If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

In graphite mining, large flake graphite is highly valued due to its unique physical and chemical properties. However, its fragility makes it prone to damage during the mining process. Therefore, protecting large flake graphite and enhancing its recovery rate and quality are crucial challenges in graphite mining processes. This article introduces several effective methods for protecting large flake graphite in graphite mining.

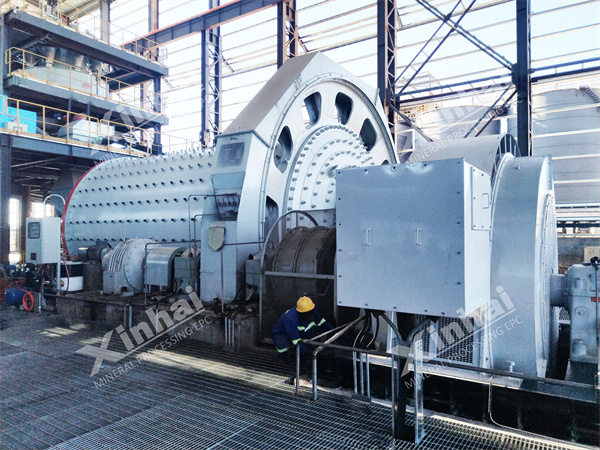

Graphite mining typically employs a multi-stage grinding process, with each stage involving low-intensity grinding. The purpose is to promptly separate liberated graphite flakes and avoid damage from grinding media and gangue minerals. Multi-stage grinding effectively reduces flake damage during grinding, increasing the recovery rate of large flake graphite.

In terms of grinding media, using steel rods instead of steel balls reduces impact and achieves a grinding effect, better protecting graphite flakes. Steel rods produce smaller impact forces during grinding, causing less damage to graphite flakes. This choice of grinding media can improve the recovery rate and quality of large flake graphite.

Modifying the structure of stirred mills to use scrubbers more suitable for graphite scrubbing instead of traditional stirred mills reduces damage to graphite flakes. These improved stirred mills can effectively scrub and liberate graphite while minimizing damage to flakes. Optimizing the structure of stirred mills enhances the efficiency and quality of graphite mining.

The starvation flotation method involves minimal or no reagent addition at the initial stages, utilizing the natural floatability of graphite to select large flake graphite early. This method avoids reagent adsorption and damage to graphite flakes, increasing the recovery rate of large flake graphite. Starvation flotation has significant application value in graphite mining.

Using flotation machines designed for coarse large flake graphite helps protect the structure of these flakes. The design and operational parameters of these machines better accommodate the flotation needs of large flake graphite, reducing damage to the flakes. Choosing the right flotation machine can improve the recovery rate and quality of large flake graphite.

For graphite ores with complex mineral compositions, intermediate products can be processed separately or jointly to address issues like low grade, fine dissemination, and complexity. Proper handling of intermediate products can enhance overall efficiency and quality while protecting large flake graphite.

Pre-screening or pre-separation processes can recover large flake graphite early, reducing damage during subsequent grinding and flotation processes. By separating large flake graphite early, it can be protected from damage in later stages. This method effectively increases the recovery rate of large flake graphite.

The classified grinding and flotation process involves re-grinding for 4 minutes, then screening into coarse and fine fractions. The coarse fraction undergoes gangue separation and further grinding and cleaning, primarily focusing on protecting large graphite flakes. The fine fraction undergoes staged grinding and flotation, considering monomer liberation, surface cleaning, and gangue mineral release to enhance fixed carbon content. This process effectively protects large flake graphite, improving mining efficiency and quality.

The rapid flotation process uses different flotation rates to quickly float graphite particles with high floatability, accelerating the process while minimizing damage to large flake graphite. This method effectively increases the recovery rate of large flake graphite and reduces its damage during flotation.

Ultrasonic assisted flotation enhances flotation efficiency, particularly in low-grade large flake graphite grinding and flotation processes. Ultrasonic waves emulsify flotation reagents, disperse solid particles in suspensions, and play a conditioning and flotation role during the process. This method effectively increases the recovery rate and quality of large flake graphite.

By employing these methods and technologies, large flake graphite can be maximally protected during graphite mining, enhancing product quality and recovery rates. These methods and technologies have significant application value in graphite mining processes, providing effective technical support and solutions for graphite mining enterprises.