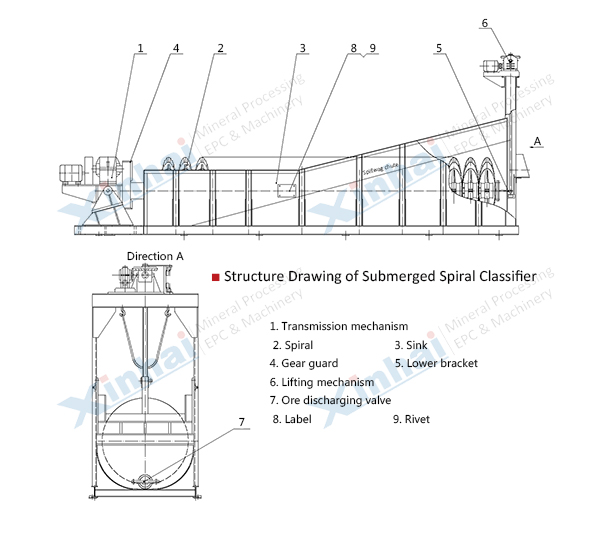

A classifier equipment in which the overflow end spiral is completely submerged under the liquid surface. 【Processing capacity】: 50~1410 t/d 【Scope of application】: The spiral blades at the overflow end of the submerged spiral classifier are all immersed below the overflow surface, which is mainly suitable for the classification of ore with overflow particle size of 0.15-0.07mm.

The whole spiral of the overflow end of the submerged spiral classifier is sunk below the liquid level of the settlement area, and the settlement area has a large area and depth;

Generally, 1-1.5 degrees of electricity can be saved per ton of ore;

Avoid frequent maintenance of the big spoon;

The uneven impact on the large and small gears is slowed down.

The spiral classifier working principle: Fine ore pulps are fed into a water tank through feeding opening located in the center of settling zone. Beneath the inclined a water tank is the ore pulp classification zone where ore pulps are stirred by low-speed impellers. Fine ore particles are lifted up and then spilled out the overflow opening; coarse ore particles precipitate down to the tank bottom and are discharged via discharge opening.

| Type | Model | Rotating Speed of Spiral (r/min) | Capacity of Sand Return (t/d) | Capacity of Overflow (t/d) | Spiral Diameter (mm) | Spiral Length (mm) | Slope of Water Tank | Drive Motor Model | Drive Motor Power (kW) | Lifting Motor Model | Lifting Motor Power (kW) | Weight (kg) |

| SubmergedSingle Spiral Classifier | FLC-1000 | 2.5~7.4 | 160~700 | 50-260 | Φ1000 | 8397 | 14 ~18 | Y132M2-6 | 5.5 | Manual driven | — | 5225 |

| FLC-1200 | 5~7 | 1150~1640 | 120 | Φ1200 | 8400 | Y160M-6 | 7.5 | Y90L-4 | 1.5 | 9583 | ||

| FLC-1500 | 2.5 ~6 | 1140~2740 | 185 | Φ1500 | 10500 | Y100L1-4 | 2.2 | 14226 | ||||

| FLC-2000 | 3.6~5.5 | 3240~5940 | 320 | Φ2000 | 13000 | Y160L-4 | 15 | Y100L2-4 | 3 | 27753 | ||

| FLC-2400 | 3.6 | 6800 | 455 | Φ2400 | 14130 | Y200L1-6 | 18.5 | Y112M-4 | 4 | 32467 | ||

| FLC-3000 | 3.2 | 11650 | 705 | Φ3000 | 14300 | Y200L-4 | 30 | Y112M-4 | 4 | 43500 | ||

| SubmergedDouble SpiralsClassifier | 2FLC -1200 | 3.8 ~6 | 1770~2800 | 240 | Φ1200 | 8040 | Y160M-6 | 7.5X2 | Y100L1-4 | 2.2X2 | 19610 | |

| 2FLC-1500 | 2.5 ~6 | 2280~5480 | 370 | Φ1500 | 10500 | 27450 | ||||||

| 2FLC-2000 | 3.6,5.5 | 7780~11880 | 640 | Φ2000 | 12900 | Y200L2-6, Y200L-4 | 22;30 | Y100L2-4 | 3.0X2 | 50621 | ||

| 2FLC-2400 | 3.67 | 13700 | 910 | Φ2400 | 14130 | Y25S-4 | 37 | Y112M-4 | 4.0X2 | 65283 | ||

| 2FLC-3000 | 3.2 | 23300 | 1410 | Φ3000 | 14300 | Y225M-4 | 45 | Y112M-4 | 4.0X2 | 84900 |

Tanzania is located in southern Africa and has a savanna climate with high air humidity, and many machines are often eliminated due to rust. For a gold mine project in Tanzania, the demand for ore sorting is not particularly large, but the requirements for ore particle size are relatively strict. Xinhai selected a submerged spiral classifier for the customer according to the customer's geographical location and needs. The classification overflow particle size ≤ 0.015mm, the grading effect meets customer needs, and the beneficiation recovery rate is increased by 11%.