A non-suction, self-aspirating mechanically agitated flotation machine (refer to the design of the American Wemco flotation machine). 【Processing capacity】: 2-20m3/min 【Scope of application】: JJF flotation machine can be widely used in the separation of non-ferrous metals, ferrous metals, and non-metallic minerals, and is suitable for roughing and sweeping operations in large and medium-sized flotation plants.

Xinhai jjf flotation machine is of shallow groove type, with small impeller diameter, low speed and low power consumption;

The gap between the impeller and the stator is large, and the stator is a cylinder with an elliptical hole, which is conducive to the mixing and dispersion of air and pulp;

The height of the stator is lower than that of the impeller, and the amount of pulp circulation is large, up to 2.5 times;

The umbrella-shaped dispersing cover with holes of the stator can separate the eddy current generated by the impeller from the foam layer, so that the pulp surface can be kept stable;

The amount of pulp circulation is large, up to 2.5 times, which is beneficial to the mineralization of ore, medicine and gas;

Large inhalation volume and good dispersion effect;

The stirring degree is moderate, the solid particles are well suspended, no sinking, and no ore drawing is required for parking;

The size range that can be processed is wide, and the beneficiation recovery rate is high;

Mechanical stirring, self-aspirating, not self-absorbing pulp, the operation room needs to be equipped with steps (the drop is 300-400mm);

It can be combined with SF type flotation machine to form a combined flotation unit. SF type flotation machine is used as suction tank, and JJF type is used as direct flow tank.

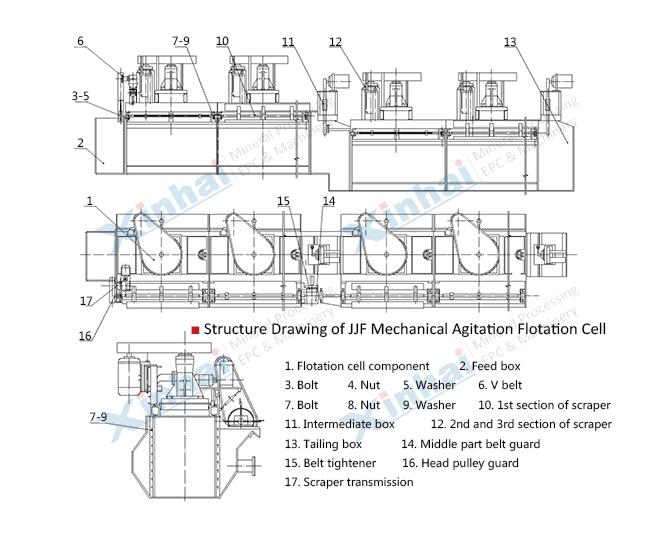

When the JJF mechanical agitation flotation machine is working, vortexes are generated in the vertical tube and the draft tube. This vortex forms a negative pressure and sucks the air from the air inlet pipe. It is mixed with the pulp sucked by the diversion pipe in the impeller and stator regions.The slurry-gas mixed flow is moved in a tangential direction by the impeller, and then converted into radial movement by the action of the stator, and is evenly distributed in the flotation cell. The mineralized bubbles rise to the froth layer and are scraped out unilaterally or bilaterally to form froth products.

| Model | Effective Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Revolution (r/min) | Motor Power for Agitation (kW) | Motor Power for Scraper (kW) | Single Tank Weight (kg) |

| JJF-4 | 4 | 2.0~4 | 410 | 305 | 11 | 1.5 | 2303 |

| JJF-5 | 5 | 2.0~6 | 410 | 305 | 11 | 1.5 | 2416 |

| JJF-8 | 8 | 4.0~12 | 540 | 233 | 22 | 2.2 | 4507 |

| JJF-10 | 10 | 5.0~10 | 540 | 233 | 22 | 1.5 | 4820 |

| JJF-16 | 16 | 5.0~16 | 700 | 180 | 37 | 1.5 | 7657 |

| JJF-20 | 20 | 5.0~20 | 770 | 180 | 45 | 1.5 | 8505 |

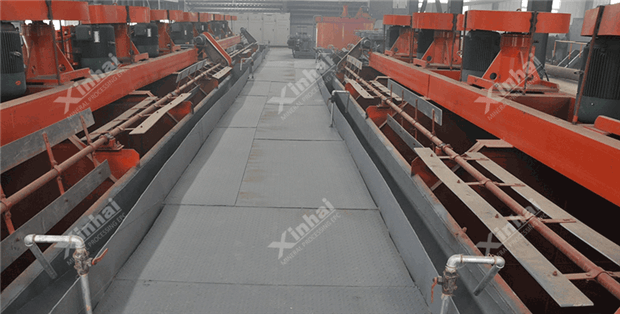

Xinhai is a copper mine beneficiation test, the selected flotation equipment is jjf flotation machine, and 24 jjf-16 flotation machines are selected in the design, of which 6 are a series. In order to test the processing capacity of the flotation machine, two kinds of tests of the flotation machine in series and in parallel were carried out respectively. Finally, after two sets of multiple tests, Xinhai chose the flotation machine series method for the copper ore processing plant: open two pairs of ball mills , the amount of ore processed is 110t/h, and the amount of pulp is 285.52m3/h. At this time, the liquid level and foam volume in the jjf flotation machine tank are moderate, and the flotation scraping foam is normal.