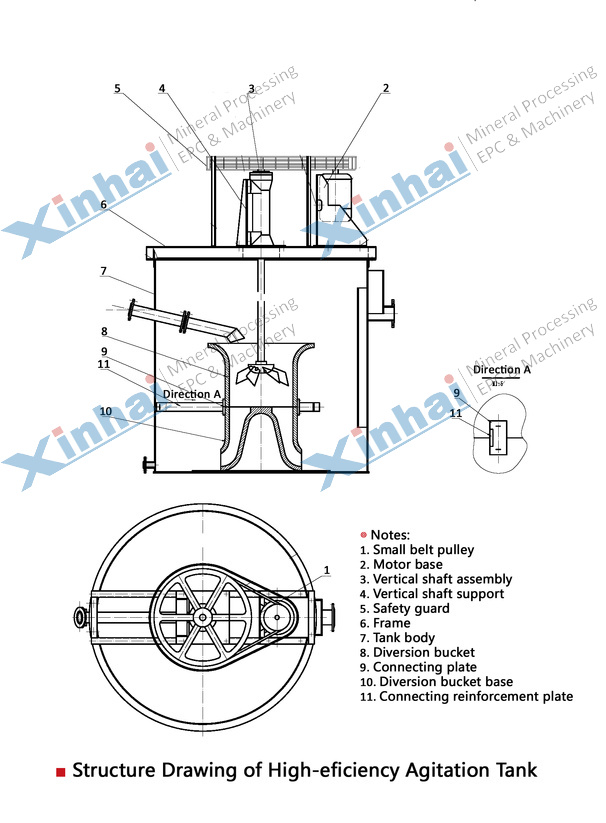

A stirring device that forces the pulp to circulate up and down in the tank. 【Processing capacity】: 0.58~45m³ 【Scope of application】: It is mainly used for slurry stirring before flotation operation, so that the agent and the slurry can be fully mixed. It can also be used in chemical and building materials industry slurry mixing and cyanide plants, sewage treatment plants and other industrial sectors.

The impeller diameter is large, the rotation speed is fast, and the stirring ability of pulp and medicine is strong;

The enhancement of the stirring ability makes the pulp and medicine circulation ability also strengthened;

There is a guiding fluid, the larger negative compression is small in the limited space, which accelerates the suction ability, makes the medicine and mineral circulation ability stronger, and increases the suction ability and circulation ability;

The lower part of the diversion body is provided with a jet body, which further strengthens the circulation capacity of the medicine and ore, which is beneficial to improve the flotation index.

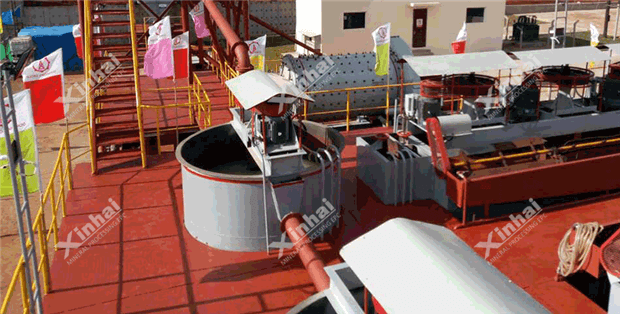

High-efficiency agitation tank is mainly applied in slurry stirring before flotation, chemical and construction industry, cyanide chemical plant, sewage treatment plant, and coal plant etc.. The rotation of the impeller drives the flowing of the slurry, which makes the mineral grains and the reagents well.

| Model | Effective Volume (m3) | Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model | Motor Power (kW) | Weight (kg) |

| GBJ-1000X1000 | 0.58 | 530 | 240 | Y112M-6 | 2.2 | 548 |

| GBJ-1250X1250 | 1.15 | 350 | 240 | Y100L2-4 | 3 | 820 |

| GBJ-1500X1500 | 2.2 | 320 | 420 | Y132M2-6 | 5.5 | 1350 |

| GBJ-2000X2000 | 5.46 | 240 | 560 | Y160M-6 | 7.5 | 3173 |

| GBJ-2500X2500 | 11.2 | 232 | 560 | Y180L-6 | 15 | 3939 |

| GBJ-3000X3000 | 19.1 | 220 | 700 | Y225S-8 | 18.5 | 6676 |

| GBJ-3500X3500 | 31 | 248 | 700 | Y225M-8 | 22 | 7581 |

| GBJ-4000X4000 | 45 | 153 | 1000 | Y250M-8 | 37 | 9560 |

A gold mine dressing plant in Guangxi used a traditional slurry stirring tank in the process of slurry mixing and dosing. The stirring force was not strong, the slurry was rotated around the vertical axis, and the chemical mixing was uneven, and the impeller was rapidly worn. Later, after consulting Xinhai Mining, Xinhai recommended a high-efficiency mixing tank for it. The umbrella-shaped impeller of this equipment has a large diameter and a large linear speed, so that the chemicals can be mixed evenly. The saving is about 20%, and the flotation index is significantly improved compared with the previous one. The impeller is made of polyurethane material, which has strong wear resistance and has achieved satisfactory results in this factory.