If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Depending on how the crystals look, how neat they’re packed, and where they pop up, graphite ore splits into three bunches: crystalline graphite, amorphous graphite, and vein graphite. When you’re cleaning and prepping graphite ore, grinding’s a must-do. The big headache? Keeping those jumbo flakes safe while the mill spins. Mix up the gear right, and you’re golden.

Hands down the star player—most wanted, most pricey.

Crystal Bits: Crystals bigger than 1 micrometer. Spot ’em easy, either bare-eyed or under a scope, looking all scaly and flat. Super tidy inside, real high crystallinity.

Ore Grade: Starts kinda skinny, maybe 3% to 10%. Rare fat pockets hit 20-plus. But toss it through beneficiation—flotation mostly—and bam, 94% to 99% pure carbon.

Industrial Worth: Sky-high. Floats like a dream, puffs up nice, conducts heat and juice like a champ. Perfect feed for fancy stuff—expanded graphite, bendy sheets, battery anodes, slick coatings.

Hangouts: Jixi, Liumao in Heilongjiang; Pingdu, Shandong; Xinghe, Inner Mongolia—China turf. Plus Madagascar, Sri Lanka.

Crystal Bits: Teeny crystals under 1 micrometer. Squint through a microscope, still a blurry clump. Dull shine, soft like dirt, feels almost muddy.

Ore Grade: Fat right outta the ground—60% to 80%, sometimes more. A quick hand-sort might do the trick.

Industrial Worth: Not as hot as flake. Tiny bits hate floating, tough to polish pure. Stays in simpler gigs—pencils, firebricks, mold coatings, basic carbon junk.

Hangouts: Lutang, Chenzhou in Hunan; Panshi, Jilin—China again.

Kinda oddball, not much around.

Crystal Bits: Fills cracks in solid hunks or stringy veins. Crystals big enough to eyeball, but jumbled every which way, packed tight.

How It Forms: Folks figure hot carbon goo—like old oil or gas—cooks inside rock splits.

Industrial Worth: Pure and zaps electricity good, but scarce digs and rough mining keep it niche. Mostly seals, top-shelf grease.

Hangouts: Sri Lanka, bits in the States, Canada.

This stage aims to break down the raw ore to a size where the graphite flakes begin to separate from the gangue.

Jaw Crusher: Used for the initial, primary crushing of large raw ore to a manageable size. It provides a coarse product for further processing.

Hammer Crusher: Another option for primary crushing, particularly effective for brittle materials.

This is the most critical stage where the protection of flake size is paramount. The equipment chosen here significantly impacts the final flake preservation rate.

Ball Mill: A widely used grinder. However, it can be detrimental to large flakes if not operated carefully. The impact and attrition from steel balls can easily break flakes. It is often used in circuits where the highest flake preservation is not the sole objective or for lower-value applications.

Rod Mill: Generally preferable to a ball mill for flake protection. The rods linearily contact the ore, providing a more gentle grinding action with less severe impact and more of a rolling/abrasion effect, which helps in selectively grinding the gangue without excessively breaking the flakes.

Vertical Roller Mill (VRM): An efficient alternative that uses pressure and shear forces between rollers and a table. It can be more energy-efficient and offer better control over particle size distribution, potentially leading to better flake preservation compared to traditional tumbling mills.

For the highest value flake graphite, more specialized equipment is employed.

Stirred Mill (or Attrition Mill): This is often considered an excellent choice for fine grinding while preserving flake structure. It uses a central stirrer that agitates small grinding media. The energy is imparted more uniformly through shear and attrition, which is less likely to cause the sharp impacts that shatter large flakes compared to ball mills.

Jet Mill (or Fluidized Bed Jet Mill): An ideal solution for the utmost protection of graphite flakes. It uses high-speed jets of air or steam to cause particles to collide with each other and break. This method is:

Autogenous: No grinding media to impact and break the flakes.

Cool: Prevents thermal damage to the graphite.

Precise: Allows for very tight control over the final product's top particle size.

The core principle is to match the grinding method to the crystal structure and the economic value of the final product. The goal is liberation, not destruction.

Objective: To liberate the graphite flakes from the gangue mineral matrix while maximizing the protection and yield of large and medium flakes, which are the most valuable.

Recommended Equipment & Flow:

A gentle, multi-stage approach is essential.

Primary Crushing:

Jaw Crusher: Standard for initial size reduction. It produces a coarse product for further processing with minimal fines generation.

Coarse/Liberation Grinding:

Rod Mill: Highly Recommended. The grinding action of a rod mill is a combination of impact and abrasion, but it operates with a "rolling" or "cascading" effect. The rods act like rolling pins, applying pressure that tends to break the ore along grain boundaries, effectively liberating the flake graphite with less shattering and over-grinding compared to a ball mill.

Vertical Roller Mill (VRM): An excellent alternative. It uses pressure and shear forces between rollers and a table, which is a gentler method for flake liberation than high-impact tumbling.

Fine/Regrinding of Concentrates:

Stirred Mill (Attrition Mill): Ideal for regrinding flotation concentrates to a finer product size without destroying the flakes. It uses a central stirrer to agitate small grinding media, imparting energy mainly through shear and attrition forces, which are less destructive than the high-impact forces in a ball mill.

Jet Mill (Fluidized Bed Jet Mill): The ultimate solution for protecting flake integrity. It uses high-speed jets of air or steam to cause particles to collide with each other. This autogenous grinding method involves no mechanical media, ensuring minimal mechanical damage and yielding graphite with excellent crystallinity and a high aspect ratio. It is often used for the final processing of high-value battery anode material.

Summary Strategy for Crystalline Graphite:

Jaw Crusher → Rod Mill / VRM → Multi-Stage Flotation → Stirred Mill / Jet Mill (for final product sizing). Avoid standard Ball Mills in critical stages as they are highly detrimental to flake size.

Objective: To efficiently liberate the microcrystalline graphite from the gangue. Since there are no large flakes to protect, the focus shifts to energy efficiency, cost-effectiveness, and achieving the desired liberation and fineness.

Recommended Equipment & Flow:

A simpler, more robust, and high-capacity circuit is sufficient.

Primary & Secondary Crushing:

Jaw Crusher + Hammer Crusher: This combination is very effective. Hammer crushers are excellent for brittle materials like amorphous graphite and can achieve significant size reduction in one stage.

Fine Grinding:

Ball Mill: The standard and most common choice. The concern about flake destruction is irrelevant. Ball mills are highly efficient at reducing the particle size of this microcrystalline material to the levels required for its typical applications (e.g., refractories, pencils).

Raymond Mill (Vertical Roller Mill): Very commonly used for grinding amorphous graphite to a fine powder. It is energy-efficient and provides good control over product fineness.

Summary Strategy for Amorphous Graphite:

Jaw Crusher → Hammer Crusher → Ball Mill / Raymond Mill. The process is straightforward, prioritizing throughput and operational cost.

Goal: Bust up those solid, chunky, usually pure graphite hunks. Flakes ain’t the worry here—it’s the rock-hard toughness and chopping size without dumping junk from worn-out gear.

Gear & Setup Picks:

Gotta hit a sweet spot: smash enough but keep the stuff clean.

Primary Crushing:

Jaw Crusher: Perfect first whack at the stubborn lumps.

Coarse & Fine Grinding:

Jaw Crusher + Cone Crusher Combo: When the ore’s extra tough, run a two-step crush before the grind—it saves hassle.

Rod Mill: Solid pick for the main grind. Handles the load smooth, spits out even chunks, way less muddy slop than a ball mill.

Ball Mill: Works if you need powder-fine. Pick linings and balls careful to dodge iron bits if staying pure matters big.

Fancy Upgrade:

Jet Mill: For top-shelf clean stuff—like grease or seals—this thing’s ace. Grinds with zero mess and nails the size spread.

Quick Plan for Vein Graphite:

Jaw Crusher → (Cone Crusher if needed) → Rod Mill or Ball Mill → Jet Mill (only for super-pure niche jobs). Pick based on how clean the end needs to be and how stubborn your vein graphite acts.

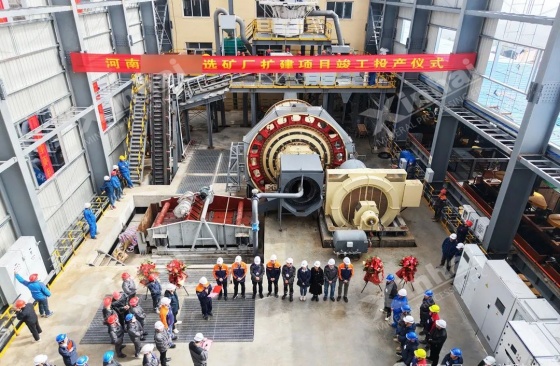

Xinhai Mining sells grinding equipment and also provides graphite ore beneficiation services. Please contact us if needed.