If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Gravity separation technology stays a solid, budget-friendly choice for processing iron ore. It uses natural density differences, cutting down on costly chemicals. For deposits rich in hematite, magnetite, or chunky particles, gravity methods offer steady recovery, cheaper running costs, and easier upkeep than chemical-heavy options. Think of it like sorting heavy rocks from light ones—simple but effective.

Certain ore traits make gravity separation shine. Big density gaps between iron minerals and waste materials are key. You also need ore with coarse or medium-sized particles that break free easily, plus low levels of sticky clay or slime. When these conditions align, gravity methods churn out high-quality concentrates without needing tons of grinding.

Using gravity-first setups slashes the need for chemicals and energy. This cuts costs and makes waste management simpler. A well-planned gravity circuit—with steps like staged cleaning, water reuse, and tailings reprocessing—keeps the environmental impact lower than systems relying heavily on flotation. It’s a practical way to stay green while keeping profits up.

Gravity separation works by letting heavier particles settle faster than lighter ones. Under controlled conditions—like steady water flow, shaking, or spinning—heavier iron bits separate from lighter waste. This creates layers that machines can split into valuable concentrate and leftover tailings. It’s like shaking a pan of sand and gold—the heavy stuff sinks.

Here’s a quick look at common gravity separation tools and when they’re handy:

Jigs: Great for rough, high-volume jobs. They handle coarse ore well, need little upkeep, and keep things simple.

Shaking tables: Perfect for precise work. They clean up complex or fine ore fractions with spot-on accuracy.

Spiral concentrators: Basic, low-power units. They’re best for steady processing of medium to fine ore with clear density differences.

Hydrocyclones: Not true gravity separators but super useful for sorting sizes and removing slimes, boosting gravity setups.

Centrifugal concentrators: Crank up the force to grab tiny particles that regular gravity struggles with.

Gravity separation does well with coarse to medium particles that have strong density differences. Magnetic separation is the go-to for magnetite-packed ores. Flotation works better for super fine particles or tricky chemical mixes. Smart plants mix all three: gravity grabs the chunky, dense stuff, magnetic pulls magnetite, and flotation tackles fines or tough waste. It’s a team effort for top results.

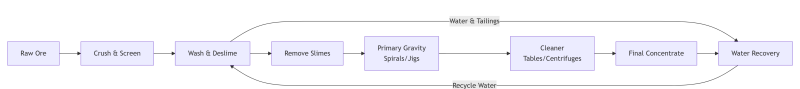

A solid gravity-based process for iron ore might go like this:

1. Crush and screen the ore. This creates size chunks that gravity machines can handle.

2. Wash and deslime. This clears out clays that mess up the separation.

3. Use spirals or jigs for the first pass. They snag most of the heavy iron minerals.

4. Clean the concentrate. Shaking tables or centrifugal units polish it to high quality.

5. Recycle water and reprocess tailings. This keeps waste low and efficiency high.

For coarse ore (bigger than 2 mm), heavy medium separation or jigs deliver strong output and recovery. Take a mine in Western Australia—jigs there hit 85% recovery on coarse hematite. For finer ore (0.1–2 mm), spirals and shaking tables strike a balance between speed and quality. Ultrafine tailings (under 0.1 mm) need centrifugal units or a touch of flotation to finish the job. Honestly, getting those tiny bits is always a bit of a hassle.

Good prep makes all the difference. Keeping feed sizes steady and slurry density just right boosts recovery. Simple steps like using scalping screens, hydrocyclones, or controlled grinding keep the circuit stable. For example, a Brazilian plant cut recirculating loads by 20% just by tightening size control before the spirals. It’s not flashy, but it works.

| Advantages | Limitations |

|---|---|

| Low operational cost | Reduced efficiency for ultrafine particles |

| Simple equipment design | Limited throughput for very fine ore |

| Energy-efficient processing | Requires proper feed preparation |

| Environmentally friendly (less chemical use) | Not effective for ores with minimal density contrast |

| Effective for medium to coarse iron ore | Hybrid methods may be needed for complex ores |

Every ore deposit is different. Without detailed data on mineral types and sizes, your gravity circuit might flop. Pilot tests and simulations are a must. For instance, a Chilean mine tweaked their jig setup after lab tests and hit 90% recovery. Skipping this step is like guessing your way through a maze.

Gravity separation technology sorts iron ore using density differences. It’s great for ores with free, chunky particles and low clay content, producing clean concentrates with minimal fuss.

Gravity relies on weight differences. Magnetic separation uses magnetic pull for magnetite. Flotation works with surface chemistry for fines. Each suits different ores and sizes, often combined for best results.

Yes, especially in hybrid setups. Gravity pulls coarse iron from low-grade ores economically. For complex or super fine ores, add magnetic or flotation steps to get the job done.

Spirals, jigs, and shaking tables are go-to tools. Hydrocyclones help with sizing, and centrifugal units tackle ultrafines. Pick based on ore size, volume, and target quality.

It cuts chemical use and energy needs. Water recycling and tailings reprocessing—like a Swedish mine reusing 80% of water—make gravity a solid choice for greener mining.

Gravity separation technology is a smart, green way to recover iron ore. Want a custom process that fits your deposit? Reach out to Xinhai Mining for expert design, testing, and equipment advice.