A uniquely designed dewatering equipment with large capacity and sufficient dewatering. 【Processing capacity】: ≤250t/h 【Scope of application】: Xinhai high-efficiency high-frequency dewatering screen is widely used in filtration and dewatering equipment industries such as tailings dry discharge, concentrate dewatering, refining mud concentration, debris removal, and carbon slurry separation. Xinhai high-efficiency dewatering screen is especially suitable for processing fine-grained minerals. It can also be used in conjunction with Xinhai XC series cyclone, which has higher and more sufficient dewatering efficiency. It can be widely used in tailings dry discharge, concentrate dewatering and other operations.

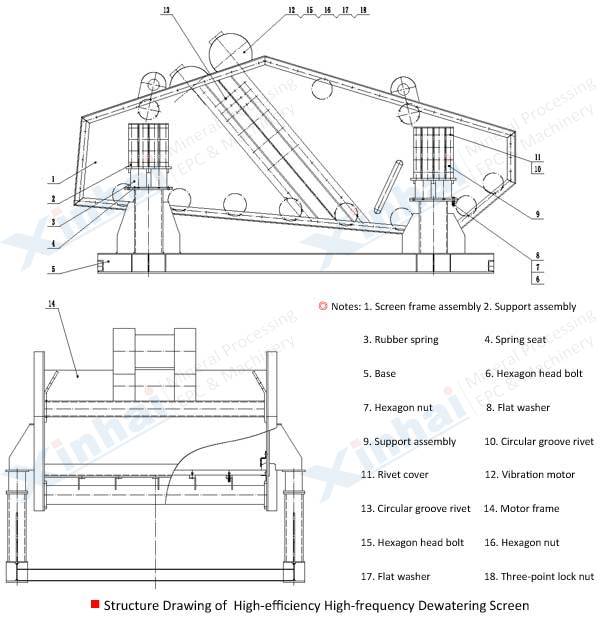

Xinhai high-frequency dewatering screen is integrally riveted to the screen box, with high strength, good rigidity, no thermal stress, modular screen plate and sealing strip installation form, and good sealing effect;

The side guards of Xinhai tailings dewatering screen are adhered with wear-resistant rubber to ensure that the dewatering screen will not be deformed and ruptured due to wear and tear, and reduce the pollution of iron to materials;

The contact material position is covered with wear-resistant natural rubber, which is anti-corrosion and wear-resistant;

Rear low-concentration slurry overflow pipe to speed up dehydration;

-5° inclination angle screen surface makes the water content of the material on the screen lower;

Wear-resistant rubber damping device makes the screen run more smoothly and lastingly;

The high-efficiency dewatering screen has a complete range of models and high dewatering efficiency.

The product adopts a double vibration motor as a power supply: The two motors that rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of a straight line, which is for dehydration. The screen frame is connected by high-intensity bolts, so the structure is stable and durable.

| Model | Min. 30% Solid Feeding Slurry Concentration by Volume | Unit Motor Power (kW) X Quantity (set) | ||||||

| Coal Fine Theoretically -0.5+0.1(mm) Specific Gravity 1.5 | Coarse Sand Approxilly- 5(mm) 100%, -0.6(mm)50%, Specific Gravity 2.7 | Fine Sand 90% -1(mm) Specific Gravity 2.7 | 980 (r/min) | 1460 (r/min) | ||||

| 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | |||

| VD6 | 6~8 | 10 ~13 | 14 | 28 | 10 | 21 | 2 X2 | |

| VD9 | 9~12 | 15 ~20 | 21 | 42 | 16 | 32 | 3X2 | |

| VD12 | 15 ~19 | 24 ~30 | 33 | 67 | 25 | 50 | 2.6X2 | 4X2 |

| VD15 | 30 ~35 | 50 ~60 | 63 | 125 | 47 | 94 | 2.4X4 | 2.25X4 |

| VD18 | 35~45 | 60 ~80 | 77 | 153 | 57 | 115 | 3.7X4 | |

| VD21 | — | 85~100 | — | 225 | — | 164 | 15 | — |

| VD24 | 95~110 | 250 | 190 | |||||

A gold beneficiation plant in Northeast China has a large ore processing capacity. In order to save money and want to use one machine for multiple purposes, Xinhai high-efficiency high-frequency dewatering screen is selected. According to the customer's supplementary requirements, the technicians improved the dewatering screen by applying dual-motor synchronous technology, universal eccentric block and adjustable amplitude vibrator, which reduced the damage to the motor and saved money. Compared with the previous dewatering screen, the life of the machine is nearly doubled during the actual use of the machine. The customer is very satisfied and has reached a long-term cooperative relationship with us.