A self-aspirated mechanically agitated rod flotation machine. 【Processing capacity】: 1.5~4 m³/min 【Scope of application】: XJB rod flotation machine is suitable for processing metal ores with high density and coarse particle size in medium and small concentrators. It can be used in various flotation operations, especially suitable for processing lead, zinc, copper, molybdenum, sulfur and silica sand. Sorting.

The flotation machine is particularly suitable for the flotation of mineral materials with large specific gravity, fast settling speed and coarse materials;

It has a special steady flow plate, which is composed of many arc blades with different lengths welded on the bottom lining plate of the tank, which can make the slurry gas mixture evenly distributed in the tank and prevent the slurry from rotating in the tank;

Large air volume, strong stirring force and high bubble dispersion;

Slurry, gas and medicine are mixed evenly;

Fast flotation;

Flotation machine models are complete.

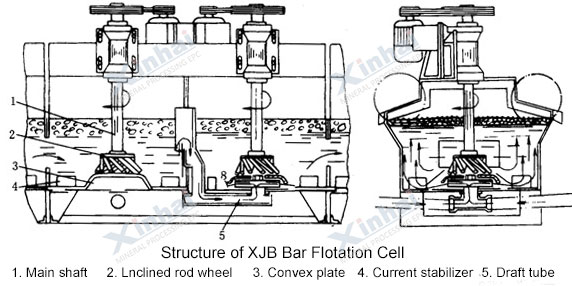

The bar flotation cell has air inflation agitation group consisting of oblique rod wheel, convex plate, arc stabilizer, etc. The impeller is consisted of a disc and 12 bevel cone bars. The rotating speed of bevel cone bar gets faster and faster while downing and agitation force gets stronger accordingly.

The negative pressure generated by the revolving impeller or rod wheel is used to suck the air from the hollow shaft, and then the flotation wheel divides it to form tiny bubbles, and then the impeller or rod wheel strongly stirs and throws it, so that the slurry and air are fully mixed, and under the action of the slanting rod of the flotation wheel, the useful mineral particles, which are treated with flotation reagents (collectors), are selectively attached to the bubbles and float to the pulp surface, and then scraped into the concentrate tank by the scraper, thus completing the separation.

| Model | Tank Type | Effective Volume(m3) | Capacity(m3/min) | Impeller Diameter(mm) | Impeller Rotation Speed(r.p.m) | Motor Power for Agitation(kw) | Motor Power for Scraper(kw) | 4 Tank Weight(kg) |

| XJB-1 | Suction Tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5344 |

| XJB-1 | Direct Flow Cell | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5344 |

| XJB-1D | Suction Tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5479 |

| XJB-1D | Direct Flow Cell | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5479 |

| XJB-2 | Suction Tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9071 |

| XJB-2 | Direct Flow Cell | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9071 |

| XJB-2D | Suction Tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9320 |

| XJB-2D | Direct Flow Cell | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9320 |

| XJB-4 | Suction Tank | 4 | 2.0-4 | 700 | 280 | 18.5 | 1.1 | 16325 |

| XJB-4 | Direct Flow Cell | 4 | 2.0-4 | 510 | 280 | 18.5 | 1.1 | 16325 |

An Anhui copper mine processing plant has chosen Xinhai as a general contracting service for beneficiation. In the flotation process, due to the large proportion and coarse particle size of the ore processed by the plant, Xinhai Mining designed and transformed XJB rod flotation for it. It uses high manganese steel to cast steel bars, and the wear resistance is greatly improved, breaking the previous situation of low durability of bar flotation machines. In the flotation process, the treatment capacity reaches 3000t/d, and the energy consumption cost is relatively low.