A new type of self-developed high-efficiency thickener. 【Processing capacity】: 5-1400t/d 【Scope of application】: It is suitable for occasions with large processing capacity and low product concentration. It is mainly used for the concentration of concentrates in concentrators and the dehydration of tailings. It can also be widely used in the concentration and purification of liquids containing solid particles in chemical industry, building materials, and water source and sewage treatment industries.

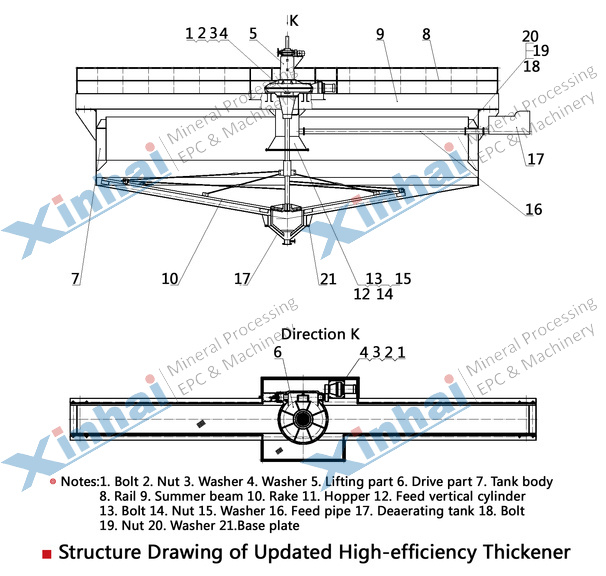

The high-efficiency reformed thickener equipment developed by Xinhai has an additional degassing tank, which can eliminate solid particles from adhering to the air bubbles and settle like a "parachute";

Its feeding pipe is designed under the liquid level to prevent the gas from being brought into the mine;

The feeding sleeve moves down and is equipped with a receiving tray, so that the fed ore slurry falls evenly and smoothly, effectively preventing the phenomenon of turning over caused by the residual pressure of the ore;

The internal overflow weir is added to make the material flow according to regulations, prevent the phenomenon of "short circuit", and greatly increase the sedimentation area;

The overflow weir of Xinhai high-efficiency thickener is changed to zigzag to improve the local suction phenomenon caused by the uneven overflow weir;

Change the horizontal feeding of the traditional thickener to inclined feeding, which fundamentally eliminates the problem of feeding blockage;

Equipped with a slow flow device to slow down the rising speed of the material water flow, so that the overflow water is more uniform and the turbidity is lower.

The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow dam.

| Model | Tank Diameter (mm) | Tank Depth (mm) | Subsidence Area (m2) | Capacity (t/d) | Motor Model | Motor Power (kW) | Steel Tank Weight (kg) | Weight (kg) |

| NZSG-2.5 | 2500 | 1850 | 4.9 | 5 ~22.4 | Y90L-6 | 1.1 | 1000 | 2225 |

| NZSG-3A | 3000 | 1800 | 7 | 5 ~23.3 | Y100L-6 | 1.5 | 1664 | 3168 |

| NZSG-3 | 3600 | 1800 | 10.2 | 5 ~28.5 | Y100L-6 | 1.5 | 2097 | 3680 |

| NZSG-5 | 5000 | 2956 | 16 | 16 ~90 | Y90L-4 | 1.5 | 5160 | 8031 |

| NZSG-6 | 6000 | 2956 | 28.3 | 98 | Y90L-4 | 1.5 | 5769 | 9200 |

| NZSG-7 | 7000 | 3000 | 38.5 | 140 | Y112M-6 | 2.2 | 8800 | 13862 |

| NZSG-8 | 8000 | 3318 | 50.2 | 185 | Y132S-6 | 3 | 12966 | 19158 |

| NZSG-9 | 9000 | 3376 | 63 | 210 | Y132S-6 | 3 | 15418 | 21733 |

| NZSG-12 | 12000 | 3600 | 113 | 370 | Y132S-6 | 3 | 25589 | 34823 |

| NZSG-15 | 15000 | 3600 | 176 | 580 | Y132S-4 | 5.5 | 35800 | 54315 |

| NZSG-18 | 18000 | 4400 | 255 | 960 | YCT200-4B | 7.5 | 52485 | 73588 |

| NZSG-20 | 20000 | 4400 | 315 | 1400 | YCT200-4B | 7.5 | 59365 | 76312 |

During the enrichment process of a gold mine, it was found that the concentration of the bottom flow in the discharge was not high, and the solid-liquid separation was not obvious, so several high-efficiency reformed thickeners were added. Xinhai's high-efficiency reformed thickener has changed the rake tooth linearity from oblique type to curve type, which increases the concentration of ore discharge underflow and increases the processing capacity. Liquid separation is more obvious.