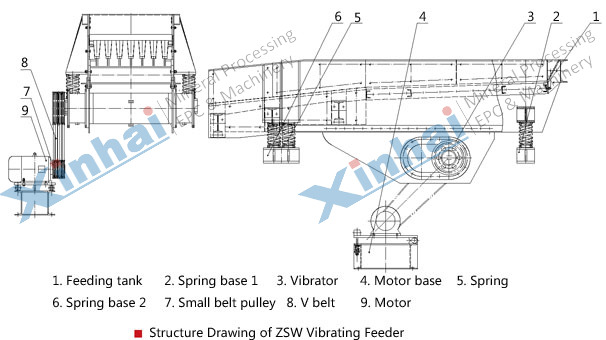

A mechanical vibrating ore feeding equipment with coarse screening function. 【Processing capacity】: 96~560t/h 【Scope of application】: It is mainly used for continuous and uniform feeding of conveyors, bucket elevators, crushers, ball mills and other equipment, and is used in automatic control systems to automate the production process.

The vibrating feeder has the advantages of simple structure, convenient installation, stable vibration, reliable operation, long service life, easy maintenance and repair, and easy realization of automatic control;

Adopting a double-shaft vibrator, linear vibration, the screening process is completed at the same time of feeding, which improves the utilization rate of the equipment and reduces the cost;

It can continuously and evenly feed the primary crusher, and at the same time conduct coarse screening of the material;

The frequency conversion motor can be optionally installed to adjust the frequency, thereby changing the output, which is convenient to control the feeding amount, and there is no need to start the motor frequently.

The vibration exciter is composed of two eccentric shafts with particular position. The large linear vibration force produced by motor and the rotation of two eccentric shafts vibrates the machine. The materials are sliding and thrown so that they could move on. When the materials pass the screen bars, the small ore falls through the clearance of screen bars.

| Model | Tank Dimensions (mm) | Max. Feed Size (mm) | Feed Capacity (t/h) | Rotating Speed of Eccentric Shaft (r/min) | Motor Power (kW) | Weight (kg) |

| ZSW380X95 | 3800X950 | 500 | 96~160 | 800 | 11 | 4082 |

| ZSW420X110 | 4200X1100 | 500 | 110~180 | 800 | 15 | 4149 |

| ZSW490X110 | 4900X1100 | 500 | 115~192 | 800 | 15 | 4263 |

| ZSW590X110 | 5900X1100 | 630 | 350~500 | 800 | 22 | 6130 |

| ZSW600X130 | 6000X1300 | 750 | 400~560 | 800 | 7800 |

A chemical plant in Guizhou intends to purchase 2 vibrating feeders from Xinhai. Xinhai takes into account the particularity of the industry's equipment requirements, and has relatively high pH requirements for materials, so the improved ZSW vibrating feeder is made of alloy steel plates to make feed troughs , used to ensure that high temperature wear and corrosive materials will not be affected in the conveying process. This type of feeder has a strong working capacity, can work for 10 hours a day, and transport about 10,000t of ore materials. It has high efficiency and is favored by customers.