If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Improving recovery rate is a goal pursued by every mineral processing plant. Every step in the beneficiation production line influences the final recovery rate. Agitation is an essential step prior to flotation but is often overlooked and considered unimportant. In fact, the rational design of the agitation tank is crucial. Traditional agitation tanks have inherent design flaws. After years of R&D to break through these bottlenecks, Xinhai has produced a high-efficiency agitation tank that effectively avoids the defects of traditional agitation tanks. This article will compare the Xinhai High-Efficiency agitation tank with traditional aagitation tank.

The inherent design limitations of traditional agitation tanks constrain the improvement of overall process efficiency. The main design flaws are:

Dead zones exist within the tank body where fluid cannot effectively reach, causing some minerals and reagents to fail to participate in effective reactions, leading directly to the waste of both resources and reagents.

Traditional agitation tanks typically use small-diameter, twisted ribbon impellers with low linear speed, resulting in weak agitation force. This directly leads to insufficient negative pressure within the tank and poor pulp circulation capacity. It's like an underpowered stirring rod, unable to create uniform rolling of the contents in the tank. The result is that the mixing effect of minerals, reagents, and air remains superficial, failing to achieve deep mutual attachment.

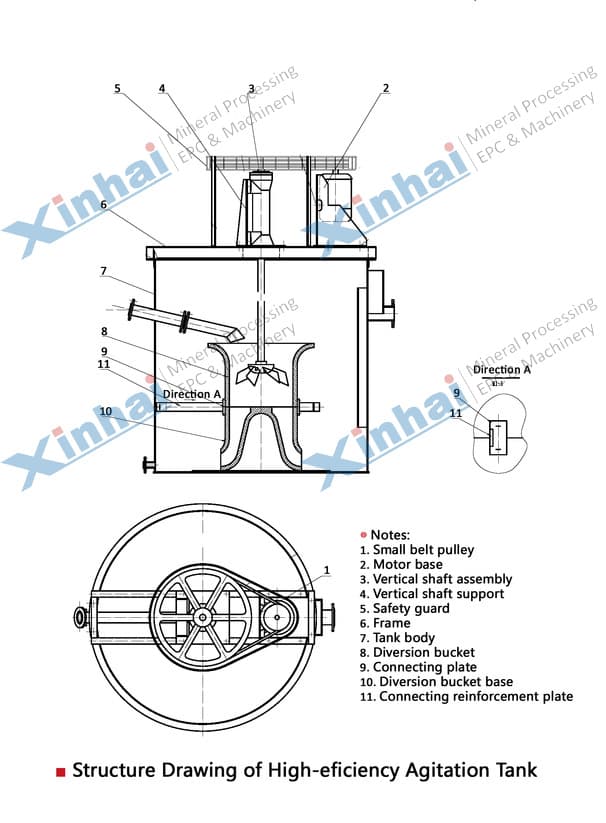

Addressing these industry pain points, the Xinhai High-Efficiency Agitation Tank represents a revolutionary step in design philosophy, providing powerful technological responses to each weakness of traditional agitation tanks.

Versus traditional small twisted ribbon impellers. Xinhai employs a large-diameter, high-linear-speed umbrella impeller, akin to equipping the mixer with a powerful "heart". The umbrella structure generates intense radial and axial flows, increasing agitation capability exponentially and creating a massive negative pressure zone, laying the foundation for highly efficient circulation.

To solve the problem of weak circulation inherent in traditional designs, Xinhai developed its own circulator, which is a core patented technology. A unique "circulator" added inside the tank concentrates and confines the large-scale negative pressure generated by the impeller within a "high-speed reaction chamber". Here, the pulp flow velocity increases sharply, and the circulation capacity is utilized to its maximum, ensuring violent collision and sufficient attachment of minerals, reagents, and air.

Completely eliminating the dead zones found in traditional agitation. Below the circulator, an innovatively added jet device acts like a booster, vigorously agitating the tank bottom and pushing the pulp upward, creating powerful convection. The entire fluid inside the tank exhibits a "turbo-charged" motion state, ensuring mixing without blind spots and more thorough mineralization.

Guaranteed by these three layers of technology, the Xinhai High-Efficiency agitation tank achieves comprehensive superiority over traditional products.

In the flotation circuit of the 1000t/d gold-silver ore project in Peru, Xinhai Mining's GBJ3000×3000 High-Efficiency Agitation tank was successfully applied in the core pre-treatment stage before flotation. The powerful agitation and circulation capabilities of this equipment solved the uneven mixing issues of minerals, reagents, and air common with traditional agitation tanks, providing fully mineralized feed for the subsequent flotation operation.

Production data indicated that after implementing the Xinhai High-Efficiency Agitation tank, the operational stability of the flotation system significantly improved, and the final gold and silver recovery rates steadily increased by over 1% compared to the original solution. This breakthrough in a key performance indicator directly translated into substantial economic benefits for the client, powerfully validating the decisive value of the high-efficiency agitation tank in enhancing the efficiency of the entire flotation system.

The success of the gold-silver ore project in Peru clearly demonstrates the overwhelming advantages of the Xinhai High-Efficiency Agitation Tank compared to traditional equipment. It has brought customers not only an improvement in mineral processing recovery rates but also tangible economic benefits.

For 30 years, Xinhai Mining has been deeply rooted in the mineral processing industry. Our technical R&D capabilities, in particular, have gained recognition from many clients. When a product can bring genuine, tangible benefits to customers, its true value is demonstrated – this is the ultimate goal Xinhai strives for. If you are currently selecting an agitation tank, please contact us for more product information.