If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

If you run a mineral processing plant, you’ve probably encountered these issues with traditional disc feeders:

Inconsistent feeding, sometimes too much or too little, affecting the efficiency and stability of the ball mill;

Unable to adjust the feed rate in real time, leading to low recovery rates and high energy consumption;

High wear caused by abrasive iron ore materials, resulting in short service life and high maintenance costs for ordinary feeders.

The key to solving these problems lies in making the feeding process both “intelligent” and “precise.” So, is there a piece of equipment on the market that can truly achieve this? Today, we’d like to introduce the Disc Feeder manufactured by Xinhai Mining.

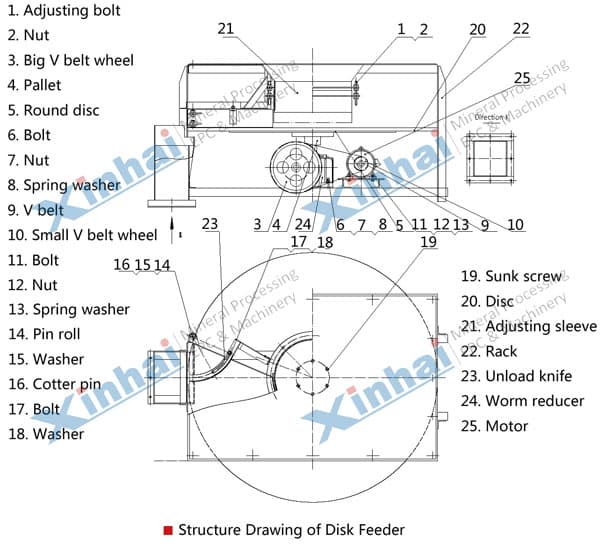

The disc feeder is a feeding device composed of a rotating disc, main shaft, sleeve, scraper, and other core components. It is suitable for feeding various non-sticky materials such as ores, cement, clinker, limestone, and slag.

Working principle: Material from the hopper enters the receiving cylinder, then falls by gravity onto the rotating disc and accumulates. A fixed discharge scraper evenly scrapes the material into the receiving chute. By adjusting the sleeve height and the gap between the scraper and the disc, the feeding volume and material layer thickness can be precisely controlled.

In traditional iron ore concentrators, the disc feeder requires manual adjustment, and the feeding accuracy and stability depend heavily on the operator’s experience. The Xinhai Disc Feeder can automatically adapt to operating conditions to ensure optimal production performance.

1. Sensing Layer

Xinhai’s disc feeder is equipped with high-precision sensors at key points to capture equipment status in real time and provide data support for decision-making:

Load sensors continuously monitor the total material load on the disc;

Radar or ultrasonic level meters monitor the material height in the storage bin to predict feeding demand in advance;

Speed sensors accurately detect the actual rotational speed of the disc and feed the signal back to the control system.

2. Control Layer

PLC Central Control System: The Xinhai Disc Feeder adopts a PLC-based central control system that receives data from all sensors. Operators can set the target feeding rate and process parameters via a touch screen. The PLC compares real-time data with the set parameters and, based on its built-in model, determines whether to accelerate, decelerate, or maintain the current state — all automatically, without manual intervention.

Touch Screen HMI: Through this human-machine interface, operators can input target feeding parameters, reducing the risk of misoperation. Real-time process data and equipment status are displayed clearly on the screen, and the system automatically records historical data to enable accurate fault tracing when necessary.

1. How Is Precision Feeding Achieved?

The Xinhai Intelligent Disc Feeder can achieve feeding accuracy up to the kilogram level through the following control methods:

The PLC adjusts the power frequency of the drive motor to change the disc’s rotational speed — this is the fundamental physical means of achieving precise control.

Electric or hydraulic regulating valves work in coordination with variable-frequency speed control to realize a wider and more accurate feeding range.

Closed-loop control process: Set target feeding rate → PLC calculation → Adjust frequency converter and gate valve → Sensors detect actual feeding → Feedback to PLC → Dynamic compensation and correction.

2. Value of Precision Control

Stable ball mill feeding: Ensures a constant and appropriate ore supply for grinding, improving grinding efficiency and fineness.

Improved beneficiation performance: Stabilizes the feed concentration and volume for flotation, magnetic separation, and other operations, directly enhancing concentrate grade and recovery rate.

Energy saving and cost reduction: Prevents “idling” or “overloading” of equipment, reducing unnecessary power consumption and cutting electricity costs.

1. Exceptional Wear Resistance

The Xinhai Disc Feeder features inner linings made of wear-resistant ceramic or high-chromium cast iron plates. The scraper is made from surfacing-welded wear-resistant alloy, and key parts undergo special heat treatment to ensure high durability and long service life — significantly reducing maintenance costs.

2. Adaptability to Harsh Conditions

Iron ore powder tends to absorb moisture and harden, easily causing blockages in conventional equipment. The Xinhai Disc Feeder adopts anti-blocking design and dust-proof sealing structures to ensure stable operation even under harsh working conditions.

3. Customized Intelligent Control System

Xinhai’s intelligent control system can be custom-programmed based on the ore’s density, particle size, and moisture content, allowing the control model to better match real material characteristics — delivering truly intelligent performance.

4. Improved Overall Efficiency

The Xinhai Disc Feeder not only achieves precise feeding but also enhances the performance of subsequent processing stages. It improves overall production line efficiency, stabilizes product quality, and reduces operational costs — ultimately increasing the customer’s economic returns.

With its intelligent, precise, wear-resistant, and efficient design, the Xinhai Disc Feeder is the ideal feeding equipment for iron ore concentrators. Contact us today for free product technical parameters and learn more about how it can optimize your plant performance!