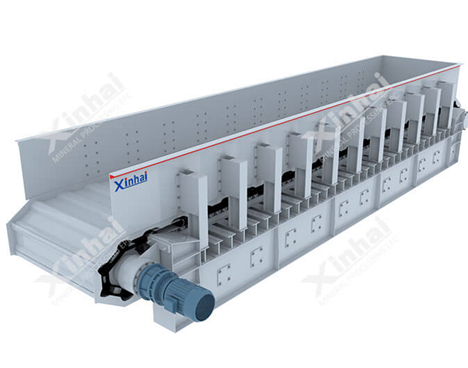

A feeder device for short distance conveying. 【Processing capacity】: 15~400m3/h 【Scope of application】: Widely used in crushing and grading workshops and cement in large concentrators. In building materials and other departments, it is used for continuous and uniform feeding of the silo to the primary crusher, and it can also be used for short-distance transportation of materials with large particle size and specific gravity. , and its upward inclination angle is 20°.

It can be installed horizontally or obliquely, and the inclination angle is less than or equal to 12°;

In order to prevent the material from hitting the feeder directly, it is required that the silo does not appear empty;

The upper limit of feeding particle size can reach 1000mm.

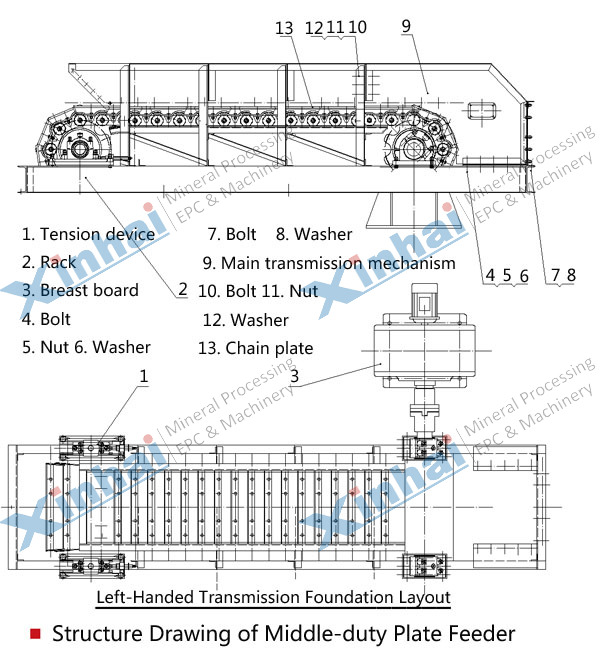

The main work of the feeder is to make the motor power through reducer, arrive the connecting rod of the eccentric gear do the reciprocating motion, and also make the pawl push the ratchet to drive the rotation of the chain wheel. Thereby the intermittent motion of the chain plate will begin so as to achieve the purpose of conveying materials.

Heavy-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 1000 mm or less.

Medium-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 400 mm or less. It usually applies to transport the materials with the loose density of less than 2400 kg/m3, the block weight of less than 500 kg, and the temperature of below 400 ℃.

Light-duty plate feeder: It is suitable for short-distance transportation of the block materials with feed size of 160 mm or less. It usually applies to transport the materials with the loose density of less than 1200 kg/m3, the block weight of less than 140 kg, and the temperature of below 350 ℃.

| Model | Chain Plate | Feed Size (mm) | Capacity (m3/h) | Motor | Overall Dimension (LXWXH) (mm) | Weight (kg) | |||

| Width (mm) | Center Distance of Chain Wheel (mm) | Speed (m/s) | Model | Power (kW) | |||||

| GBH80-2.2 | 800 | 2200 | 0.01 ~0.053 | ≤300 | 15 ~91 | Y132M-4 | 7.5 | 3840X2850X1185 | 3722 |

| GBH80-3 | 3000 | XWED106-385-4 | 4 | 4868X2705X1060 | 4014 | ||||

| GBH80-4 | 4000 | Y132M-4 | 5640X2986X1185 | 5087 | |||||

| GBH80-5.8 | 5800 | 0.18 | ≤300 | 15 ~91 | XWED7.5-8215A-231 | 7.5 | 7760x2823.5x1321 | 6526.7 | |

| GBH100-1.6 | 1000 | 1600 | ≤0.15 | ≤350 | 22~131 | Y160M-6 | 3240X3026X1235 | 3981 | |

| GBH100-3 | 3000 | 4640X3114X1235 | 4548 | ||||||

| GBH100-4 | 4000 | 0.01 ~0.053 | 22~131 | XWED106-385-4 | 4 | 5648x2890x1160 | 5086 | ||

| GBH120-1.8 | 1200 | 1800 | ≤0.15 | 300-400 | 35~217 | Y160M-6 | 7.5 | 3440X3314X1235 | 3965 |

| GBH120-2.2 | 2200 | 3840X3314X1285 | 4238 | ||||||

| GBH120-2.6 | 2600 | 4240X3314X1285 | 4572 | ||||||

| GBH120-3 | 3000 | XWED7.5-8215A-273 | 4960X3150X1434 | 4886(Exclude Reducer) | |||||

| GBH120-4 | 4000 | Y160M-6 | 5640X3402.5X1285 | 6100 | |||||

| GBH120-4.5 | 4500 | XWED7.5-8215A-273 | 6460X3150X1434 | 6350.6 (Exclude Reducer) | |||||

| GBH120-6 | 6000 | 300-400 | 35~217 | XWED11-8225B-273 | 11 | 7960x3242x1434 | 8210 | ||

Changsha No. 1 Copper Mine Concentrator and Xinhai Mining have signed an overall service project for the concentrator. Among them, the apron feeder equipment is selected as two GBZ180-12 heavy-duty apron feeders, which are used as the feeding equipment of the crusher. The average is 240m3/h, and the feeding particle size is about 800mm. This kind of plate feeder has large processing capacity, high efficiency and stable ore feeding. This plant is also an old customer who chose Xinhai for the second time.