If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

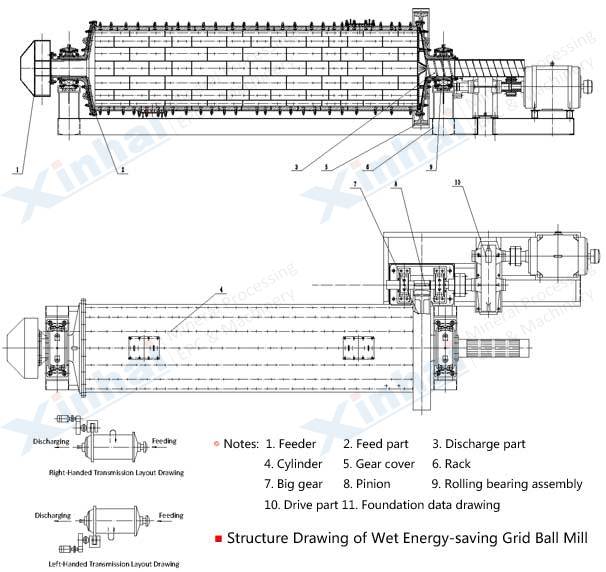

Ball mills are fine grinders, have horizontal ball mill and vertical ball mill, their cylinders are partially filled with steel balls, manganese balls, or ceramic balls. The rotating cylinder creates friction and impact that grinds the material into fine powder. The internal machinery of the ball mill grinds the material into powder and continues to rotate if extremely high precision and precision is required. Additionally, the feed of the ball mill contains grinding balls and in order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possible.

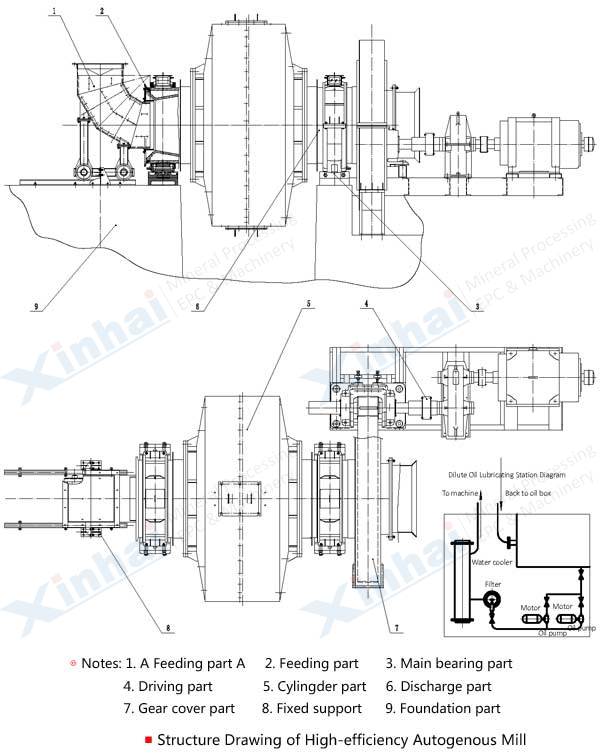

AG/SAG is short for autogenous mill and semi-autogenous mill, it combines with two functions of crushing and grinding, uses the ground material itself as the grinding media, through the mutual impact and grinding action to gradually reduce the material size. SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20%. Sometimes, in order to improve the processing capacity of the mill, a small amount of steel balls be added appropriately, usually occupying 2-3% of the volume of the mill (that is semi-autogenous grinding).

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s crushing ratio is smaller. The feed size is usually between 20-30mm and the product size is 0-3mm.

Ball mills serve as precision grinding equipment. They function by rotating a drum filled with grinding media. These media often consist of steel or ceramic balls. As the drum turns, friction and abrasion forces act between the grinding balls and the ore particles. This process gradually breaks the material down. The result is a finer particle size distribution.

The operating principle of a SAG mill is somewhat similar to a ball mill. But there’s one major distinction: a SAG mill uses the ore itself as part of the grinding media. Inside the rotating cylinder, larger rocks tumble and collide with other material. Through continuous impact and attrition, the ore gradually crushes and refines itself. This self-grinding effect allows the SAG mill to handle coarser feed directly. It reduces the need for extra grinding media.

In a SAG mill, the grinding media includes a mix of large, hard rocks drawn from the ore. This leads to stronger impact forces during operation. On the other hand, ball mills are loaded with manufactured steel balls. These provide more controlled and uniform impacts. This helps achieve consistent particle size reduction.

SAG mills usually draw more power. One reason is they perform both crushing and grinding in a single unit. Still, their ability to process more material per hour can make up for higher energy use. This is especially true in large-scale mining operations where throughput is critical.

Since SAG mills accept coarse feed directly from primary crushers, they often remove the need for secondary crushing. That simplifies the comminution circuit. Even though their power draw is high, the overall energy used per tonne can be lower. This is due to the elimination of an entire processing stage.

Efficiency isn’t the same for every operation. It depends on rock hardness, liner shape, mill speed, how full the mill is, and how well classification works. In SAG mills, wrong media loading or a poorly set classifier can really hurt performance. For example, if the ore is too hard or too soft, you might not get the right particle breakdown.

SAG mills excel with hard ores. They are often used as a first-stage grinder for copper or gold ore. Ball mills, meanwhile, are better for finishing grinding steps. They work well with softer ores or when you need a very fine product.

SAG mills adapt more easily to changing ore properties. They can take in lumpy feed and still operate. Ball mills need a more consistent feed size. But they do offer better control over the final product’s fineness.

SAG mills are big and robust. But they also need more maintenance planning. Think about liner changes, bearing checks, and discharge grate inspections. Ball mills have simpler mechanics. You’ll change liners and balls often, but the work is usually quicker.

SAG mills take up more floor space. They have larger diameters to handle big rocks. Ball mills are more compact. That makes them easier to fit into existing plants or modular setups.

Installing a SAG mill isn’t a small job. It needs a strong foundation, big bearings, and often discharge screens or pebble ports. Ball mill installation is typically simpler. Many use overflow discharge systems that are easier to set up.

Both mill types need solid foundations. But SAG mills create more vibration and dynamic loads. That means deeper concrete bases and more steel support. You don’t want any movement once it’s running.

SAG mills come with higher upfront costs. The equipment is bigger. You also need more infrastructure around it. Ball mills are more affordable initially. They are a common choice for smaller plants or those on a tight budget.

A SAG mill might save money by cutting out a crusher stage. But its daily running cost can be high. Ball mills usually have lower operating costs. They use less power per tonne in fine grinding and their parts are easier to replace.

Ball mill liners are cheaper and last a decent amount of time. In a SAG mill, wear parts face more abuse. Liners, grates, and lifters need frequent inspection. Replacement isn’t just costly—it causes downtime.

SAG mills are often the first step in copper and gold plants. For instance, a site might use a 10m SAG mill to process 2000 tonnes per hour. Ball mills then take the discharge for further grinding. In iron ore, ball mills often prepare pellet feed. They grind it down to a very fine size.

A typical flowsheet goes: SAG mill → ball mill → flotation. The SAG mill breaks down the big bits. The ball mill finishes the job. This combo is common in modern mineral processing.

Both mills work with classifiers. Cyclones help control particle size. From there, slurry goes to flotation or leaching. It’s all about getting the right size for the next step.

You can tweak a ball mill’s speed—stay around 70-80% of critical speed. Also, pick the right liner profile. Keep an eye on the charge volume. And use a good classifier. These steps help maximize output.

Monitor bearing temperatures—a lot of SAG mills have two sensors per bearing. If it gets too hot, the system can alarm or shut down. Also, adjust pebble ports to recycle oversize. This improves efficiency when ore hardness changes.

Some mines combine equipment. For example, they use an HPGR before a ball mill. Or they pair a SAG mill with a secondary crusher. This balances energy use and cost. It’s about finding what works for your ore body.

Q: What’s a key difference between SAG mill vs ball mill?

The main difference is grinding media. A SAG mill uses the ore itself to grind. A ball mill uses steel or ceramic balls.

Q: Which has higher throughput?

Usually, SAG mills do. They’re built for volume. A large SAG mill can process thousands of tonnes per hour. That’s because it takes feed right from the crusher.

Q: Are both suitable for all ores?

Not exactly. SAG mills prefer harder ores—like copper or gold. Ball mills are more flexible with softer material or when you need a super-fine product.