If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Tailings storage facility(TSF) engineering services refer to complete solutions covering preliminary design, construction contracting, intelligent monitoring, and operational maintenance management. Today, TSF projects commonly face three major problems: unreasonable design, non-standard construction, and failure to pass acceptance inspections, which severely restrict project operation. Addressing these pain points, Xinhai provides full-process TSF engineering services covering design-construction-supervision, systematically resolving customer challenges and ensuring project safety, standardization, and sustainability.

Site Investigation and Selection: Organizes geological and hydrogeological surveys, provides feasibility assessments and dam type recommendations.

Engineering Design: In-house design team produces design drawings + construction drawings according to the latest standards, meeting environmental impact assessment (EIA) and safety assessment requirements.

Construction Management: In-house civil and hydraulic engineering teams, with phased construction and dynamic monitoring carried out simultaneously.

Environmental Compliance and Permitting: Familiar with local policy processes, provides early involvement in EIA and documentation preparation and technical coordination and technical coordination.

Operational Support: Provides storage capacity monitoring, embankment maintenance, and drainage system operational guidance to ensure long-term safe operation.

Xinhai can provide various TSF design services, covering the following main types to fully meet different project requirements and geological conditions:

Upstream Method TSF

The embankment is formed by successively raising the crest upstream from the initial starter dam, building upon previously deposited tailings. The overall structure consists of the initial dam and the cycloned or spigotted tailings beach. The stability of the raised embankment relies primarily on the shear strength of the compacted tailings themselves. This method is relatively simple and widely applicable.

Centerline Method TSF

Tailings are deposited to raise the crest vertically above the centerline of the initial starter dam, expanding equally towards both the upstream and downstream directions. This method results in a symmetrical dam structure with high stability, offering excellent seismic resistance and seepage control performance. However, it requires higher standards for foundation treatment and material control, making it suitable for projects with favorable geological conditions.

Downstream Method TSF

The raised embankment is constructed downstream of the initial starter dam, systematically building the crest higher and the slope further outwards. This dam type offers high stability and a strong safety factor, making it particularly suitable for high seismic zones and scenarios with strict environmental requirements. However, it generally requires larger quantities of fill material, necessitating a comprehensive evaluation of economics and safety.

Once-through Construction (Embankment) Dam TSF

Refers to constructing the entire dam to its final design height during the initial construction phase, with no large-scale raising required later. This type offers excellent structural integrity, simplified operation and maintenance, and high long-term safety. It is suitable for projects with defined storage capacity needs and limited site space. Although the initial investment is relatively high, it can significantly reduce subsequent O&M costs and risks.

Site-Specific Adaptation: Xinhai's design team is familiar with the tailings characteristics of various ore types and domestic and international design codes, enabling them to propose practical, system solutions compliant with environmental regulations, tailored to the specific site conditions.

Ore-Specific Customization: Based on the properties of different ore tailings, topography, geology, hydrogeological environment, and other characteristics, Xinhai customizes the TSF location, dam structure, discharge method (slurry/thickened/paste/tailings filtering), and storage capacity staging strategy. This achieves the optimal balance between safety, economy, and adaptability.

Dam Construction: Execution of dam foundation preparation, layered filling, compaction, and anti-seepage treatment to ensure dam strength and stability.

Pipeline and Discharge System Construction: Installation of key systems including tailings delivery pipelines, spillways, and seepage collection/drainage networks, ensuring safe tailings discharge and water recycling.

Ancillary Facility Construction: Building of monitoring wells, collection ponds, return water pump stations, and other ancillary systems to enhance overall project operational efficiency and safety performance.

Safety Management: Implements quality testing, construction supervision, and on-site safety control throughout the entire process, strictly managing every work procedure.

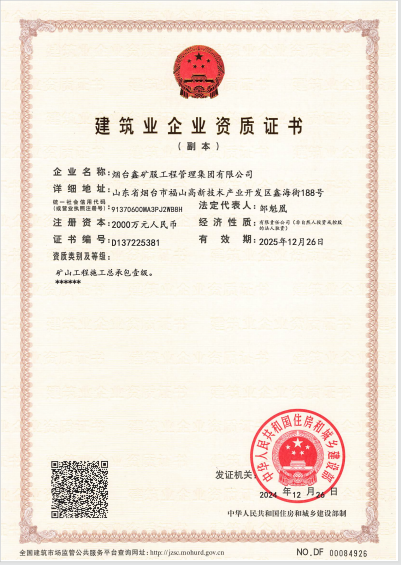

Grade I Mine Construction Qualification: Xinhai holds the national Grade I Qualification for General Contracting of Mine Engineering Construction, integrating industry resources and experience. This demonstrates the demonstrating strong technical and management capacity to undertake various large-scale, complex tailings storage facilities and their ancillary structures.

Rapid Construction: Xinhai provides full-process services for tailings storage facilities. Through lean operation and scientific management, Xinhai not only advances projects efficiently and shortens construction cycles but also ensures project quality under challenging geological and climatic conditions, achieving comprehensive cost optimization.

Safety and Environmental Protection: Strictly adheres to green mining and the "Three Simultaneities" policy (simultaneous design, construction, and operation of environmental protection facilities). Synchronously constructs anti-seepage, seepage control, reservoir drainage, tailings water recovery, and intelligent early warning systems, comprehensively ensuring ecological environmental protection and personnel safety during TSF operation.

Guaranteed Quality: Xinhai fully undertakes all construction works, including embankment foundation preparation, dam raising, and transport/discharge systems. The company is equipped with specialized machinery and an experienced technical team, supported by meticulous construction organization and strict on-site safety management, ensuring high-quality project delivery.

Operational Phase Technical Support: Provides embankment stability monitoring, operational data analysis, regular safety inspections, and technical assessments.

Staged Raising and Capacity Expansion Management: Develops rational raising construction and storage capacity expansion plans based on tailings deposition progress, extending the TSF's service life.

Intelligent Management System Deployment: Implements in-situ monitoring, remote data acquisition, and early warning systems, enabling digitalized operation management of the TSF.

Environmental Compliance and Regulatory Services: Assists clients in dealing with environmental reviews and safety assessments, ensuring the long-term operation of the TSF meets national and regional regulatory requirements.

Intelligent Monitoring: Xinhai deploys intelligent systems for embankment displacement, pore water pressure, water level, rainfall monitoring, and remote linkage alarms for clients. These are integrated to build a unified digital management platform for the TSF, enabling accurate risk prediction, real-time warning response, and multi-dimensional data visualization, fully empowering clients towards intelligent operations.

Long-Term Operational Maintenance: After the TSF is commissioned, Xinhai provides value-added services covering the entire lifecycle, including storage capacity management, embankment raising, routine maintenance, safety assessments, and environmental compliance rectifications, ensuring the long-term safety, stability, and compliant operation of the facility.

Tanzania 3000t/d Graphite Mine ML644 TSF Design

Malawi 440,000 t/a Monazite Rare Earth Mine TSF

Nicaragua 1000t/d Gold Cyanidation Plant and TSF Design