A feeder with simple structure and suitable for non-cohesive materials. 【Processing capacity】: 7~1700t/h 【Scope of application】: It can be widely used in mining, metallurgy, building materials, light industry, chemical industry, electric power, machinery, food and other industries, and is used to uniformly and continuously or quantitatively supply block granular and powdery materials from silos or hoppers to receiving materials. It can be used in automatic batching, quantitative packaging, etc., and can be used in automatic control processes to realize the automation of production processes.

This type of vibrating feeder has simple structure, uniform feeding, good continuous performance and adjustable excitation force;

Change and control the flow at any time, easy to operate;

The eccentric block is the excitation source, with low noise, low power consumption, good adjustment performance, and no punching phenomenon;

If the closed body is used, dust pollution can be prevented and the vibration is stable;

Reliable work and long life;

The flow can be changed and controlled at any time, and the adjustment is convenient and stable;

Simple structure, reliable operation, convenient adjustment and installation, light weight, small size, convenient maintenance;

Dust contamination can be prevented when using a closed structure body.

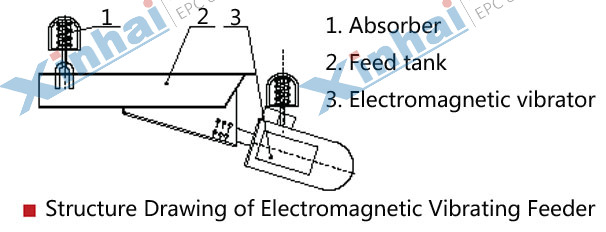

The electromagnetic vibrating feeder utilizes an electromagnetic vibrating device to drive minerals to reciprocate in the direction of dip. When the vertical component of accelerated speed of feeder exceeds accelerated speed, minerals are tossed upward and leap forward in a parabolic fashion. It takes 1/5 second to finish the rising and falling. The chute vibrates for one time and subsequently, the minerals are tossed for one time. The chute vibrates at a frequency of 3000/minute. Correspondingly, minerals are tossed upward and has a leap forward. So minerals can continuously and uniformly move forward and feeding is achieved.

| Model | Tank Dimension (LXWXH) (mm) | Feed Size (mm) | Horizontal Feed Amount (t/h) | Feed Amount (t/h) | Power (kW) | Overall Dimension (LXWXH) (mm) | Weight (kg) |

| GZ1 | 600X200X100 | 50 | 5 | 7 | 0.06 | 910X376X485 | 80 |

| GZ2 | 800X300X120 | 10 | 14 | 0.15 | 1175X608X600 | 165.5 | |

| GZ3 | 900X400X150 | 75 | 25 | 35 | 0.2 | 1325X578X675 | 223 |

| GZ4 | 1100X500X200 | 100 | 50 | 70 | 0.45 | 1616X762X814 | 462 |

| GZ5 | 1200X700X250 | 150 | 100 | 140 | 0.65 | 1815X840X980 | 656 |

| GZ6 | 1600X900X250 | 200 | 150 | 210 | 1.5 | 2410X10925X1500 | 1252 |

| GZ7 | 1800X1100X250 | 250 | 250 | 350 | 3 | 2800X1330X1710 | 2017 |

| GZ8 | 2200X1300X300 | 300 | 400 | 560 | 4 | 3302X1556X1995 | 3153 |

| GZ9 | 2400X1500X300 | 350 | 600 | 840 | 5.5 | 3515X1776X2200 | 3750 |

| GZ10 | 2500X1800X375 | 500 | 750 | 1050 | 4X2 | 3630X2500X2235 | 6491 |

| GZ11 | 2800X2000X375 | 1000 | 1400 | 5.5X2 | 4060X2640X2919 | 7680 | |

| GZ12 | 3000X2200X400 | 1200 | 1500 | 15 | 5260X2860X2563 | 8840 | |

| GZ13 | 3200X2500X450 | 1300 | 1600 | 6394X3040X2864 | 9920 | ||

| GZ14 | 3500X2500X450 | 550 | 1500 | 1700 | 18.5 | 7475X3802X3000 | 11000 |

A copper ore dressing plant in Henan came to Xinhai to inquire about a feeder that saves land and is easy to maintain. Xinhai recommends an electromagnetic vibrating feeder integrating electromechanical and mechanical according to customer requirements. Compared with other series of feeders, the electromagnetic vibrating feeder is simpler in structure, occupies a small area, and is convenient for installation and post-maintenance. In the process of use, the feeding amount can be easily adjusted, the centralized control and automatic control of the production process can be realized, and the expected effect of the factory has been achieved.