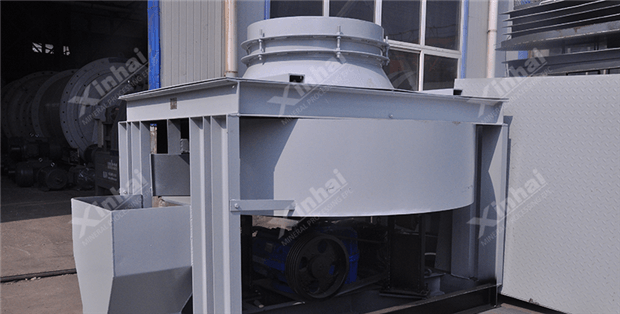

A traditional continuous feeding equipment for powdery materials. 【Processing capacity】: 0~88.4t/h 【Scope of application】: The disc feeder is suitable for feeding various non-viscous materials, but not suitable for powdery materials with good fluidity. It is suitable for suspending on steel structures in concentrators, smelters, cement plants, sand mines, mechanized foundries and other departments, and installing it under the hopper for continuous feeding.

The disc feeder is stable and easy to operate;

Wide range of applications, energy saving and high efficiency;

Large bearing capacity and stable operation;

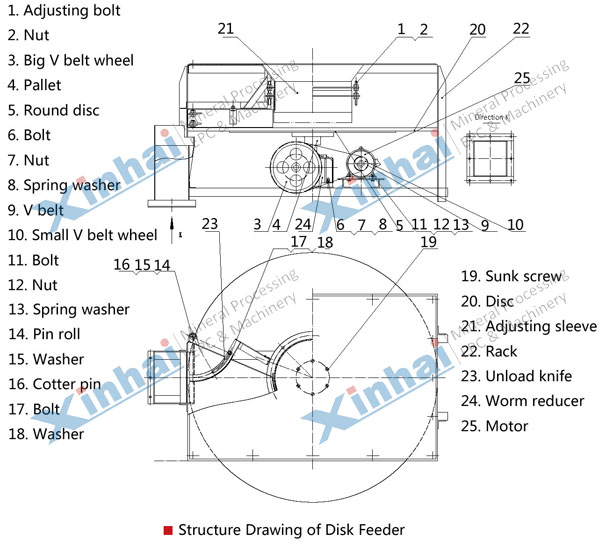

It has the advantages of simple structure, uniform feeding and reliable use. If the distance between the adjusting sleeve and the disc is changed, the purpose of adjusting the feeding amount can be achieved.

Bulk materials are loaded into the receiving cylinder from the hopper. The materials are not exposed to the wall of the cylinder and piled on the disc by their own weight. Adjust the gap between the sleeve and the disc by adjusting the bolt to control the natural pile of materials on the disc. angle. When the disc rotates, the material is evenly scraped by the discharge knife on the disc to the outside of the disc and falls, so that as the disc rotates, the material is evenly scraped into the receiving hopper by the discharge knife. Continuous operation of the disc completes the uniform feeding operation. Adjusting the gap between the unloading knife and the disc can also control the amount of feed. When working, the motor drives the disk mounted on the worm reducer to rotate through the pulley.

| Type | Model | Disk Diameter (mm) | Rotating Speed of Disk (r/min) | Max. Feed Size (mm) | Feed Capacity (t/h) | Motor Model | Motor Power (kW) | Weight (kg) |

| YG300 | 300 | 10. 0 | 20 | 0~ 1. 8 | Y80L- 4 | 0. 55 | 115 | |

| YG400 | 400 | 10. 7 | 0~ 2. 6 | Y90L- 6 | 1. 1 | 120 | ||

| YG500 | 500 | 0~ 3. 3 | 124 | |||||

| Close | YG600 | 600 | 10. 0 | 0~5. 0 | 130 | |||

| Hanged | YG800 | 800 | 9 | 30 | 0~8. 0 | Y80L- 4 | 0.55 | 195 |

| YG1000 | 1000 | 9 | 30 | 0~ 12 | Y90L- 4 | 1. 5 | 263 | |

| YG1500 | 1500 | 7 | 40 | 0~ 22 | Y132M2-6 | 5. 5 | 755 | |

| YG2000 | 2000 | 5 | 50 | 0〜80 | Y160L-6 | 11 | 2517 | |

| DK600 | 600 | 7. 53 | 25 | 1. 8~ 3. 9 | Y90L- 6 | 1. 1 | 410 | |

| DK800 | 800 | 7. 53 | 30 | 3. 5~ 7. 6 | 600 | |||

| DK1000 | 1000 | 7. 50 | 40 | 1.8〜16.7 | Y100L- 6 | 1. 5 | 725 | |

| Open Hanged | DK1300 | 1300 | 6. 5 | 50 | 4. 3~27. 9 | Y132S- 6 | 3 | 846 |

| DK1600 | 1600 | 6 | 60 | 7.03~48.6 | Y132M1- 6 | 4 | 1980 | |

| DK1800 | 1800 | 5 | 70 | 9.26~60 | Y132M2- 6 | 5.5 | 3070 | |

| DK2000 | 2000 | 80 | 13.6~88.4 | Y132M2- 6 | 3260 |

An iron concentrator in Shandong purchased a disc feeder in Xinhai, which uses a fused ceramic lining plate, which has strong anti-scour and grinding capabilities. In practical applications, no production accidents such as material leakage or equipment damage have occurred, and it is safer than ordinary equipment. Improve, to ensure the smooth progress of the plant's production. The disc feeder makes the material evenly enter one equipment so that the next process can work normally, saves labor, protects the performance of the equipment, and prolongs the service life of the entire production line equipment.