If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

A hydrocyclone is a key tool in today’s mineral plants. It’s small, has no moving parts, and handles huge amounts of slurry fast. It plays a big role in grinding circuits, removing slimes, and managing tailings. This guide dives into the hydrocyclone working principle, explains its design and operating factors, and lists common hydrocyclone applications in mining. We’ll also share tips to boost hydrocyclone efficiency and a real-world hydrocyclone case study. Plus, we’ll cover hydrocyclone maintenance and hydrocyclone troubleshooting to keep operations smooth and profitable. For gold miners, we’ll highlight how it fits into the grind-to-leach process under hydrocyclone in gold processing. Honestly, it’s a game-changer when used right.

A hydrocyclone is a cone-shaped device that takes in slurry through a side inlet. It spins the slurry to create a swirling motion. This motion uses centrifugal force to separate materials. Fine, light particles go to a “overflow” at the top. Coarse, heavy ones exit through an “underflow” at the bottom. In hydrocyclone in mineral processing, this separation controls grind size, cleans out slimes, concentrates heavy fractions, or dries tailings. These tasks directly affect how much metal you recover, how many chemicals you use, and how much power your plant needs.

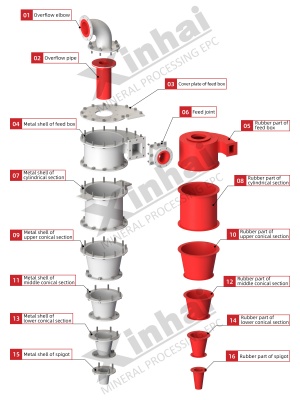

The hydrocyclone gets slurry through a side pipe. This makes the slurry spin fast inside the cone. The spinning forms two flows: a heavy outer spiral going down and a light inner spiral going up. Parts like the feed head, cylinder, cone, vortex finder, and apex decide the cut size (d50), which is the size where particles split evenly. Here’s the breakdown:

Main forces: Centrifugal pull (from spinning speed), drag, and buoyancy push particles around.

Flow paths: Heavy stuff spirals down to the apex. Light stuff spirals up to the overflow.

Cut size tweak: Pressure, slurry thickness, cyclone size, and internal parts control the split.

Grasping the hydrocyclone working principle helps you adjust splits, reduce fines in the underflow, and keep the mill’s load steady.

Hydrocyclones shine in tasks needing size or density splits at high volumes. Key hydrocyclone applications in mining include:

Grinding circuit control: Sends coarse particles back to SAG or ball mills and fines forward.

Desliming: Strips out clay and tiny particles that mess up flotation or filtering.

Dewatering: Thickens tailings or mid-process streams for easier handling.

Pre-concentration: Uses density or shape to upgrade ore before flotation or gravity units.

Scalping oversize: Blocks large chunks from damaging downstream gear.

In gold, copper, or other mineral plants, picking the right cyclone and controlling it well can make or break your recovery goals. It’s like the unsung hero of the flowsheet.

Good performance comes from both the cyclone’s shape and how you run it. To improve hydrocyclone design for better hydrocyclone efficiency, think about these:

Size: Smaller cyclones make finer cuts but handle less slurry and need more pressure. Bigger ones process more but cut coarser.

Vortex finder: A longer or narrower finder tightens the split by steadying the inner swirl. Too tight, though, and it clogs the overflow.

Cone shape: Steep cones give coarser cuts and drier underflows. Flatter cones help with fine separations.

Apex size: A bigger apex lets more underflow out, but risks sending fines the wrong way. A smaller one might thicken too much and clog.

Inlet shape: Smooth inlets cut turbulence, save energy, and make cleaner splits.

You can also tweak operations to shift the cut:

Pressure: Usually 0.1–0.35 MPa in most circuits. Higher pressure often gives finer cuts, but too much wears parts fast.

Slurry thickness: Thicker slurry can coarsen the cut. Too thin, and efficiency drops.

Particle traits: Size, shape, and density affect how clean the split is.

Heat and stickiness: Warmer slurry is less sticky, which can help fines flow to the overflow.

Nailing the hydrocyclone classification process means balancing capacity, clean cuts, and steady operation to hit the right grind size.

Knowing the hydrocyclone advantages and disadvantages helps you pick it over, say, a spiral classifier or screen.

No moving parts, so it’s simple and takes little space.

Handles tons of slurry in a small footprint. Easy to group for bigger jobs.

Quickly adjusts to pressure or slurry changes, great for automated control.

Flexible: works for classifying, desliming, dewatering, or concentrating.

Wear at the inlet, cone, and apex. You need tough liners.

Picky about slurry changes, which can mess up the cut size.

Fines can sneak into the underflow if not watched.

Clogs (roping) if underflow gets too thick. Sprays too much if too watery.

Understanding these pros and cons lets you choose wisely and plan controls to handle the downsides.

The hydrocyclone classification process keeps mill output on target. Say a SAG/ball mill aims for 75–150 µm particles. If the overflow gets too coarse, the mill’s load drops, and you might not liberate enough metal. Too fine, and you waste power while creating slimes that hurt recovery. Cyclone clusters with auto-pressure and density controls keep things tight, so the mill runs efficiently.

In gold plants, the hydrocyclone in gold processing sets up the grind for leaching or flotation. It ensures particles are the right size for carbon-in-pulp (CIP) or carbon-in-leach (CIL). This cuts chemical use and boosts gold liberation, so downstream steps like adsorption or electrowinning recover more gold with less waste.

Good design ties equipment to your goals:

Cut size goal: What particle size boosts recovery? Pick cyclone size and pressure to hit it, then tweak finder and apex.

Clean separation: Smooth insides and inlets reduce turbulence for sharper cuts.

Water balance: Adjust water to keep underflow thick but not clogged.

Cluster setup: Use backup banks and valves to stay steady during maintenance.

Wear plan: Pick liners based on ore abrasiveness and pH. Keep spares ready.

Picture a copper-gold plant wanting a finer grind to speed up flotation. They swapped a mixed-size cyclone cluster for uniform 250 mm units, extended vortex finders, and tweaked apex sizes by 1–2 mm steps. They added tight pressure control (±5 kPa) and water to adjust density. Here’s what happened in this hydrocyclone case study:

Overflow P80 dropped from 165 µm to 140 µm with less variation.

Circulating load steadied at 250–270% (used to swing from 180–320%).

Flotation recovery climbed 1.2–1.8%, without using more power.

Underflow got 2–3% thicker, helping dewatering later.

The changes paid off in months through more metal and fewer shutdowns. It’s proof small tweaks can bring big wins.

Steady operation needs regular hydrocyclone maintenance and quick hydrocyclone troubleshooting.

Liner checks: Measure wear often. Replace before cuts drift.

Inlet and nozzle: Look for damage or buildup.

Pressure sensors: Calibrate them. Clean lines to avoid errors.

Cluster balance: Ensure even slurry flow to each cyclone.

Spares: Stock key parts and standardize sizes for simplicity.

| Symptom | Likely Causes | Actions |

|---|---|---|

| Underflow roping (thick, pencil-like stream) | Apex too small, slurry too thick, low pressure | Widen apex, add water, boost pressure safely |

| Underflow sprays too much (watery) | Apex too big, pressure too high, slurry too thin | Shrink apex, lower pressure, cut water |

| Overflow too coarse | Worn finder or cone, low pressure, thick slurry | Replace worn parts, adjust pressure, thin slurry |

| Too many fines in underflow | Short-circuiting, turbulent inlet, rough insides | Fix inlet shape, smooth insides, adjust finder |

| Blockages keep happening | Debris, scale, or oversize feed | Add screens, clean scale, control upstream |

It’s mainly for sorting sizes, removing slimes, drying tailings, or concentrating ore. These keep grinding circuits steady and boost downstream recovery.

It spins slurry to create centrifugal force. Heavy particles slide to the wall and exit the bottom. Light ones spiral up to the top.

Grinding circuits and desliming before flotation give the best gains in metal recovery and energy savings.

It ensures the right grind size for leaching or flotation, cutting chemical use and boosting gold recovery downstream.

Getting the hydrocyclone in mineral processing dialed in can totally change your plant’s game. It keeps grinding steady, ramps up metal recovery, and cuts energy costs. Pick a hydrocyclone design that fits your targets, keep an eye on hydrocyclone efficiency, and use smart tech to stay on track. Stick to routine hydrocyclone maintenance and quick hydrocyclone troubleshooting to keep things humming. For gold operations, the hydrocyclone in gold processing sets you up for better leaching results. Get to know the hydrocyclone advantages and disadvantages so you can use it where it really rocks. For top-notch performance, go with Xinhai Hydrocyclones—they’re built tough for great efficiency, reliability, and bigger yields.