A self-priming, self-aspirating mine sf flotation machine equipment. 【Processing capacity】: 0.24~12m3/min 【Scope of application】: The sf flotation machine can be widely used in the sorting of non-ferrous metals, ferrous metals and non-metallic minerals, and is suitable for roughing and sweeping operations in large and medium-sized flotation plants.

The impeller has backward inclined double-sided blades, which can realize double circulation of pulp in the tank;

The gap between the impeller and the cover plate is large, and the suction volume is large;

Low peripheral speed of impeller, long life of wearing parts;

Forward inclined tank body, small dead angle, fast foam movement;

Large air intake and low energy consumption;

Long life of wearing parts;

It is beneficial to the flotation of coarse-grained minerals;

Mechanical stirring, self-suction, self-suction pulp;

It can be combined with JJF flotation machine to form a combined flotation unit as the suction tank for each operation.

The working principle of the SF flotation cell: When the impeller rotates, the pulp in the upper and lower impeller cavities generates the centrifugal force under the action of the upper and lower blades and is thrown to the four sides, forming a negative pressure zone in the upper and lower impeller cavities. At the same time, the pulp on the upper part of the cover plate is inhaled into the upper impeller cavity through the circulation hole on the cover plate, forming an upcycling of the pulp. When the lower blade throws the pulp around, the lower pulp adds to the center, thus forming the lower cycle of the pulp. The air is sucked into the upper impeller chamber through the suction tube and the central tube, and mixed with the pulp to form many fine bubbles. After the steady flow through the cover plate, the air is evenly dispersed in the tank to form mineralized bubbles. The mineralized bubbles rise to the foam layer and are scraped out by the scraper.

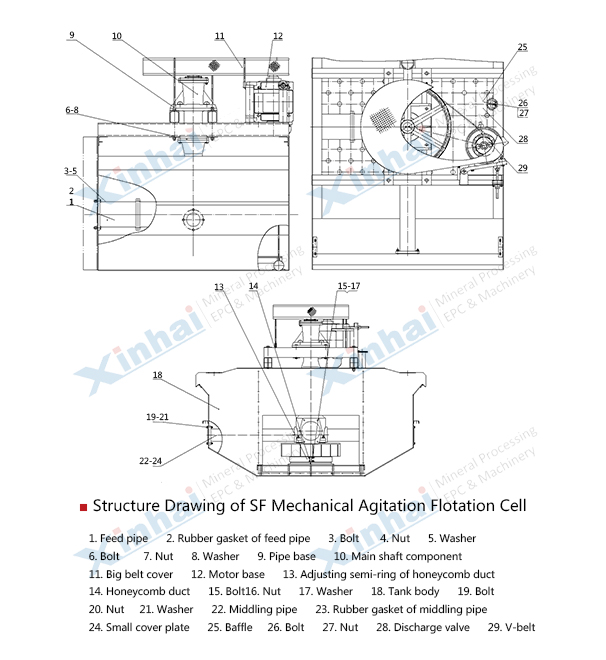

The structure of the SF flotation cell is mainly composed of the tank, impeller, motor, scraper and transmission device, etc. The volume of the SF flotation cell is more than 10m³.

| Model | Effective Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Revolution (r/min) | Motor Power for Stir (kW) | Motor Power for Scraper (kW) | Single Tank Weight (kg) |

| SF-0.37 | 0.37 | 0.2~0.4 | 300 | 352~442 | 1.5 | 0.55 | 468 |

| SF-0.7 | 0.7 | 0.3~1.0 | 350 | 336~384 | 3 | 1.1 | 629 |

| SF-1.2 | 1.2 | 0.6~1.6 | 450 | 312 | 5.5 | 1.1 | 1373 |

| SF-2 | 2 | 1.5 ~3 | 550 | 280 | 11 | 1.5 | 1879 |

| SF-2.8 | 2.8 | 1.5~3.5 | 550 | 280 | 11 | 1.5 | 1902 |

| SF-4 | 4 | 2.0 ~4 | 650 | 235 | 15 | 1.5 | 2582 |

| SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 | 3540 |

| SF-8 | 8 | 4.0 ~8 | 760 | 191 | 30 | 2.2 | 4129 |

| SF-16 | 16 | 5.0 ~16 | 850 | 169~193 | 45 | 1.5 | 7415 |

| SF-20 | 20 | 10 ~12 | 850 | 169~193 | 45 | 1.5 | 9828 |

A copper beneficiation plant in Yunnan only used gravity separation in the beneficiation process, and the concentrate grade after beneficiation was low. Introduced by a friend to Xinhai Mining for consultation, and finally through the beneficiation test, it is determined that the process is the heavy-flotation process. In the flotation process, the SF-type mechanical stirring flotation machine independently developed by Xinhai is used. The design of the forward-inclined tank body reduces the dead angle in the operation process, accelerates the movement of the foam and improves the separation efficiency. After sorting, the concentrate grade was 10% higher than expected, and the follow-up economic benefits of the plant were guaranteed.