includes an MQG3645 grid-type ball mill paired with a set of φ350×8 hydrocyclones, forming a closed-circuit grinding system.

Fineness: The grinding fineness is strictly controlled, with -200 mesh (i.e., -0.074 mm) accounting for 60%–65%, ensuring optimal conditions for subsequent flotation.

Gold Recovery via Gravity: A gravity separator and shaking table are integrated into the grinding circuit. By utilizing the high specific gravity of gold, part of the gold is recovered at an early stage, significantly improving the overall gold recovery rate.

(3) Flotation Separation

A preferential flotation process is adopted, in which lead (along with silver as its associated mineral) is recovered first, followed by zinc.

Lead Flotation: The flotation process consists of one roughing, three scavenging, and three cleaning stages. This ensures a lead concentrate grade of ≥45% and a recovery rate of >90%. Silver is primarily concentrated in the lead concentrate. The reagent system was optimized accordingly to enhance selectivity and recovery.

Zinc Flotation: The tailings from lead flotation undergo one roughing, four scavenging, and three cleaning stages, ensuring a zinc concentrate grade of ≥50% and a recovery rate of >85%.

(4) Concentrate Dewatering

Lead Concentrate: Two existing φ20m efficiency thickeners are used for primary thickening, followed by a newly installed 36 m² ceramic filter for final dewatering. The ceramic filter delivers high efficiency and produces a low-moisture filter cake.

Zinc Concentrate: A new φ18m thickener was installed to the east of the original thickener for primary thickening, along with a 36 m² ceramic filter for final dewatering.

Result: The final concentrate moisture content is controlled at ≤12%, meeting transportation and marketing requirements. The overall water recycling rate is high, demonstrating the project's commitment to energy conservation and environmental protection.

The project was completed in just 198 days—30% faster than the average timeline for comparable projects.

The actual ore processing capacity stabilized at 1,800 t/d, exceeding the planned 1,500 t/d by 20%.

The implementation of an intelligent waste disposal system and optimized process flowsheet reduced waste rock generation by 8%, resulting in annual transportation cost savings of several million yuan.

Conclusion

As mineral resources become increasingly scarce, designing mineral processing flows that ensure both environmental protection and economic benefits becomes crucial. For polymetallic projects like this one, comprehensive recovery of multiple valuable metals is key to avoiding resource loss.

With nearly 30 years of experience and thousands of mineral processing projects completed, Xinhai Mining has developed into a professional, reliable, and efficient team. If you encounter any challenges in mineral processing, contact us—we will tailor a scientific and practical project solution to ensure the success of your operation.