If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Gold’s been a big deal forever—think kings, pirates, and treasure chests. But getting it out of hard rock? That’s a whole different story. Unlike sifting through riverbeds for shiny nuggets (that’s placer mining), hard rock gold mining means pulling tiny gold specks from solid stone, stuff you can’t even see.

This guide breaks down every step of hard rock gold mining, from sniffing out where the gold hides to turning it into bars you’d see in a bank.

Finding gold is like hunting for buried treasure. It’s part science, part guesswork, and a sprinkle of luck.

Geologists start by poking around, studying rocks and land shapes like detectives on a case. They use tricks like magnetic surveys to spot minerals that act like tiny magnets. Or they try electromagnetic surveys to find stuff that conducts electricity underground. They also grab samples of dirt, rocks, and water to check for gold traces—kind of like tasting soup to see what’s in it. Then comes drilling. They bore deep holes to pull out rock cores, which tell them where the gold is, how far down, and how much might be there.

Once they spot a good deposit, it’s time to figure out if it’s worth digging. A feasibility study looks at the money side—how much it’ll cost, what the profits might be, and any risks. It also checks how the mine might affect nature or nearby towns. Engineers then map out the mine, deciding where to put tunnels or big open pits. Getting permits from the government is a big hurdle; it can take ages to get all the paperwork sorted.

Building a mine is like setting up a little city. You need roads for trucks to carry ore. Power lines to keep machines humming. Water pipes for drinking and washing rocks. Plus, phone and internet lines to stay in touch. Nearby, they build plants to process the ore later. It’s a huge job, but it gets everything ready for the real work.

With the mine built, it’s time to crack open the earth and grab that gold-filled rock.

First, miners use big drills to make holes in the rock face. They stuff those holes with explosives, then set off a controlled blast—boom! The rock breaks into smaller pieces, ready to move. Safety’s a big deal here. One slip-up could cause trouble, so they follow strict rules, like checking the blast area twice to keep workers safe.

After blasting, the broken rock, or “muck,” gets scooped up. In open-pit mines, huge shovels load it into giant trucks—some hold 150 tons! Those trucks haul it to crushers or the plant. Underground, special machines called load-haul-dumps grab the muck and put it on mine cars or belts. Then it’s lifted to the surface through shafts. It’s gritty, dusty work, but it moves the gold closer to daylight.

Hard rock gold mining comes in two main styles:

Open-Pit Mining: Best for gold close to the surface. It’s quicker and cheaper but digs up a lot of dirt, leaving big marks on the land.

Underground Mining: For deeper gold. It’s tougher and costs more, needing fans for air and supports to keep tunnels safe. But it doesn’t mess up the surface as much. Methods like stoping or room-and-pillar get used, depending on the rock setup.

The big rock chunks from the mine need to be smashed and ground to free the tiny gold bits locked inside.

Huge ore pieces go into primary crushers, like jaw or gyratory models. These monsters break the rock into smaller bits, usually under 200 mm. Xinhai Mining makes some tough crushers that keep this step running like clockwork.

Next, the ore hits smaller crushers, often cone crushers. These shrink it even more, down to about 25 mm, so it’s ready for grinding.

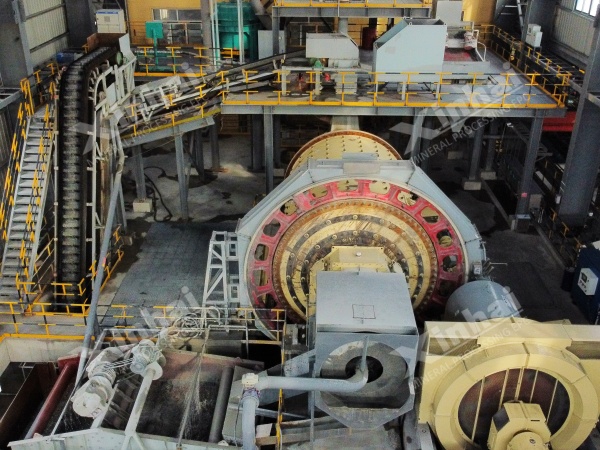

Grinding’s where things get serious. The crushed ore mixes with water to make a soupy slurry. This goes into big mills, like Semi-Autogenous Grinding (SAG) mills or ball mills. Inside, steel balls and water tumble with the ore, smashing it into a super-fine powder, smaller than 0.1 mm. This frees the gold from the rock, making it easier to grab later.

After grinding, the slurry runs through hydrocyclones or screens to sort by size. Chunks that are too big go back for more grinding. This makes sure everything’s fine enough for the gold-pulling step.

Now it’s time to separate the gold from all that ground-up rock. This part uses some clever tricks.

Gold’s heavy, so gravity’s a great tool. Machines like jigs, spirals, or shaking tables grab bigger gold bits early. It’s a clean, simple way to nab some gold before the tougher steps.

If gold’s stuck in sulfide minerals, flotation’s the answer. Chemicals make the gold-carrying sulfides stick to air bubbles. The bubbles float up, carrying the gold, while the junk sinks. The frothy top gets skimmed off, leaving a gold-rich mix.

Cyanide leaching is the top way to get gold. Here’s the breakdown:

Carbon-in-Pulp (CIP) / Carbon-in-Leach (CIL): The slurry mixes with cyanide to dissolve gold. Activated carbon grabs the gold, either during (CIL) or after (CIP) dissolving. It works great but needs tight safety rules since cyanide’s dangerous.

Heap Leaching: For low-grade ore, miners stack it on leak-proof pads and drip cyanide over it. The gold dissolves into a solution. It’s cheaper but needs careful checks to avoid leaks.

Counter-current Decantation (CCD): If CIP/CIL isn’t used, thickeners wash the gold solution from the leftover muck, making sure no gold gets wasted.

At this point, the gold’s either in a solution or stuck to carbon. These last steps turn it into pure bars.

Gold gets pulled off the carbon with hot, strong cyanide solutions, around 150°C. This makes a gold-heavy liquid called pregnant eluate. The carbon gets heated up and reused, which saves cash. Xinhai Mining’s equipment makes this step super smooth.

The eluate goes into electrowinning cells. An electric current pulls the gold out, forming a rough sludge on the cathodes, usually over 90% pure.

The sludge gets mixed with things like borax and heated in a furnace. Impurities burn off, and the melted gold pours into molds, making Dore bars—about 90% pure. These go to refineries to hit 99.99% purity or better. It’s pretty cool to see muddy sludge turn into shiny gold!

| Category | Equipment Name |

|---|---|

| Mining & Ore Extraction | Drilling Rigs |

| Explosives | |

| Excavators & Shovels | |

| Haul Trucks | |

| LHD (Load-Haul-Dump) Machines | |

| Mine Hoists & Conveyors | |

| Ore Processing & Comminution | Primary Crushers (Jaw, Gyratory) |

| Secondary & Tertiary Crushers (Cone) | |

| SAG (Semi-Autogenous Grinding) Mills | |

| Ball Mills | |

| Hydrocyclones & Screens | |

| Gravity Concentrators (Jigs, Spirals, Shaking Tables) | |

| Flotation Cells | |

| Leach Tanks (CIL/CIP Vessels) | |

| Activated Carbon Adsorption Systems | |

| Heap Leach Pads | |

| Sprinkler Systems | |

| Thickeners (in CCD Circuit) | |

| Refining & Smelting | Elution Columns / Vessels |

| Electrowinning Cells | |

| Smelting Furnaces | |

| Molds | |

| Environmental & Auxiliary Equipment | Tailings Storage Facilities (TSFs) / Dry Stack Filters |

| Water Treatment Plants | |

| Ventilation Systems (Underground) | |

| Dust Collection Systems |

Hard rock gold mining is a giant puzzle, mixing science, engineering, and care for nature. From chasing gold veins to pouring shiny bars, every step’s a challenge. As gold stays popular, miners are using new tools and greener ways to do it right. Curious for more? Check out Xinhai Mining’s site for awesome tips and gear!